Application Scenarios

At an automotive body shop in Germany, a fleet of ABB IRB 6640 spot-welding robots experienced intermittent “position loss” errors during high-current welding cycles. Diagnostics traced the issue to noise-induced corruption in incremental encoder signals. After upgrading to absolute encoders paired with 3HNA023093-001 interface modules, the robots achieved:

Zero homing time at startup (critical for 24/7 production)

Immunity to 100 kA welding transients due to the module’s optical isolation and differential signaling

Full multi-turn position retention during brief power interruptions

Over 18 months, unplanned downtime dropped by 72%, and weld seam quality improved due to consistent TCP (Tool Center Point) repeatability within ±0.02 mm.

Key Parameters

Technical Principles and Innovative Values

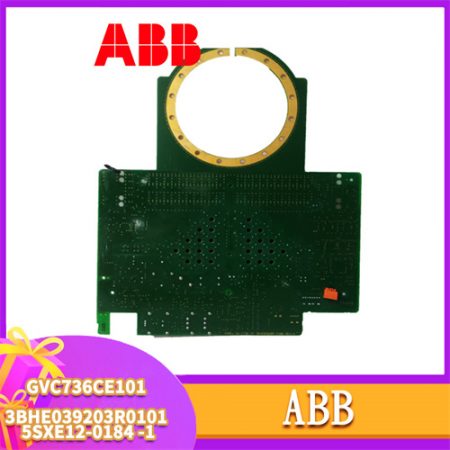

Innovation Point 1: Protocol-Agnostic Firmware Architecture – The 3HNA023093-001 uses reconfigurable FPGA logic to support multiple absolute encoder protocols without hardware changes. A simple software parameter in RobotStudio selects SSI, BiSS-C, or EnDat—simplifying spare parts management across robot models.

Innovation Point 2: Real-Time Integrity Monitoring – Unlike basic decoders, this module continuously validates encoder data using embedded CRC checks and monitors signal symmetry. If noise distorts the clock/data timing beyond tolerance, it triggers a controlled axis stop—not a catastrophic crash.

Innovation Point 3: Power-Fail Position Memory – In conjunction with multi-turn encoders, the 3HNA023093-001 enables “absolute after power-off” functionality. Robots resume operation instantly after outages—eliminating time-consuming homing routines that cost automotive lines up to €15.000/hour in lost throughput.

Typical Industry Applications

Automotive Manufacturing: Spot welding, hemming, paint application with IRB 6600/6700 series

Electronics Assembly: High-precision SCARA and 6-axis robots requiring sub-millimeter accuracy

Metal Casting: Foundry robots operating near molten metal, where encoder reliability is life-critical

Palletizing & Packaging: High-cycle Delta or 4-axis robots needing fast, repeatable positioning

Research & Lab Automation: Collaborative cells requiring certified position feedback for safety zones

Related Product Combination Solutions

DSQC668 / DSQC1030: ABB drive modules that receive position data from 3HNA023093-001 for servo control

IRB 6700 / IRB 7600: Industrial robots commonly retrofitted with this encoder interface during upgrades

OmniCore Controller: Next-gen ABB platform where 3HNA023093-001 enables advanced motion features

Heidenhain ECN 1100 / Baumer HOG 10: Absolute encoders frequently paired with this module

RobotStudio: ABB’s offline programming suite used to configure encoder type and resolution

3HNA023094-001: Companion module for incremental encoder inputs (complementary product)

Battery Backup Units (e.g., 3HAC028317-001): Preserve multi-turn counts during extended outages

Installation, Maintenance & Lifecycle Support

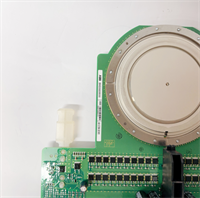

Installation must be performed by ABB-certified technicians inside the robot controller cabinet. The 3HNA023093-001 connects via shielded twisted-pair cables to each joint’s encoder, with shields grounded at the controller end only. Configuration is done through RobotStudio or the FlexPendant service port.

Maintenance includes:

Verifying encoder signal integrity using ABB’s Service Tool diagnostics

Checking for “Position Error” or “Feedback Loss” logs in event history

Replacing only if CRC error rates exceed thresholds or mechanical damage occurs

Reviews

There are no reviews yet.