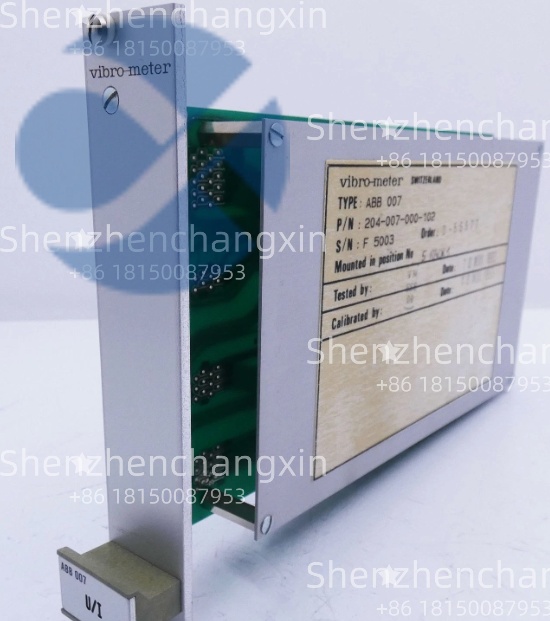

Product Overview

The Vibro-Meter 007 204-007-000-102 is a precision-engineered eddy current displacement probe designed for non-contact measurement of shaft vibration,axial position,and radial movement in high-speed rotating machinery.As a trusted component within advanced condition monitoring and machinery protection systems,the Vibro-Meter 007 204-007-000-102 delivers exceptional accuracy and reliability in demanding industrial environments.Developed under the Vibro-Meter brand,now part of ABB’s portfolio of condition monitoring solutions,this probe is widely specified in critical applications across power generation,oil&gas,and heavy industry.

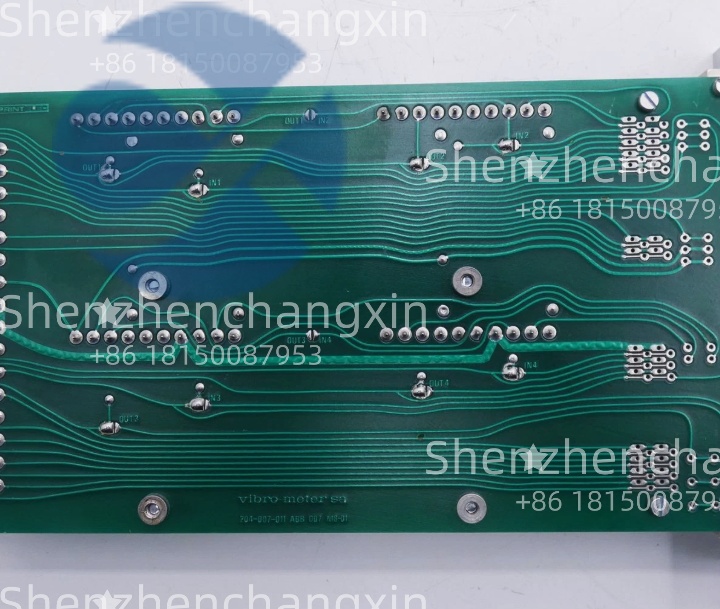

Featuring an 8mm diameter sensor tip and a robust 18-meter shielded coaxial cable,the Vibro-Meter 007 204-007-000-102 is optimized for integration with industry-standard proximitor systems such as Bently Nevada 3300 and ABB 3500 series.It operates on the principle of electromagnetic induction,where changes in the gap between the probe tip and the conductive shaft surface are converted into a proportional voltage signal.This enables real-time monitoring of dynamic shaft behavior,including unbalance,misalignment,and bearing wear.The Vibro-Meter 007 204-007-000-102 is constructed with high-grade materials to withstand extreme temperatures,vibration,and contamination,ensuring long-term stability and performance in continuous operation.

Technical Specifications

Product Model Vibro-Meter 007 204-007-000-102

Manufacturer ABB(Vibro-Meter)

Product Type Eddy Current Displacement Probe

Probe Diameter 8 mm

Cable Length 18 meters

Cable Type Coaxial,shielded with stainless steel braid

Connection Integral cable,terminated for proximitor input

Measurement Range 0 to 2 mm(typical full scale)

Sensitivity 8.0 mV/µm(200 mV/mm)on AISI 4140 steel

Frequency Response 0 Hz to>10 kHz(-3dB)

Operating Temperature(Probe)-25°C to+120°C

Operating Temperature(Cable)-55°C to+175°C

Linear Error<±1%of full scale

Output Impedance Low(matched to 50–90Ωcable)

Compatibility Bently Nevada 3300/42,ABB 3500/42,and similar systems

Main Features and Advantages

The Vibro-Meter 007 204-007-000-102 excels in performance and durability,making it a preferred choice for critical machinery monitoring.Its 8mm probe diameter offers an optimal balance between sensitivity and installation flexibility,fitting standard mounting housings while delivering high-resolution data.The 18-meter shielded cable allows for long-distance signal transmission from the machine casing to the control room or junction box,minimizing noise interference and ensuring signal integrity in electrically noisy environments.

One of the standout features of the Vibro-Meter 007 204-007-000-102 is its wide frequency response,enabling detection of both low-speed drift and high-frequency vibration events such as blade passing or bearing defects.The probe’s non-contact design eliminates mechanical wear,resulting in a long service life and consistent performance.Its high temperature tolerance on the cable jacket ensures reliability even in proximity to hot surfaces like steam lines or exhaust ducts.The Vibro-Meter 007 204-007-000-102 is also highly resistant to oil,water,and chemical exposure,maintaining accuracy in harsh process conditions.When paired with a compatible proximitor,the system provides a linear,calibrated output essential for protection relays and diagnostic analysis.This level of precision supports predictive maintenance strategies,reduces unplanned downtime,and enhances overall plant safety.

Application Field

The Vibro-Meter 007 204-007-000-102 is extensively used in applications where precise shaft dynamics monitoring is critical for equipment health and operational safety.In thermal and nuclear power plants,it monitors steam and gas turbines,generators,and feedwater pumps,detecting early signs of imbalance or rub conditions.In the oil and gas industry,the Vibro-Meter 007 204-007-000-102 is deployed on centrifugal compressors,turboexpanders,and offshore platform machinery,where failure can lead to costly shutdowns and safety hazards.

Refineries and petrochemical facilities rely on the Vibro-Meter 007 204-007-000-102 to protect critical rotating equipment such as reactors,blowers,and high-pressure pumps.Its ability to measure axial thrust position is vital for detecting thrust bearing wear in compressors.In marine propulsion systems,the probe ensures the reliability of main engines and auxiliary turbines under continuous operation.The Vibro-Meter 007 204-007-000-102 is also used in large industrial fans,motors,and paper machine drives,where vibration control is essential for product quality and machine longevity.Its integration into machinery protection systems(MPS)and condition monitoring systems(CMS)enables real-time alarming,data trending,and remote diagnostics,supporting both safety and predictive maintenance objectives.

Related Products

BENTLY 3300 XL 8mm is a comparable eddy current probe with similar specifications,designed for use in Bently Nevada systems.

ABB 3500/42 is the vibration monitor module that typically receives the signal from the Vibro-Meter 007 204-007-000-102 for processing and alarm generation.

Vibro-Meter 007 204-005-000-102 is a 5mm version of the same series,used where space is limited or lower sensitivity is required.

Vibro-Meter 007 204-011-000-102 is the 11mm diameter variant,offering higher output and longer measurement range for larger machines.

330500-00-00 is a common Bently Nevada extension cable used when field wiring requires splicing or routing flexibility.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.