Application Scenarios

Application Scenarios

At a major copper mine in Chile,a critical SAG mill drive repeatedly tripped due to unexplained IGBT failures.Engineers traced the root cause to inconsistent gate drive signals and delayed fault feedback in the existing control architecture.After upgrading to the 3BHE047217R0101 GD D360 C gate drive boards across the ACS 8000 system,the drive achieved stable operation for over 18 months without a single IGBT fault.The 3BHE047217R0101’s fast DESAT detection and negative turn-off capability proved essential in protecting the power stack during voltage transients and load surges,directly reducing unplanned downtime and saving over$2M annually in maintenance and lost production.

Parameter

Parameter Value/Description

Product Model 3BHE047217R0101

Manufacturer ABB

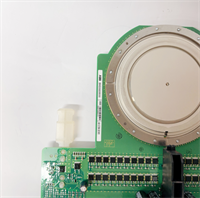

Product Category High Voltage Gate Drive Board

Series/Code GD D360 C

Primary Function IGBT Gate Driving&Fault Protection

Isolation Technology Optical Coupling(HVD-High Voltage Isolation)

Drive Voltage+15V(Turn-On),-8V(Turn-Off)

Fault Detection DESAT(De-saturation),Overcurrent,Short Circuit

Feedback Speed<2μs(DESAT response time)

Input Signal Low-voltage PWM from INT/RDCU board

Output Load IGBT Module Gate(G),Emitter(E),Collector(C)

Operating Temp(Surface)-20°C to+80°C

Installation Method Screw-mounted near IGBT stack

Compliance IEC 61800-5-1,UL,CE,EMC Standards

Technical Principles and Innovative Values

Innovation Point 1:High-Voltage Isolation(HVD)

The 3BHE047217R0101 employs advanced optical isolation technology to safely separate the 3.3kV–6.6kV DC bus from the low-voltage control system.This HVD design prevents noise coupling and ensures operator safety,even during transient overvoltages.

Innovation Point 2:Microsecond-Level Fault Response

Integrated DESAT circuitry detects IGBT overcurrent conditions in under 2 microseconds,triggering immediate shutdown.This ultra-fast response is critical for preventing catastrophic IGBT explosions in high-energy systems.

Innovation Point 3:Negative Voltage Turn-Off(-8V)

Unlike basic drivers,the 3BHE047217R0101 applies a-8V bias during turn-off,actively suppressing false triggering caused by high dV/dt transients—a common failure mode in high-power inverters.

Innovation Point 4:Modular&Redundant Design

Each 3BHE047217R0101 board typically drives one IGBT phase leg,enabling modular replacement.This design reduces maintenance time from hours to minutes,maximizing system uptime.

Application Cases and Industry Value

In a 500MW combined-cycle power plant in Germany,the boiler feedwater pump drives experienced frequent trips due to gate driver instability.The plant’s engineering team replaced legacy gate boards with the 3BHE047217R0101 GD D360 C across all ACS 6000 units.Post-upgrade,the Mean Time Between Failures(MTBF)for the drives increased from 14 months to over 4 years.Operators reported zero IGBT-related failures in the first two years,directly contributing to a 99.8%plant availability rate.The 3BHE047217R0101’s consistent signal integrity and thermal resilience under continuous load were key to this success.

Related Product Combination Solutions

3BHE034863R0001 UDC920 BE01:ABB’s main control unit that generates PWM signals sent to the 3BHE047217R0101,forming the control core of the drive system.

INT-xx Series Boards:Interface modules that condition and route signals between the UDC and 3BHE047217R0101,ensuring signal integrity.

RDCU-xx Modules:Drive communication units that provide synchronization and diagnostics to the 3BHE047217R0101 via fiber or bus links.

3BHE036348R0103 XZC826A103:Power unit housing the IGBT modules driven by the 3BHE047217R0101,completing the power conversion chain.

3BHE047217R0102:Potential alternate version or revision of the same gate drive platform,used in different drive configurations.

ABB ACS 8000 Frame:The complete medium-voltage drive cabinet where the 3BHE047217R0101 is installed,designed for 3.3kV to 6.6kV applications.

Drive Power Supply Units:Dedicated+15V/-8V isolated power supplies that ensure stable operation of the 3BHE047217R0101 under load fluctuations.

Bently Nevada 3500 System:Often used alongside ABB drives for vibration monitoring;integration enhances predictive maintenance when paired with 3BHE047217R0101-driven systems.

Installation,Maintenance,and Full-Cycle Support

Proper installation of the 3BHE047217R0101 begins with complete system de-energization and verification of DC bus voltage below 50V.Technicians must use ESD-safe tools and follow torque specifications when mounting the board near the IGBT stack.Connection to the control and power circuits should use shielded cables,with attention to minimizing loop area to reduce EMI.After installation,a low-voltage functional test is recommended before full energization.

Routine maintenance includes visual inspection for discoloration,capacitor swelling,or dust accumulation,especially in high-humidity environments.The 3BHE047217R0101’s modular design allows for rapid replacement in under 30 minutes,minimizing production impact.Our global support network provides 24/7 technical assistance,firmware updates,and lifecycle management for ABB drive components.We offer calibration,testing,and repair services to extend the operational life of the 3BHE047217R0101,ensuring long-term reliability and cost-effective asset management.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.