Technical Principles and Innovative Values

Innovation Point 1:The IC200UAL005 integrates CPU,power interface,and I/O into a single compact unit—eliminating the need for separate modules in small systems.This all-in-one design reduces panel space by up to 50%compared to traditional rack-based PLCs,making it ideal for tight enclosures in packaging or material handling equipment.

Innovation Point 2:Despite its size,the IC200UAL005 includes dual communication ports:RS-232 for legacy HMI or barcode readers,and Ethernet for modern connectivity.This dual-port capability allows simultaneous programming,HMI interaction,and data exchange—enabling future scalability without hardware changes.

Innovation Point 3:The IC200UAL005 is part of the larger VersaMax ecosystem,meaning it can seamlessly expand by connecting to additional I/O modules(e.g.,IC200MDLxxx)via a local bus.This“grow-as-you-need”flexibility allows users to start small and scale up—protecting their investment over time.

Innovation Point 4:Engineered for ease of use,the IC200UAL005 supports GE VersaPro,a user-friendly programming environment with drag-and-drop logic building,simulation,and diagnostics.Its intuitive interface reduces engineering time and lowers the learning curve for technicians maintaining the system.

Application Cases and Industry Value

In a Midwest warehouse automation project,the IC200UAL005 was deployed to control a series of conveyor diverters and sorting gates.The compact size allowed installation directly inside junction boxes near the conveyor lines,reducing long field wiring runs.Using its onboard inputs,the IC200UAL005 read signals from proximity sensors;its outputs triggered pneumatic actuators.The Ethernet port connected to a central SCADA system for real-time status monitoring.Over two years of 24/7 operation,the controller demonstrated 100%reliability,with no unplanned outages.Maintenance staff praised its clear LED status indicators and easy troubleshooting via VersaPro—reducing mean repair time by 60%.

Another case involved retrofitting an old HVAC fan array in a commercial building.The original electromechanical timer failed frequently.Replacing it with a IC200UAL005-based control system enabled precise fan sequencing,runtime logging,and remote alarm notification via Ethernet.The facility manager reported a 30%reduction in service calls and improved occupant comfort—proving that even micro controllers can deliver measurable energy and operational benefits.

Related Product Combination Solutions

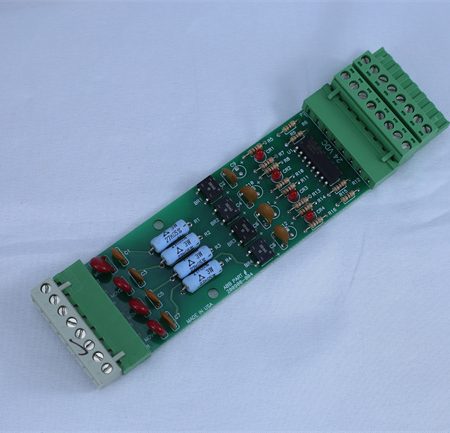

IC200MDL640:16-point digital input module–expands input capacity when more sensors are needed beyond the IC200UAL005’s onboard 6 inputs.

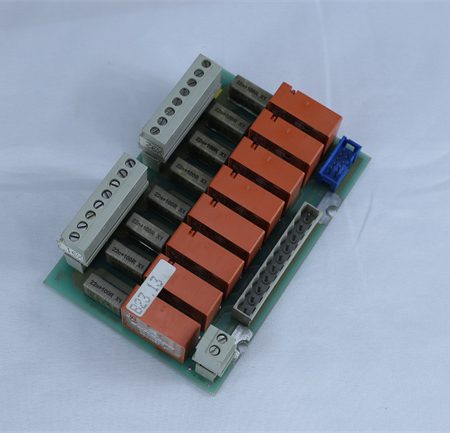

IC200MDL740:16-point digital output module–adds relay or transistor outputs for controlling larger loads like contactors or alarms.

IC200PWR001:24VDC power supply module–provides stable power in systems with multiple I/O expansions.

IC200ALG220/IC200ALG264J:Analog input modules–enable the IC200UAL005 to monitor temperature,pressure,or flow when connected via expansion bus.

IC200CPU001:Higher-end CPU for VersaMax Micro systems–a scalable upgrade path when more memory or performance is required.

VersaPro Programming Software:Essential for programming,debugging,and monitoring the IC200UAL005–supports full IEC 61131-3 functionality.

IC200GBI001:Bus interface module–connects the IC200UAL005 to a full VersaMax I/O rack for larger system integration.

HMIGXO2312:GE HMI panel–pairs with the IC200UAL005 via Ethernet or serial for operator interface and system visualization.

Installation,Maintenance,and Full-Cycle Support

Installing the IC200UAL005 is straightforward:mount it on a 35mm DIN rail,connect the 24VDC power supply,and link field devices to the onboard screw terminals.No complex configuration is needed for basic operation—power up,download the program via Ethernet or serial,and go.The front-panel LEDs(RUN,STOP,ERROR)provide instant visual feedback on system status,enabling quick diagnostics.For expanded I/O,simply daisy-chain compatible modules using the built-in bus connector.

Routine maintenance of the IC200UAL005 is minimal—typically limited to periodic inspection of terminal tightness and environmental conditions(dust,humidity).The solid-state design ensures long service life with no moving parts to wear out.If replacement is ever needed,the module is hot-swappable in most configurations,minimizing downtime.Our technical support team provides comprehensive assistance with programming,troubleshooting,and system optimization.We also offer firmware updates,training resources,and lifecycle management to ensure your IC200UAL005 remains a reliable automation cornerstone for years to come.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.