Application Scenarios

At a natural gas compressor station in Texas, maintenance teams struggled with extended outages during I/O module replacements due to hardwired legacy systems. After upgrading to ABB’s S800 I/O architecture using 3ASC25H216A DATX132 bases paired with 3BHE024577R0101 electronics, they achieved true hot-swap capability. When a lightning surge damaged one DI module, technicians replaced it in under 3 minutes—without shutting down the compressor. The clearly labeled screw terminals and per-bank LEDs reduced wiring errors by 90%, and the system passed API 1164 cybersecurity audits thanks to secure, segregated I/O design.

Technical Principles and Innovative Values

Innovation Point 1: The DATX132 enables tool-free hot swapping—the electronic module can be replaced while the system is live, with the base maintaining field wiring integrity and backplane isolation.

Innovation Point 2: Its modular separation of field wiring (base) and electronics (cartridge) drastically reduces spare parts inventory—only the failed electronics need replacement, not the entire wired assembly.

Innovation Point 3: Color-coded terminal blocks and grouped LEDs allow rapid visual verification during commissioning and troubleshooting, cutting startup time by up to 40%.

Innovation Point 4: The base includes mechanical keying to prevent incorrect insertion of incompatible electronic modules (e.g., DO into DI slot), enhancing safety and reliability.

Application Cases and Industry Value

In a pulp & paper mill in Finland, over 200 DATX132 (3ASC25H216A) bases were installed across dryer sections to monitor steam valve positions and belt break sensors. During a scheduled maintenance window, engineers replaced 12 faulty DI cartridges in under an hour—previously, this would have required de-energizing entire sections and re-terminating hundreds of wires. The plant now achieves 99.8% control system availability and has eliminated I/O-related production delays.

Another case involved a water treatment plant in Australia adopting System 800xA for SCADA modernization. The DATX132’s clear labeling and standardized layout allowed local contractors—unfamiliar with ABB systems—to correctly wire 150+ I/O points on the first attempt, avoiding costly rework.

Related Product Combination Solutions

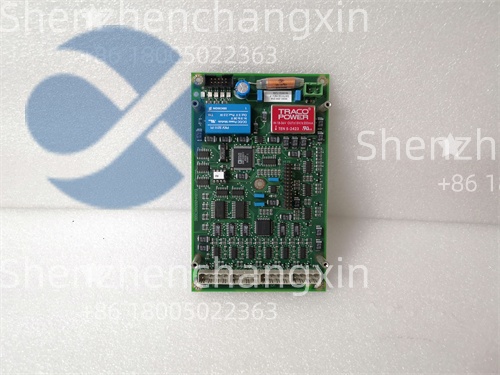

ABB 3BHE024577R0101: 32-channel DI electronic module that plugs into DATX132

ABB TB840A: Alternative terminal base for non-S800 I/O (legacy AC 800M)

ABB 3BSE069298R1: AC 800M CPU (PM866) that communicates with S800 I/O via CI854/CI874

ABB CI854A: Profibus DP communication interface for S800 I/O racks

ABB CI874: PROFINET/IEC 61850 communication module for S800 I/O

ABB DATX131: 16-channel version of the same terminal base family

ABB DAXX132: Digital output terminal base counterpart (for DO modules)

ABB 3BHE037864R0106: System 800xA engineering server for configuration

Installation, Maintenance, and Full-Cycle Support

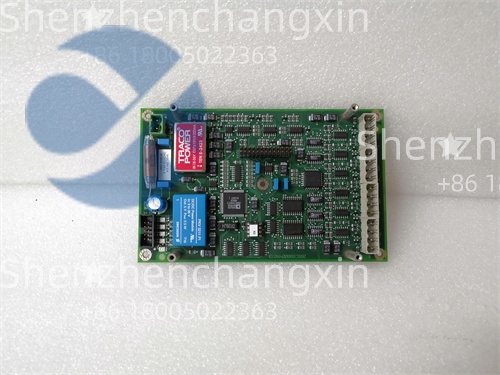

Installation of the 3ASC25H216A DATX132 involves:

Mounting the base on a DIN rail

Wiring field devices to screw terminals (clearly labeled 1–32)

Plugging in the compatible electronic module (e.g., 3BHE024577R0101) until it clicks

No tools are needed for module insertion/removal. The base remains permanently wired, enabling future upgrades without rewiring.

Maintenance is simplified by:

Group LEDs indicating channel status

Replaceable electronics without disturbing field wiring

Diagnostic data accessible via Control Builder M or Asset Optimization tools

We supply genuine ABB 3ASC25H216A DATX132 terminal bases—brand new, factory sealed, with full traceability and compliance documentation. Each unit is tested for terminal torque integrity, insulation resistance, and mechanical retention force. Our offering includes a 24-month warranty, free wiring templates, and expert support for S800 I/O system design.

Reviews

There are no reviews yet.