Application Scenarios:

In a high-speed rotary printing press, the precise registration of colors is critical. Even a minute timing error between printing cylinders results in blurred, misaligned images and costly material waste. A Hengstler SYHNC100-NIB-24-P-D-E23-A012 encoder is mounted directly on the main impression cylinder shaft. Its robust 100mm housing withstands constant vibration, while its 24mm hollow shaft allows for secure, direct mounting, eliminating coupling backlash. The encoder’s SSI output transmits absolute position data with clock-synchronized precision, immune to the electrical noise from nearby high-power motor drives. This enables the press’s control system to maintain perfect electronic gearing between all color stations, ensuring razor-sharp print quality at maximum production speeds. This application highlights the encoder’s role in solving key pain points: achieving micron-level synchronization, operating reliably in harsh industrial environments, and eliminating quality defects.

Technical Principles and Innovative Values:

Innovation Point 1: Synchronous Serial Interface (SSI) for Uncompromised Data Integrity. Unlike standard incremental encoders that output a pulse train susceptible to noise and pulse loss, the SYHNC100-NIB-24-P-D-E23-A012 employs an SSI interface. The controller sends a clock signal, and the encoder synchronously returns a complete, absolute position value as a serial data word. This method is exceptionally robust over long distances in electrically noisy environments, ensuring the control system always receives accurate position data without cumulative error, which is critical for precision synchronization and absolute positioning within one revolution.

Innovation Point 2: Integrated Hollow Shaft Design for Direct, Accurate Coupling. The encoder features a 24mm through-bore hollow shaft. This design allows it to be mounted directly onto the machine shaft and secured with a clamping flange, eliminating the need for flexible couplings or mounting brackets. This direct connection provides superior torsional stiffness, minimizes mechanical play, and ensures the feedback signal is a true and instantaneous representation of the shaft’s position. It simplifies installation, reduces potential points of failure, and enhances overall system accuracy.

Innovation Point 3: Industrial-Grade Construction for Maximum Durability. Housed in a sturdy 100mm diameter metal casing, the SYHNC100-NIB-24-P-D-E23-A012 is built for harsh factory conditions. It typically boasts a high ingress protection rating (e.g., IP65/IP67), making it resistant to dust, oil, and coolant spray. High-grade bearings ensure long life under significant radial and axial loads. This ruggedness guarantees reliable operation in challenging applications like paper mills, steel processing, or outdoor machinery, minimizing downtime and maintenance costs.

Application Cases and Industry Value:

A global manufacturer of corrugated cardboard was struggling with inefficiencies on their rotary die-cutters. Inaccurate feed length control, caused by unreliable encoder feedback from vibrating mechanics, led to mis-cuts and over 8% material waste. They retrofitted the main feed axis with a Hengstler SYHNC100-NIB-24-P-D-E23-A012 encoder. The direct hollow-shaft mounting eliminated coupling backlash, while the SSI interface provided rock-solid position data unaffected by the electrical noise from the nearby high-current servo drives. The result was a transformative improvement: cut-to-print registration accuracy improved by over 90%, and material waste plummeted to less than 1%. The plant manager stated, “The SYHNC100-NIB-24-P-D-E23-A012 gave us the reliable data our control system desperately needed. We’ve not only saved millions in cardboard waste annually but also increased machine throughput by enabling higher, more confident operating speeds.” This demonstrates the encoder’s direct value in driving significant cost savings, quality improvement, and productivity gains.

Related Product Combination Solutions:

Hengstler RI 58-O/1000EK.26IR: A robust incremental encoder with a blind hollow shaft. It’s a complementary solution for applications where a through-bore is not required, offering similar durability in a different form factor.

Hengstler AD36/12EKA.41S: A compact absolute multiturn encoder. For applications requiring absolute position over multiple revolutions without a battery, this model provides a different technological solution within the Hengstler portfolio.

SICK DFS60A-S1CA30000: A high-resolution absolute singleturn encoder. This represents a competitor’s solution for high-precision absolute positioning, highlighting the technological choice between SSI and other absolute protocols.

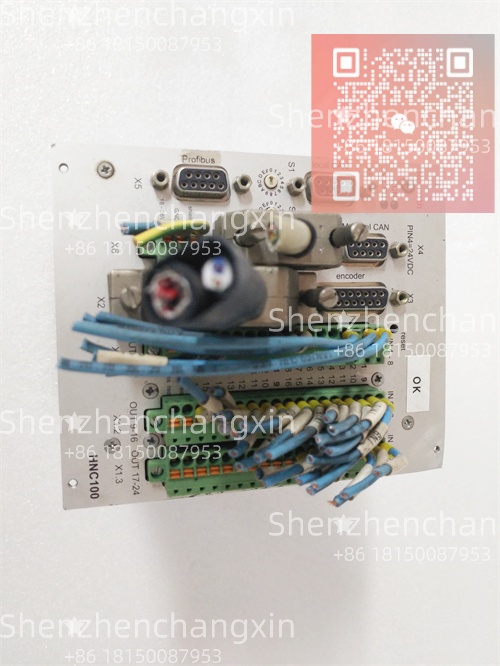

IFM E30312: An industrial SSI interface module for a PLC. This device would be the communication partner in the control cabinet, receiving and processing the SSI data from the SYHNC100-NIB-24-P-D-E23-A012.

Turck BL20 Gateway with SSI Module: A modular I/O system that can interface SSI encoders to various fieldbus networks like Profinet or EtherNet/IP, enabling easy integration of the SYHNC100-NIB-24-P-D-E23-A012 into modern control architectures.

Kübler 8.5860.xxxx.xxxx: Another series of high-duty hollow shaft encoders. It serves as a potential alternative or cross-reference, emphasizing the competitive landscape for rugged position feedback.

Pepperl+Fuchs VBG-** Series: Inductive ring kits for non-contact sensing. In some cases, these might be used in conjunction with or as an alternative to encoders for specific sensing tasks near the SYHNC100-NIB-24-P-D-E23-A012’s installation point.

Installation, Maintenance, and Full-Cycle Support:

Installation of the Hengstler SYHNC100-NIB-24-P-D-E23-A012 requires careful mechanical alignment. The hollow shaft must slide cleanly onto the machine shaft without force. The clamping flange should be tightened evenly to the specified torque to secure the encoder without distorting the housing, ensuring smooth rotation. Electrically, the shielded cable must be properly grounded at the controller end, and the SSI clock and data lines must be connected correctly to the receiving interface module. Protecting the cable from sharp bends, stress, and excessive heat is crucial for long-term reliability.

Routine maintenance is minimal due to its sealed design. Primary tasks involve periodic visual inspection for physical damage, ensuring the connector is secure, and checking that the mounting remains tight. The encoder’s bearings are lifetime-lubricated and sealed. Should a failure occur, diagnosis typically involves checking supply voltage, signal output with an oscilloscope, and ruling out mechanical issues like a bent shaft. Replacement is straightforward: note the exact model and variant code, disconnect the cable, loosen the clamping flange, and reverse the installation steps. We supply fully tested and certified Hengstler SYHNC100-NIB-24-P-D-E23-A012 encoders. Our technical support can assist with model verification, wiring diagrams, and integration advice to ensure a seamless replacement and restore your system’s precision performance.

Contact us for your Hengstler SYHNC100-NIB-24-P-D-E23-A012 encoder requirements and for expert support in optimizing your motion feedback systems.

Reviews

There are no reviews yet.