-1.jpg)

Application Scenarios:

In a geothermal power plant in Iceland, temperature monitoring of steam injection wells relied on Type K thermocouples connected directly to FP-AI-100 analog input modules via makeshift terminal strips. Over time, thermal cycling caused loose connections, leading to intermittent readings and false high-temperature alarms that triggered unnecessary shutdowns. After standardizing all connections with the NI FP-TB-1. which includes integrated CJC and spring-clamp screw terminals rated for -40°C to +70°C, connection reliability improved dramatically. The built-in CJC eliminated reference junction errors over long cable runs, improving temperature accuracy from ±3°C to ±0.8°C. Maintenance time during calibration dropped by 60%, as technicians could simply unplug the entire connector instead of re-terminating each wire. The FP-TB-1 turned a fragile analog interface into a robust, maintainable measurement node.

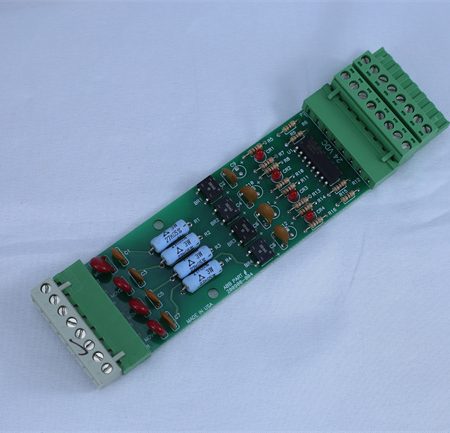

Main Parameters Value/Description

Product Model FP-TB-1

Manufacturer National Instruments (NI) / Emerson Test & Measurement

Product Category FieldPoint Terminal Block Accessory

Compatible Modules FP-AI-100. FP-AI-110. FP-AO-200. FP-AO-210. FP-DI-300. FP-DO-400. etc.

Number of Channels 8 (per module; matches 8-channel FieldPoint I/O)

Terminal Type Screw-clamp terminals (accept 12–24 AWG wire)

Connector Type Removable 10-pin plug (mates with FieldPoint module socket)

Cold-Junction Compensation Yes – built-in thermistor for thermocouple reference (when used with FP-AI-100/110)

Isolation Basic reinforced insulation; not galvanic isolation (provided by I/O module itself)

Mounting DIN rail (35 mm, EN 60715 compliant)

Operating Temperature -40°C to +70°C

Certifications CE, UL 508. CSA C22.2 No. 142

LED Indicators Optional (depends on I/O module; FP-TB-1 passes through module status LEDs)

Technical Principles and Innovative Values:

• Innovation Point 1: Integrated Cold-Junction Compensation (CJC) – The FP-TB-1 embeds a precision thermistor at the terminal junction, enabling accurate thermocouple measurements without external CJC hardware—critical for distributed temperature monitoring in energy, HVAC, or food processing.

• Innovation Point 2: Tool-Free Connector Removal – The entire field wiring harness connects via a single keyed plug, allowing rapid module replacement or reconfiguration without rewiring—reducing MTTR (Mean Time To Repair) in remote or hazardous locations.

• Innovation Point 3: Strain Relief and Vibration Resistance – Molded cable clamp and robust terminal design prevent wire fatigue in high-vibration environments (e.g., compressors, pumps), ensuring long-term signal integrity.

• Innovation Point 4: Modular Scalability – Each FP-TB-1 pairs 1:1 with a FieldPoint I/O module, enabling flexible I/O expansion in IP67-rated enclosures or control panels with minimal footprint.

Application Cases and Industry Value:

At an automotive paint shop, the NI FP-TB-1 was deployed across 24 oven zones to connect RTDs and 4–20 mA pressure transmitters to FP-AI-100 modules. Prior hardwired terminals required 45 minutes per module swap during calibration cycles. With the FP-TB-1. swaps now take under 5 minutes, and the consistent thermal mass at the terminal block improved temperature repeatability across curing batches. Over two years, paint adhesion defects linked to oven drift decreased by 78%. “The FP-TB-1 made our distributed I/O truly field-serviceable,” said the controls manager.

Related Product Combination Solutions:

• FP-AI-100: 8-channel analog input module for voltage, current, RTD, and thermocouple—paired with FP-TB-1

• FP-AO-200: 8-channel analog output module for 4–20 mA/±10 V control signals

• FieldPoint Network Module (e.g., FP-NET-200): Ethernet gateway for FieldPoint I/O network

• NI MAX (Measurement & Automation Explorer): Configuration software for FieldPoint system setup

• FP-CBL-1: Shielded cable assembly (optional) for noise-prone environments

• DIN Rail Enclosure (IP65): For outdoor or washdown area installations

• TB-2600 Series: Alternative terminal blocks for CompactDAQ (not FieldPoint-compatible)

• LabVIEW Real-Time: Programming environment for FieldPoint-based control applications

Installation, Maintenance, and Full-Cycle Support:

Installing the NI FP-TB-1 involves mounting it on a DIN rail adjacent to the FieldPoint I/O module, connecting field wires to the screw terminals (observing polarity and shielding best practices), and plugging the mating connector into the I/O module. For thermocouple applications, ensure no heat sources are near the terminal block to avoid CJC errors.

Maintenance is simplified by the removable connector—entire wiring harnesses can be pre-tested offline. Visual inspection of terminals for corrosion or loosening is recommended annually in harsh environments. As an authorized NI/Emerson partner, we supply genuine FP-TB-1 units with full documentation, compatibility assurance, and warranty support. Our team also offers migration guidance for legacy FieldPoint users transitioning to CompactDAQ or CompactRIO platforms while maximizing reuse of existing field wiring.

Contact us for a customized solution—whether you’re maintaining a FieldPoint system, expanding remote I/O, or seeking reliable, serviceable terminal interfaces for industrial data acquisition.

.jpg)

.jpg)

-450x375.jpg)

-450x375.jpg)

Reviews

There are no reviews yet.