Application Scenarios

At a copper smelter in Chile, an aging GE S70 motor protection relay began exhibiting intermittent communication failures and erratic trip behavior on a 6 MW furnace blower—a critical asset with zero tolerance for unplanned stops. Diagnostics traced the issue to degraded components on the internal logic board. After replacing the faulty unit with a genuine GE V7768-320001 A2 processor board—reprogrammed and calibrated at an authorized service center—the relay resumed stable operation with full thermal overload modeling and Modbus reporting restored. Crucially, the new V7768-320001 enabled seamless integration with the plant’s legacy DCS, avoiding a $ 250.000 full-system upgrade. This case underscores how the V7768-320001 extends the operational life of proven protection infrastructure while maintaining safety integrity in harsh, high-temperature industrial settings.

Technical Principles and Innovative Values

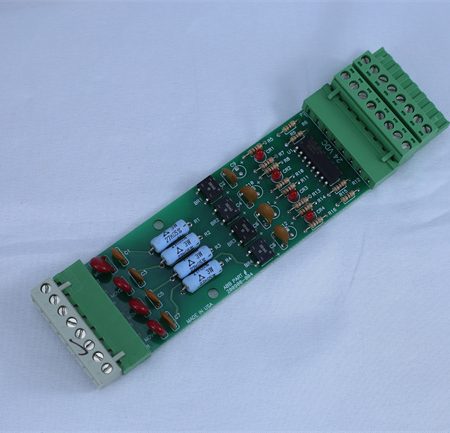

Innovation Point 1: Integrated Signal Conditioning Architecture

The V7768-320001 embeds high-precision isolation amplifiers and anti-aliasing filters directly on the processor board, eliminating external signal conditioners and reducing noise susceptibility in electrically noisy plants—key for accurate motor thermal modeling under variable load.

Innovation Point 2: Firmware-Hardware Synchronization

Unlike generic replacement boards, the V7768-320001 A2 includes hardware revision tagging that enforces compatibility with specific S70 firmware builds, preventing boot failures or miscalibration during field repairs.

Innovation Point 3: Conformal-Coated Industrial Design

The board features military-grade conformal coating (per IPC-CC-830B) to resist sulfur, moisture, and dust—proven in offshore oil platforms and cement kilns where standard PCBs corrode within months.

Innovation Point 4: Diagnostic Traceability

Built-in self-test circuits monitor power rail stability and clock integrity, logging faults to non-volatile memory—enabling root-cause analysis even after a complete power loss, a feature leveraged during forensic investigations in arc-flash events.

Application Cases and Industry Value

In a pulp and paper mill in Finland, a series of unexplained trips on hydraulic pump motors threatened production continuity. Engineers discovered that counterfeit processor boards installed during prior repairs lacked proper analog filtering, causing false overcurrent signals during VFD switching transients. After deploying genuine GE V7768-320001 A2 boards—each factory-trimmed and validated—the false trips ceased entirely. Over 14 months, the site achieved 99.98% motor availability and avoided €180.000 in potential lost production. Maintenance teams now use the board’s diagnostic logs to predict capacitor aging in auxiliary power supplies, turning reactive repairs into proactive asset management. The V7768-320001 thus proves its worth not just as a spare part, but as a guardian of process reliability in capital-intensive industries.

Related Product Combination Solutions

GE Multilin S70: Host relay platform where V7768-320001 serves as the central processing unit; ideal for medium-voltage motor protection.

GE Enervista S70 Setup: Configuration software required to program firmware and protection settings after V7768-320001 installation.

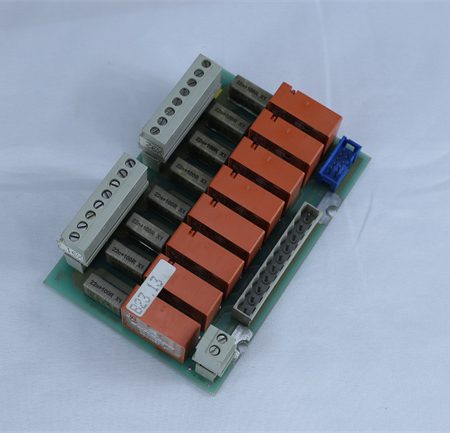

GE V7768-310001: Power supply subassembly often replaced alongside V7768-320001 during full S70 refurbishment.

GE Multilin 750: Modern IEC 61850-ready successor to S70; recommended for new installations seeking cybersecurity and digital substation readiness.

GE S70-FACEPLATE: Front panel assembly compatible with V7768-320001-equipped units for HMI restoration.

ABB PSTX Softstarter: Frequently protected by S70 relays using V7768-320001 logic for coordinated motor starting and overload protection.

Honeywell CC-TDID01: Digital input module that can monitor S70 alarm contacts driven by V7768-320001 logic in hybrid DCS/SIS architectures.

Rockwell PowerFlex 755: AC drive whose motor circuit is commonly safeguarded by S70 relays powered by the V7768-320001 processor board.

Installation, Maintenance, and Full-Cycle Support

Installation of the GE V7768-320001 must be performed by trained personnel in a static-controlled environment. The board is seated into the S70 chassis backplane, secured with EMI gaskets, and connected to internal ribbon cables. Critically, post-installation steps include loading the correct firmware via Enervista S70 Setup, re-entering CT/VT ratios, and executing a full calibration sequence—omitting these steps risks protection misoperation. The V7768-320001 A2 revision includes enhanced thermal vias and updated decoupling capacitors, improving longevity in >60°C environments compared to earlier versions.

For maintenance, the V7768-320001 should only be replaced as part of a comprehensive relay health assessment. We recommend pairing board replacement with cleaning of relay contacts, verification of CT burden, and functional testing per IEEE C37.90. As an authorized GE Vernova service partner, we supply only factory-tested V7768-320001 A2 units, each validated for:

Signal path accuracy (±0.5% @ 5 A)

Modbus response latency (<10 ms)

Power-on self-test pass/fail consistency

Conformal coating thickness (25–50 µm per MIL-I-46058C)

Our full-cycle support includes firmware recovery, obsolescence migration planning to Multilin 750. and rapid exchange programs for critical spares—ensuring your legacy protection systems remain safe, compliant, and operational.

Contact us for a customized solution—whether you’re restoring a failed S70 relay, managing a fleet of legacy motor protectors, or planning a phased migration to modern IEDs, the genuine GE V7768-320001 delivers the authenticity, reliability, and technical backing your industrial operations demand.

.jpg)

.jpg)

Reviews

There are no reviews yet.