Application Scenarios

At a municipal water treatment facility in California, operators struggled to integrate 24 aging pump controllers—each using Modbus TCP—into their new ControlLogix-based SCADA system. Direct polling overloaded the main processor, causing scan-time delays and data loss. The solution: installing MOTOROLA MVI56E-MNETC modules in the local ControlLogix racks. Each MVI56E-MNETC handled up to 32 concurrent Modbus TCP sessions independently, offloading communication from the main CPU. Real-time flow, pressure, and valve status data flowed reliably into the HMI, while alarm events triggered immediate PLC responses. The plant achieved 99.98% data availability over 18 months—proving the MOTOROLA MVI56E-MNETC as a silent enabler of digital convergence in critical infrastructure.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Processor-Offload Architecture – Unlike software-based Modbus drivers that burden the PLC CPU, the MOTOROLA MVI56E-MNETC features an onboard ARM9 processor that handles all TCP stack, session management, and protocol conversion—keeping ControlLogix scan times predictable even under heavy I/O loads.

Innovation Point 2: Dual-Role Flexibility (Client + Server) – The same MVI56E-MNETC can simultaneously act as a Modbus TCP client (polling meters or VFDs) and a server (exposing PLC tags to a SCADA historian)—eliminating the need for separate gateways.

Innovation Point 3: Transparent Data Mapping to ControlLogix Tags – Using ProSoft Configuration Builder, users map Modbus registers directly to ControlLogix data tables (e.g., INT, REAL, BOOL arrays). No ladder logic parsing is required—the module writes data directly to user-defined tags via the backplane.

Innovation Point 4: Advanced Diagnostics and Recovery – The MVI56E-MNETC logs connection errors, timeout counts, and packet statistics. If a remote device reboots, it automatically re-establishes sessions without PLC intervention—critical for unattended sites.

Application Cases and Industry Value

In a Canadian oil sands extraction plant, a fleet of 18 variable-frequency drives (VFDs) from multiple vendors communicated only via Modbus TCP. Integrating them into the central ControlLogix safety system was deemed too complex—until engineers deployed MOTOROLA MVI56E-MNETC modules at each substation. Each module polled local VFDs for speed, torque, and fault codes, then published the data to the main PLC and a PI System historian. During a sand slurry line blockage, real-time torque spikes detected by the MVI56E-MNETC triggered an automatic ramp-down, preventing motor burnout. Maintenance costs dropped 30%, and the solution became a template for all future brownfield integrations. Similarly, a European brewery used the MVI56E-MNETC to connect legacy pasteurizers to their upgraded production line, achieving full OEE visibility without replacing $ 500k of existing equipment.

Related Product Combination Solutions

ProSoft MVI56E-MCM: Modbus RTU/ASCII serial version for RS-485 field devices

MVI56E-DNP3: DNP3 protocol variant for utility substation automation

Allen-Bradley 1756-L7x: CompactLogix/ControlLogix controllers compatible with MVI56E-MNETC

ProSoft RLX2-IHW: Wireless Ethernet radio for remote MVI56E-MNETC deployments

MVI56E-GSC: Generic ASCII serial communication module for custom protocols

Rockwell 1756-EN2T: EtherNet/IP adapter—often used alongside MVI56E-MNETC in hybrid networks

ProSoft PLX32-MBTCP: Standalone Modbus TCP gateway for non-ControlLogix systems

MVI56E-MBS: Modbus TCP-to-Serial bridge module for mixed-protocol environments

Installation, Maintenance, and Full-Cycle Support

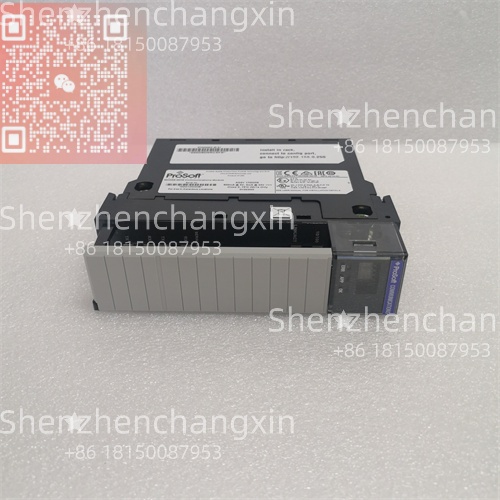

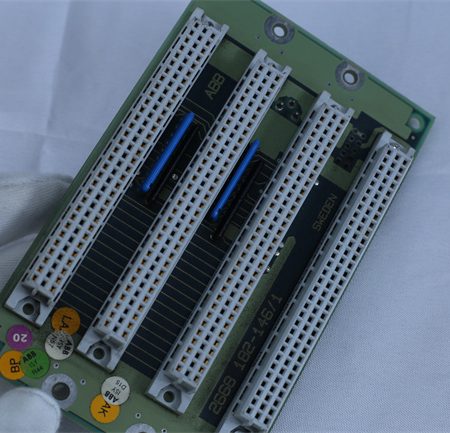

Installing the MOTOROLA MVI56E-MNETC is straightforward: insert it into any available slot in a 1756 ControlLogix chassis, secure the latch, and connect an Ethernet cable to the plant network. Power and backplane communication are automatic. Configuration begins with assigning an IP address via rotary switches or BOOTP, followed by defining Modbus maps in ProSoft Configuration Builder—then downloading the project to the module via Ethernet. No ladder logic changes are needed; data appears in pre-defined controller tags.

Maintenance is minimal due to solid-state design and industrial-grade components. The module supports firmware updates over Ethernet, ensuring compatibility with evolving network standards. LED indicators provide instant status on power, link, activity, and faults. In case of communication issues, built-in web diagnostics allow technicians to view active sessions, error counters, and register maps from any browser—no software required. Our support team provides configuration validation, network topology review, and cybersecurity hardening guidance (e.g., VLAN segmentation, port filtering). All units undergo 72-hour burn-in testing before shipment.

Contact us for seamless, secure, and scalable Modbus TCP integration with the MOTOROLA MVI56E-MNETC—the trusted backbone for connecting legacy intelligence to tomorrow’s control architectures.

Reviews

There are no reviews yet.