Application Scenarios

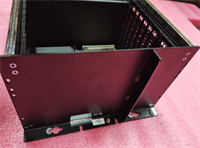

At a municipal wastewater treatment plant in the Midwest, aging relay panels caused frequent process interruptions during peak flow events. The facility upgraded to a modern SCADA-integrated control system using GE Series 90-70 PLCs housed in IC697CHS770 chassis units. Each IC697CHS770 was configured with dual IC697PWR711 power supplies and a mix of analog, digital, and HSC modules to manage pumps, aerators, and chemical dosing. During a summer storm that knocked out one power feed, the redundant supply in the IC697CHS770 seamlessly took over—keeping all 12 basins under automated control without operator intervention. Over three years, system uptime reached 99.98%, proving the IC697CHS770 as a dependable foundation for public infrastructure resilience.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True Redundant Power Architecture – The IC697CHS770 features two physically isolated power slots that allow hot-swappable, load-sharing redundant supplies (e.g., IC697PWR711). If one fails, the other instantly assumes full load without voltage sag—critical for uninterrupted logic execution in safety-related processes.

Innovation Point 2: Optimized Thermal Management – Unlike basic racks, the IC697CHS770 incorporates vertical airflow channels and vented side panels that passively dissipate heat from high-power modules like CPUs and analog cards—extending component life in enclosed cabinets without forced cooling.

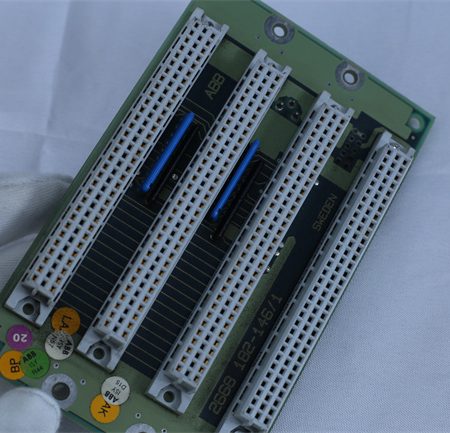

Innovation Point 3: Robust Backplane Design – The gold-plated edge connectors and reinforced PCB structure ensure reliable signal integrity even under vibration (tested to 2g), making the IC697CHS770 suitable for turbine control rooms or pumping stations with mechanical noise.

Innovation Point 4: Legacy-to-Modern Bridge – While part of the mature 90-70 series, the IC697CHS770 remains compatible with newer communication modules (e.g., IC697CMM742 for Ethernet/IP), enabling phased migration without full system replacement—preserving capital investment.

Application Cases and Industry Value

In a hydroelectric dam in the Pacific Northwest, turbine governor controls relied on a 20-year-old 90-70 system housed in IC697CHS770 chassis units. Despite the age, the plant avoided costly rip-and-replace by upgrading only the communication layer—adding IC697CMM711 modules to connect the IC697CHS770-based PLCs to a modern historian via Modbus TCP. The chassis’s stable backplane ensured zero signal degradation during grid-frequency transients. Over five years, the system maintained 100% availability during flood-season operations, with maintenance crews noting that “the IC697CHS770 still feels as solid as day one.” This longevity underscores its value in asset-intensive industries where reliability trumps obsolescence.

Related Product Combination Solutions

GE IC697CPU782: High-performance CPU module—fits slot 1 of IC697CHS770 for complex logic and motion tasks.

GE IC697PWR711: 120/240 V AC redundant power supply—designed specifically for dual installation in IC697CHS770.

GE IC697BEM731: Genius I/O bus controller—expands remote I/O capacity when used in IC697CHS770.

GE IC697ALG230: 8-channel analog input module—commonly deployed in IC697CHS770 for process monitoring.

GE IC697CMM742: Ethernet communication module—enables IT/OT integration for IC697CHS770-based systems.

VersaMax I/O (via IC697BEM733)—allows cost-effective expansion using distributed I/O linked to IC697CHS770.

Proficy Machine Edition: Programming software—fully supports configuration and diagnostics of IC697CHS770 racks.

GE IC697ACC702: Rack mounting kit—for secure DIN rail installation of IC697CHS770 in compact panels.

Installation, Maintenance, and Full-Cycle Support

Installing the IC697CHS770 begins with securing it to a panel or DIN rail using the provided hardware, ensuring at least 50 mm of clearance above and below for passive cooling. Power supplies are inserted into the leftmost slots first, followed by the CPU in slot 1 and I/O modules in subsequent positions. The backplane requires no configuration—modules are auto-detected based on physical position during power-up. Grounding is achieved through a dedicated terminal on the chassis frame, essential for noise immunity in electrically noisy plants.

Maintenance of the IC697CHS770 is minimal due to its solid-state, fanless design. Visual inspection of power LEDs and module seating is typically sufficient during routine checks. In redundant setups, a failed power supply can be replaced live without disrupting control logic—a key advantage in continuous processes. We offer comprehensive lifecycle services including compatibility verification for mixed-generation modules, obsolescence planning, and refurbished unit testing to OEM specifications. Every IC697CHS770 undergoes functional validation before shipment and is backed by technical documentation and global support.

Contact us for a customized solution—whether you’re maintaining a legacy 90-70 system or integrating it into a hybrid architecture, the GE IC697CHS770 delivers the durability, expandability, and reliability your industrial control infrastructure depends on.

Reviews

There are no reviews yet.