Application Scenarios

In a high-speed pick-and-place robotic cell for packaging electronics, speed, precision, and reliability are paramount. The robot’s vertical (Z) axis must rapidly lift and lower components with exact positioning. The Bosch Rexroth MKD071B-035-KG1-KN servo motor is an ideal choice for this axis. Its high torque density provides the rapid acceleration needed for fast cycle times. The integrated high-resolution encoder delivers the precise feedback required to stop the gripper at the exact millimeter for part pickup and placement. Crucially, the motor’s integrated holding brake automatically engages if power is lost, securely holding the arm and its payload in place, preventing damage to the robot or the delicate components from an uncontrolled drop. This combination of power, precision, and safety makes it a cornerstone of reliable, high-throughput automation.

Parameter

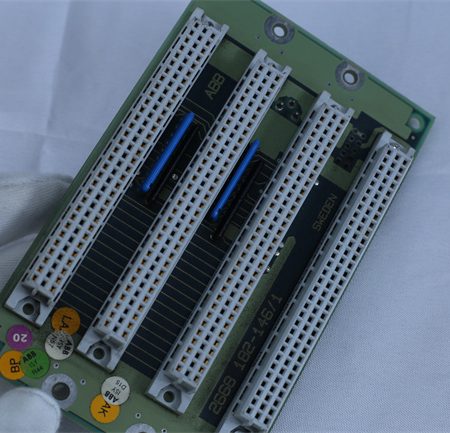

Annotation: The part number is highly descriptive. MKD071B defines the physical frame size and general type. The suffix -KG1-KN is critical: K signifies a brake, G defines the brake type/voltage, 1 is the protection class, and KN specifies the exact encoder type (e.g., HIPERFACE DSL). This must match the requirements of the drive controller (e.g., Rexroth IndraDrive).

Technical Principles and Innovative Values

The MKD071B-035-KG1-KN embodies the principles of high dynamic response, precision, and integration essential for modern servo systems.

Innovation Point 1: High Dynamic Response through Optimized Magnetic Circuit. The motor utilizes high-energy permanent magnets (often rare-earth) and an optimized stator design to achieve a high torque-to-inertia ratio. This means it can accelerate and decelerate its own rotor and the attached load very rapidly. This high dynamic capability translates directly into shorter machine cycle times, higher throughput, and the ability to execute complex, fast motion profiles accurately.

Innovation Point 2: Integrated Absolute Encoder for Absolute Precision. The “KN” in the part number specifies a high-grade, integrated absolute encoder (like HIPERFACE® or EnDat 2.2). This provides several key advantages: 1) It gives the drive controller an exact, high-resolution position value the moment the system is powered on, eliminating the need for a homing/reference move. 2) It provides single- or multi-turn absolute position data, crucial for applications requiring absolute position over long travels or multiple revolutions. 3) The digital interface provides robust, noise-immune communication of position, speed, and motor temperature data.

Innovation Point 3: Safety-Integrated Holding Brake. The integrated “KG” holding brake is a fail-safe mechanical brake. It is normally engaged (spring-applied) and disengages only when powered (electrically released). This ensures that if power is lost, the motor shaft is immediately and securely held in place. This is critical for vertical axes to prevent dropped loads, for safety in collaborative environments, and for maintaining position during power interruptions without relying on servo torque.

Application Cases and Industry Value

Case Study: Precision in a Pharmaceutical Tablet Press

A manufacturer of rotary tablet presses needed extreme precision in the indexing of the die table. Any deviation would cause inconsistent tablet weight or damage the tooling. They used Bosch Rexroth MKD071B-035-KG1-KN servo motors for the main index drive. The motor’s precise absolute encoder provided flawless angular positioning for each station stop. The high dynamic response allowed for faster indexing speeds, increasing production rates. The integrated holding brake secured the heavy die table during maintenance or power loss, preventing any creep that could misalign the delicate punches and dies. This solution reduced product waste by 0.5% and increased machine throughput by 15%, delivering a direct and significant return on investment.

