Application Scenarios

At a municipal wastewater treatment plant in Germany, over 200 pump run-status and valve position signals needed centralized monitoring. Space in the control cabinet was limited, and budget constraints ruled out redundant I/O. Engineers selected ABB AC 800M controllers paired with DI04 modules—each handling 32 inputs in a single slot. The system integrated seamlessly into System 800xA, providing real-time HMI visibility and alarm logging. During a lightning storm, induced transients caused false signals on several lines—but the DI04’s built-in filtering and 5 ms debounce prevented spurious alarms. Over five years, zero DI04 modules failed. The DI04 delivered enterprise-grade reliability at a fraction of the cost of premium I/O.

Technical Principles and Innovative Values

Innovation Point 1: High Channel Density in Standard Form Factor

32 inputs in a single module reduce rack space, wiring complexity, and overall system cost—ideal for large-scale discrete monitoring.

Innovation Point 2: Flexible Field Wiring

Supports both PNP and NPN sensors through terminal configuration, eliminating the need for interface relays in mixed-vendor plants.

Innovation Point 3: Seamless 800xA Integration

Auto-detected in Control Builder M, with tag data flowing directly to System 800xA graphics, trends, and alarm journals.

Innovation Point 4: Built-In Diagnostics

Detects open circuits (e.g., broken wire or de-energized sensor) and reports faults via the CPU—enabling predictive maintenance.

Application Cases and Industry Value

A paper mill in Finland retrofitted its stock preparation area with ABB AC 800M and DI04 modules to replace aging relay logic. With 192 discrete signals (conveyors, level switches, door interlocks), they used just six DI04 cards. Commissioning took three days instead of three weeks. Within one year, unplanned stops due to “mystery” sensor failures dropped by 70%—thanks to the DI04’s open-circuit diagnostics alerting maintenance before failures cascaded. The ROI was achieved in under 14 months. The DI04 proved that smart, simple I/O can drive major operational gains.

Related Product Combination Solutions

Baseplate: TB820 (single-slot I/O carrier)

Terminal Units: TU830 (screw), TU831 (spring-cage)

Controller: AC 800M PM864

Complementary I/O:

DO04 (32-channel digital output)

AI04 (analog input)

AO04 (analog output)

Engineering Software: Control Builder M, System 800xA

Power Supply: TK811K (24 V DC for I/O)

Communication: CI854 (Modbus/Profibus gateway)

Installation, Maintenance, and Full-Cycle Support

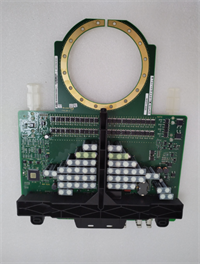

The DI04 installs onto an ABB TB820 baseplate, which mounts on a DIN rail. A TU830 or TU831 terminal block snaps onto the front for field wiring. Configuration is performed in Control Builder M, where input tags, filtering, and alarm behaviors are defined.

Maintenance is simplified by:

Per-channel LEDs for instant visual verification

Open-circuit diagnostics reported to the CPU

Robust design with conformal coating options for humid/dusty areas

We fully test every DI04 (3BSE008576R1) for:

Channel-by-channel input response accuracy

Isolation integrity (500 V test)

Communication handshake with AC 800M

LED functionality and fault reporting

All units include calibration/test reports and are verified against ABB OEM specifications.

Contact us for expert support—whether you need a single DI04 replacement, bulk procurement for a retrofit project, or integration guidance for System 800xA. We also provide firmware compatibility checks, wiring diagrams, and lifecycle management for legacy ABB I/O systems worldwide.

Reviews

There are no reviews yet.