Product Overview

In the field of control and protection for high-speed rotating machinery, millisecond-level state sensing often determines whether equipment undergoes a safe shutdown or catastrophic failure. The WOODWARD 9907-164 is a critical sensing layer hardware born from this context – it is not an ordinary digital input (DI) card, but a high-integrity state acquisition module specifically designed for the Woodward MicroNet Plus platform. As the “nerve endings” of control systems for thousands of gas turbines, steam turbines, and compressor units worldwide, the core mission of the 9907-164 is to transmit discrete signals from field switches, relay contacts, or PLC outputs to the controller in a high-fidelity, low-latency manner, for interlocking judgments, sequence control, and fault diagnosis.

I have led several control system upgrade projects for combined cycle power plants, where the WOODWARD 9907-164 was deployed in critical circuits such as main fuel valve position feedback, lubrication oil pressure low alarm, and overspeed trip signals. Its independent opto-isolation design for each channel effectively prevents false triggers caused by ground potential differences or VFD interference – this is especially crucial in the modernization of older power plants. Another major value of the WOODWARD 9907-164 lies in its deep integration with the MicroNet control logic: when a channel experiences an open circuit or short circuit, the system not only records the fault but can also precisely locate the specific terminal number on the HMI, significantly shortening troubleshooting time. This “diagnosability” is a core requirement of modern industry for I/O modules, far exceeding simple on/off detection. Technical Specifications

Product Model: 9907-164

Manufacturer: Woodward, Inc.

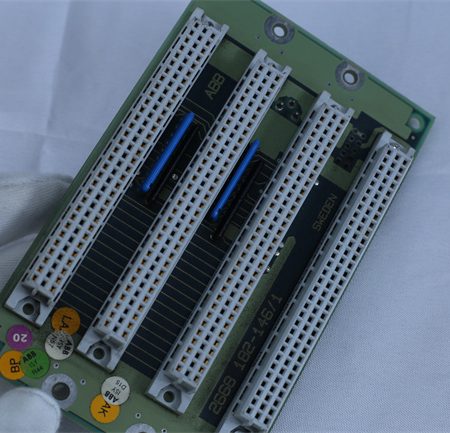

Product Type: 16-Channel Digital Input (DI) Module

Input Type: 24 V DC Wet Contact or Dry Contact (Internal isolated power supply provided)

Rated Input Voltage: 24 V DC (Range: 18–30 V DC)

Input Current: Typical 4 mA (@24 V DC)

Channel Isolation: Optocoupler isolation, >1500 V RMS (Channel to backplane)

Response Time: <5 ms (ON to OFF / OFF to ON)

Operating Temperature: -20°C to +70°C

Mounting Method: DIN rail, compatible with MicroNet Plus standard rack

Communication Interface: Dedicated high-speed serial backplane bus (MicroNet Plus)

Diagnostic Functions: Open circuit/short circuit detection per channel, status LED indicator

Protection Class: IP20 (Suitable for installation in control cabinets)

Key Features and Benefits

The design philosophy of the WOODWARD 9907-164 embodies an extreme pursuit of “state signal reliability.” In turbomachinery applications, a false “lubricating oil pressure normal” signal can lead to bearing failure; a delayed “overspeed” signal can cause rotor rupture. Therefore, this module eliminates such risks from its underlying architecture. Its independent isolated power supply and optocoupler design for each channel ensure that a single point of failure (such as a short circuit in the field) will not affect other channels, nor will it cause the entire module to fail – something many low-cost DI modules cannot achieve.

16-channel high-density layout saves cabinet space and reduces system costs.

Built-in channel-level diagnostics support remote identification of common problems such as loose wiring and sensor failure.

Wide voltage input range (18–30 V DC) adapts to varying field power supply fluctuations.

Seamless integration with Woodward ToolKit software, supporting online forcing, status monitoring, and historical data logging.

Optimized for the dynamic operating conditions of rotating machinery, with excellent resistance to electrical noise (EMI/RFI).

Reviews

There are no reviews yet.