Case Study: Enabling a Compact, High-Speed Delta Robot

A designer of delta robots for packaging needed to minimize the mass of the moving arms to achieve ultra-high speeds. The standard solution with a remote motor and belt drive added too much mass. They opted for a direct-drive joint using a frameless motor kit, but needed a compact, high-power rotary axis for the base. They selected a MKD071B-035-KG1-KN motor, removing its housing and integrating its rotor and stator directly into the robot’s joint. The motor’s high torque density and low rotor inertia were perfect. The absolute encoder provided direct, backlash-free joint angle feedback. This innovative integration, centered on the performance of the MKD motor, allowed the robot to achieve a 25% higher pick rate than competing models, giving the OEM a key market advantage.

Related Product Combination Solutions

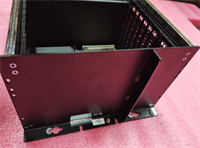

Bosch Rexroth IndraDrive HCS02.1 Drive Controller: A single-axis servo drive from the same family, perfectly matched to control the MKD071B-035-KG1-KN. It understands the motor’s encoder (HIPERFACE®) and can optimally utilize its performance.

Bosch Rexroth IndraDrive MLC Multi-Axis Controller: For systems with multiple motors, this controller can coordinate several axes, each driven by its own drive module (like an HCS) connected to a motor like the MKD071B.

Bosch Rexroth Gearbox (e.g., Planetary Gearbox): A precision gearbox (e.g., model with “G” in the name) is often coupled to the servo motor to increase output torque and reduce speed for applications like conveyor drives or heavy actuators.

Bosch Rexroth MS2N Safety Module: A safety option module that can be plugged into compatible IndraDrive controllers. It allows the drive to process safe motion functions (e.g., Safe Torque Off – STO) directly, enhancing the safety of a system using the MKD071B motor.

Bosch Rexroth Motor Cable (e.g., DKC/DKV series): A specifically shielded and configured power and feedback cable set designed to connect the MKD071B motor to its drive, ensuring optimal signal integrity and EMC performance.

Bosch Rexroth Holding Brake Resistor/Module: An external module sometimes used to manage the inrush current when releasing the motor’s integrated holding brake, protecting the drive’s power supply.

Bosch Rexroth IndraWorks Engineering Software: The comprehensive suite used to commission, parameterize, and tune the entire drive system, including automatically identifying the connected MKD071B-035-KG1-KN motor via its integrated encoder data.

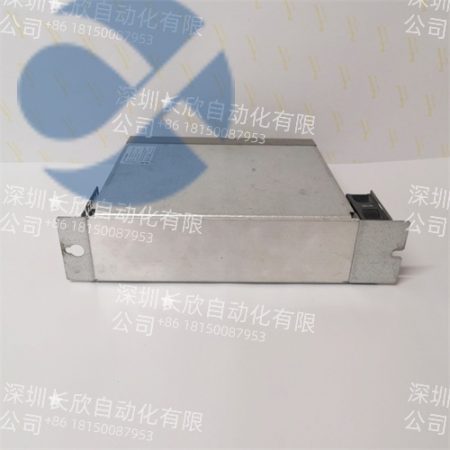

Installation, Maintenance, and Full-Cycle Support

Installation requires careful mechanical and electrical alignment. The motor must be mounted securely to a machined surface to ensure proper alignment with the load (e.g., via a coupling or gearbox) and to provide a good thermal path for cooling. The shaft must not be subjected to radial or axial forces beyond specification. Electrically, the correct, shielded motor cable must be used, and connections to the drive must be precise, following the pinout diagram exactly. The brake requires a separate DC power supply (typically 24V DC) as specified in the manual. Miswiring the brake can damage it.

Maintenance is primarily preventative. The motor is largely sealed (IP65), but the exterior should be kept clean, and cooling fins should be free of debris. The primary wear component is the bearing. While these are rated for long life, monitoring for unusual noise or vibration is recommended. The holding brake also has a specified mechanical life (number of engagements). The motor’s integrated temperature sensor, read via the encoder, can provide early warning of overload conditions. Our full-cycle support for the MKD071B-035-KG1-KN includes providing mounting dimensions and technical drawings, electrical connection schematics, assistance with troubleshooting (e.g., interpreting error codes from the drive related to the motor or encoder), and supplying genuine replacement motors or spare parts like connectors and feedback cables. We can also assist with pairing the motor with the correct drive and tuning the system for optimal performance.

To ensure peak performance and longevity of your motion system, using correctly specified and matched components is essential. Contact us for detailed datasheets, application consultation, and sourcing for the Bosch Rexroth MKD071B-035-KG1-KN servo motor and its associated drive system.

Reviews

There are no reviews yet.