Product Overview

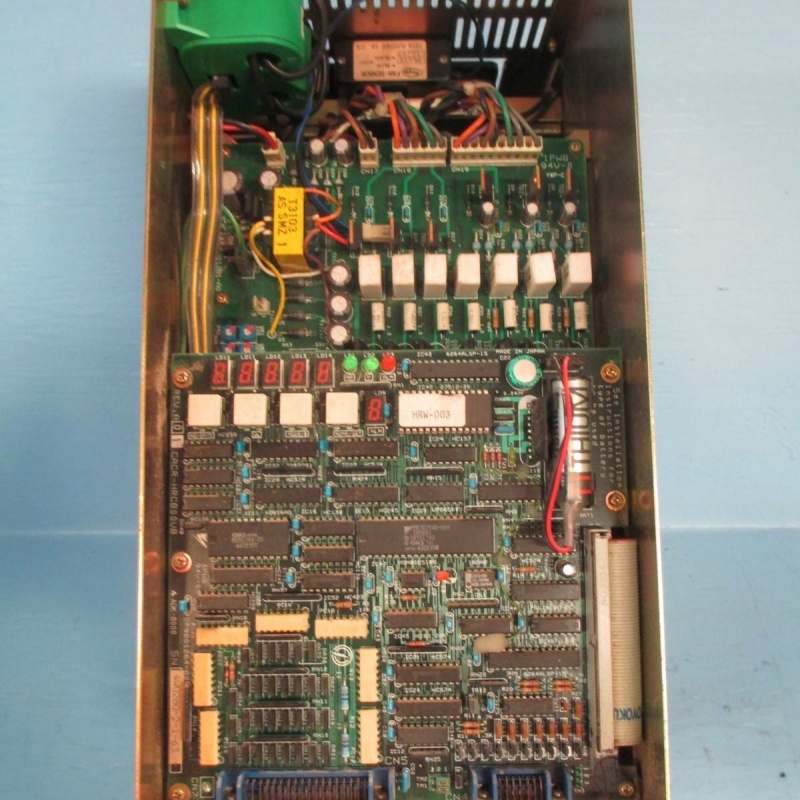

Yaskawa CACR-HR20UB ServoPack(often shortened to CACR-HR20)is a robust 2kW servo drive from Yaskawa’s HR series,engineered to handle medium to heavy industrial loads with precision.As a core component in automation systems,it acts as the”power translator,”converting control signals from PLCs or motion controllers into smooth,accurate motor movement—critical for applications where speed,torque,and positioning directly impact productivity.

Yaskawa CACR-HR20UB stands out for its balance of high power(2kW)and refined control,making it suitable for both continuous-operation machinery and dynamic motion tasks.Whether driving a robotic arm in an automotive plant or regulating a conveyor in a logistics hub,CACR-HR20 ensures consistent performance,even under fluctuating loads.Its design reflects Yaskawa’s expertise in servo technology,combining durable hardware with advanced algorithms to meet the demands of modern manufacturing and processing environments.

Technical Specifications

Parameter Name Parameter Value

Product Model Yaskawa CACR-HR20UB ServoPack(CACR-HR20)

Manufacturer Yaskawa(Yaskawa Electric Corporation)

Product Type AC Servo Drive(ServoPack)

Rated Output Power 2kW

Input Voltage 3-phase 200-240V AC,50/60Hz

Rated Output Current 10A(rms)

Control Modes Position control,speed control,torque control

Communication Interface Pulse train,analog input(0-10V/4-20mA),RS-485(Modbus)

Response Frequency 4kHz

Operating Temperature 0°C to 55°C

Storage Temperature-20°C to 65°C

Dimensions(W×H×D)120mm×180mm×150mm

Weight Approximately 2.5kg

Protection Features Overcurrent,overvoltage,undervoltage,overload,overheating,encoder fault,short-circuit

Installation Method DIN rail or panel mounting

Main Features and Advantages

2kW power with precision:Yaskawa CACR-HR20UB ServoPack delivers 2kW of steady power,making it ideal for medium-load tasks like driving conveyor belts in warehouses or rotating tables in machining centers.What sets it apart is its ability to maintain±0.1%speed stability even when load changes by 50%—critical for applications like bottle filling,where uneven speed causes overfilling or underfilling.

Fast response for dynamic tasks:With a 4kHz response frequency,CACR-HR20 reacts to control signals in milliseconds.In robotic pick-and-place operations,this means the arm can accelerate,decelerate,and stop sharply without overshooting,reducing cycle times by up to 15%compared to slower drives.

Rugged for tough environments:Built to withstand industrial rigors,Yaskawa CACR-HR20UB operates reliably in 0-55°C temperatures and resists vibration up to 5g.In metalworking shops—where coolant mist and dust are common—its sealed terminals prevent corrosion,extending service life to an average of 8+years in field tests.

Flexible integration:It plays well with Yaskawa’s SGMGH series 2kW motors,but also works with third-party motors via parameter tweaks.This flexibility shines during retrofits—an auto parts manufacturer recently upgraded their aging line by swapping in CACR-HR20,keeping existing motors and cutting upgrade costs by 30%.

