The ROCKWELL AUTOMATION ICS T8800 is a rugged, fanless industrial computer engineered for mission-critical control, visualization, and data acquisition in harsh manufacturing and process environments. Built on an Intel® Core™ i7 platform with extended temperature tolerance, solid-state storage, and modular I/O expansion, the T8800 delivers enterprise-grade computing power directly on the plant floor—ideal for advanced HMI, edge analytics, machine vision, and real-time control integration within Rockwell’s Integrated Architecture.

Designed for continuous 24/7 operation in dusty, high-vibration settings, the ICS T8800 bridges the gap between traditional PLCs and IT infrastructure, enabling secure, scalable deployment of FactoryTalk applications, virtualized control, and IIoT-ready data services without compromising reliability.

Application Scenarios

At a Tier-1 automotive stamping facility in Michigan, legacy panel PCs failed monthly due to metal dust infiltration and thermal stress, causing unplanned line stops during critical press monitoring. After replacing them with the ROCKWELL AUTOMATION ICS T8800. the plant achieved 99.99% uptime over 18 months. The fanless, sealed chassis resisted particulate ingress, while its integrated FactoryTalk View SE runtime provided real-time press tonnage trending, die protection logic, and OEE dashboards—all synchronized with ControlLogix controllers via EtherNet/IP. During a bearing overheating event, the T8800’s edge analytics triggered an early warning, allowing a planned maintenance window instead of a catastrophic press crash. Engineers now deploy the ICS T8800 as the “central nervous system” for every new production cell.

Technical Principles and Innovative Values

Innovation Point 1: True Edge Intelligence with Deterministic I/O

Unlike standard industrial PCs, the ICS T8800 supports real-time hypervisor technology, enabling concurrent execution of Windows HMI, Linux-based analytics, and time-critical control tasks (e.g., SoftLogix) on a single hardware platform—reducing footprint and cost while maintaining determinism.

Innovation Point 2: Seamless Integration with Rockwell Ecosystem

Pre-validated for FactoryTalk View, Studio 5000 Logix Designer, and ThinManager, the T8800 auto-discovers ControlLogix/CompactLogix controllers over EtherNet/IP, enabling drag-and-drop tag binding and unified alarm management—cutting engineering time by up to 40%.

Innovation Point 3: Ruggedized for Extreme Industrial Environments

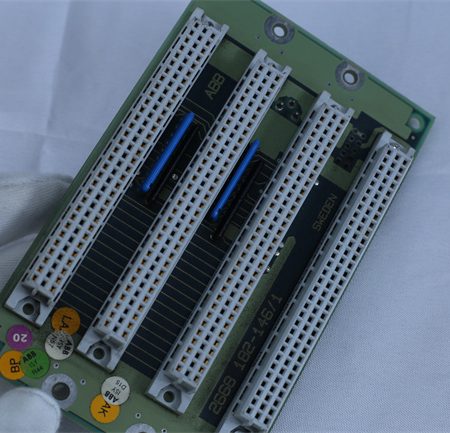

With no moving parts, conformal-coated PCBs, and wide-input DC power, the ICS T8800 withstands vibration (5–500 Hz, 2g), electrical noise (IEC 61000-4-4 Level 4), and temperature swings that cripple commercial PCs—ensuring years of maintenance-free operation.

In Innovation Point 4: Future-Ready Connectivity & Virtualization

The T8800 supports OPC UA PubSub, MQTT, and REST APIs out-of-the-box, enabling secure data flow to cloud platforms like Microsoft Azure or PTC ThingWorx. Optional virtualization allows running multiple isolated workloads—e.g., HMI, historian, and cybersecurity agent—on one box.

Application Cases and Industry Value

In a pharmaceutical packaging line in Switzerland, the ROCKWELL AUTOMATION ICS T8800 replaced three separate devices: an HMI terminal, a data logger, and a vision controller. It now runs FactoryTalk View for operator interaction, Cognex In-Sight software for label verification, and an edge historian that logs batch metadata to a central SQL server—all synchronized to the PlantPAx DCS via CIP. Audit readiness improved dramatically: electronic batch records are automatically timestamped and signed using the T8800’s TPM 2.0 security chip. The customer reported a 60% reduction in cabinet space and eliminated two annual PC replacements due to fan failure. “The ICS T8800 isn’t just a computer—it’s our compliance enforcer and productivity multiplier,” said the site automation lead.

Related Product Combination Solutions

ROCKWELL AUTOMATION 1756-L83E: ControlLogix 5580 controller—natively synchronized with the ICS T8800 via CIP and Studio 5000.

ROCKWELL AUTOMATION PanelView Plus 7: Operator terminal—can be extended or replaced by T8800-based thin clients via ThinManager.

ROCKWELL AUTOMATION 1734-AENT: POINT I/O EtherNet/IP adapter—expands local I/O when the ICS T8800 runs SoftLogix.

ROCKWELL AUTOMATION FactoryTalk View SE: Supervisory software—optimized runtime pre-installed on T8800 systems.

ROCKWELL AUTOMATION 1783-ETAP: Stratix managed switch—provides TSN and network segmentation for T8800 traffic.

ROCKWELL AUTOMATION 1732E-16CFGM12T: ArmorBlock 5000 I/O—enables decentralized connectivity for T8800-hosted applications.

ROCKWELL AUTOMATION Kinetix 5700: Servo drive system—monitored and tuned via T8800-based Connected Components Workbench.

ROCKWELL AUTOMATION 1789-AENTR: Redundant I/O adapter—supports high-availability architectures with dual ICS T8800 units.

Installation, Maintenance, and Full-Cycle Support

Installing the ROCKWELL AUTOMATION ICS T8800 is straightforward: mount it on a DIN rail or panel using the integrated brackets, connect 24 VDC power, link to the plant network, and attach displays via DisplayPort. No BIOS tuning is needed—Rockwell provides pre-configured OS images with drivers, security hardening, and FactoryTalk integration ready out of the box. Commissioning is accelerated through Studio 5000 Architect, which auto-detects the T8800 as a target device for application deployment.

For ongoing operation, the unit features remote management via Intel vPro® and AMT, enabling BIOS updates, power cycling, and diagnostics over the network—even if the OS is unresponsive. LED indicators show power, HDD activity, and network status. Maintenance is minimal: no filters to clean, no fans to replace. In case of failure, the modular design allows SSD or RAM replacement in minutes. We offer full lifecycle support including image replication tools, cybersecurity patching services, extended warranties, and migration paths from legacy VersaView or Industrial PCs. Every ICS T8800 undergoes 72-hour thermal and vibration stress testing before shipment.

Contact us for a customized solution—whether you’re modernizing legacy HMIs, deploying edge analytics, building a virtualized control platform, or seeking a future-proof industrial computer for hazardous or high-performance applications, the ROCKWELL AUTOMATION ICS T8800 delivers unmatched integration, resilience, and intelligence at the edge of your automation ecosystem.

Reviews

There are no reviews yet.