Application Field

In automotive manufacturing,Yaskawa CACR-HR20UB ServoPack powers robotic welding arms,where its 2kW output and precise torque control ensure consistent weld penetration.The 4kHz response lets the arm adjust instantly to sheet metal thickness variations,reducing rework rates.It’s also used in chassis assembly lines,driving the rotation of worktables to position car frames for drilling—accuracy here prevents misaligned holes that would delay final assembly.

Logistics and material handling rely on CACR-HR20 for conveyor systems in distribution centers.It regulates belt speed to match upstream/downstream equipment,preventing bottlenecks.When paired with vision systems,it can even slow or stop sections to correct package misalignment,keeping sorting lines running smoothly during peak hours.

Plastic injection molding machines use Yaskawa CACR-HR20UB to control screw rotation,a critical step in melting and injecting plastic.Its torque control mode ensures consistent pressure on the molten plastic,reducing part defects like sink marks or flash—a major win for manufacturers of precision plastic components.

Related Products

Yaskawa CACR-HR10UB:A 1kW sibling of CACR-HR20UB,perfect for lighter loads like small pumps or label applicators.

Yaskawa CACR-HR30UB:A 3kW upgrade for heavier tasks(e.g.,large robotic arms)where CACR-HR20’s 2kW isn’t enough.

Yaskawa SGMGH-20DCA61:A 2kW servo motor,the”perfect partner”for Yaskawa CACR-HR20UB—pre-calibrated for plug-and-play performance.

Yaskawa JUSP-OP07A:A 5m shielded cable for connecting CACR-HR20 to motors,reducing electromagnetic interference in noisy factories.

Yaskawa SigmaWin+Software:Used to tune Yaskawa CACR-HR20UB parameters,optimizing speed,acceleration,and torque for specific tasks.

Installation and Maintenance

Pre-installation preparation:Mount Yaskawa CACR-HR20UB ServoPack on a DIN rail or panel with at least 100mm clearance above/below for airflow—overheating is the#1 cause of early failure.Check input voltage is 3-phase 200-240V;use a multimeter to confirm no voltage spikes.Connect motor and encoder cables to the correct terminals(color-coded in the manual)to avoid reversed rotation—swap two motor wires if the motor runs backward.

Maintenance recommendations:Inspect CACR-HR20 monthly for dust buildup;use compressed air to clean vents.Every 6 months,tighten terminal screws—vibration can loosen them,causing intermittent faults.Monitor the drive’s LED:green means all’s well,red indicates issues(check the manual’s fault code list—most are fixable via parameter resets).If the drive shuts down due to overload,let it cool 30 minutes before restarting;repeated overloads mean the drive is undersized for the task.

Product Guarantee

Yaskawa CACR-HR20UB ServoPack(CACR-HR20)comes with a 12-month warranty covering defects in materials and workmanship.Our technical team provides free phone/email support for installation,parameter tuning,and troubleshooting—we’ve helped dozens of clients resolve issues in under an hour.If the drive fails under normal use,we’ll repair or replace it promptly.We stand behind Yaskawa CACR-HR20UB’s reliability,backed by Yaskawa’s 100+years of servo expertise,ensuring it becomes a long-term asset in your automation setup.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953 SOLEMN COMMITMENT 1. For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay. 2. For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems. 3. For discontinued materials and equipment, we provide alternative models and equipment replacement process services. 4. For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free. 5. We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems. 6. Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour. 7. For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer. The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers. We supply directly from abroad, without middlemen, reducing the cost of use. There is really no middleman who can make a price difference! ! If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time. Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit. Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields! ABB 5SHY3545L0010/3BHB013088R0001 MOTOROLA MVME2434 MOTOROLA MVME2432 A-B 81001-450-53-R ABB PNI800 WOODWARD 9907-164 NI PXIE-4145 ABB CI871K01 3BSE056797R1 MOTOROLA MVME5500-0161 MOTOROLA MVME5500-0163 EMERSON MVME55006E-0163 GE DS200DCFBG1BJB ABB PPD113B01-10-150000 ABB PM904F 3BDH001002R0001 MOTOROLA MVME2400 FOXBORO H92A0K9V0H00 PIONEER MAGNETICS PM36218B-10P-1-8PH-J GE IC698CPE040-JP EMERSON MVME7100 ABB HPC800K02 ABB SYN5202-0277 ABB HPC800K02(含HC800模块、CP800模块、底座) MOTOROLA MVME5500 MOTOROLA MVME55006E-0163R GE IS215UCVEM09B AMAT 0090-76110 VME PCB ABB 5SHX2645L0002/3HB012961R0001 ABB AO2000-LS25 ABB PM865K01 3BSE031151R1 ABB 5SHX1445H0001 3BHL000391P0101 3BHB003230R0101 5SXE05-0152 KONGSBERG DPS112 GE VMIVME-7750 ABB AO2000-LS25 TRICON 4352B ABB PFSK152 TRICONEX 3009 MOOG D136-001-007 SCANde INTELLISCANDE14-405NM SCANLAB

Reviews

There are no reviews yet.