Application Scenarios

On a high-speed automotive assembly line, a massive IRB 6640 robot performs precise spot welding on a car body frame. Every complex movement of its powerful arm—its reach, its acceleration, its pinpoint stop at the weld point—is governed by a symphony of control. The ABB DSTD150 is a key player in this orchestra. Each major axis of the robot is typically managed by its own DSTD150 module. This module receives the trajectory command from the main controller and, in real-time, calculates the exact power needed for the servo motor, while constantly monitoring feedback from the motor’s resolver. It ensures the 100kg arm moves with millimeter precision at speeds of over two meters per second. For the maintenance team, a fault in a DSTD150 doesn’t just mean an error code; it means a halted production line costing tens of thousands per hour. This module is the crucial link that turns intelligent path planning into physical, productive motion.

Key Parameters

Technical Principles and Innovative Values

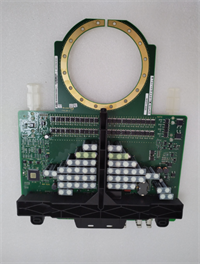

The ABB DSTD150 is more than a simple amplifier; it is a decentralized, intelligent motion controller that embodies ABB’s distributed control philosophy for robotics.

Innovation Point 1: Distributed “Axis Computer” Architecture. Unlike centralized drives, the DSTD150 embeds significant processing power locally. Each module acts as an independent “axis computer,” handling the demanding real-time calculations for its specific motor’s current, speed, and position loops. This offloads the main controller, allowing it to focus on advanced path planning and coordination, resulting in smoother, faster, and more computationally efficient robot motion, which is critical for high-speed applications like packaging or arc welding.

Innovation Point 2: Integrated Safety and Advanced Diagnostics. The module is deeply integrated with ABB’s SafeMove safety system. It continuously monitors torque, speed, and position, enabling software-configured safety zones and limits without additional hardware. Furthermore, it provides granular diagnostic data—from IGBT temperature and DC-link voltage to detailed error histories. This allows predictive maintenance, such as anticipating cooling fan failure or detecting degrading motor performance, preventing catastrophic stops.

Innovation Point 3: Optimized Power Density and Regenerative Handling. Designed for the high dynamic demands of robotics, the DSTD150 features a compact, high-power-density design. It efficiently manages the regenerative energy produced when the massive robot arm decelerates, channeling it back to the DC link for use by other axes or dissipating it safely. This reduces overall energy consumption and heat generation within the controller cabinet, enhancing system reliability.

Application Cases and Industry Value

Case Study: Maximizing Uptime in a Foundry Casting Cell

A foundry using an IRB 6600 robot for precise pouring of molten metal experienced unscheduled downtime. The robot would fault intermittently with a “Drive System” error, causing incomplete pours and costly material waste. Diagnostics pointed to an inconsistency in the axis 3 drive chain.

Technicians used the robot’s built-in service information to analyze the logs from the suspect DSTD150 module. The data revealed a pattern of subtle, brief over-current events during specific arm movements, not severe enough to cause an immediate hard stop but indicative of a developing issue. This advanced warning allowed the maintenance team to schedule a repair during a planned furnace reline. They replaced the aging DSTD150 module and inspected the associated motor and caballing. The proactive replacement, guided by the module’s own diagnostics, restored perfect motion and prevented what would have likely been a sudden, production-halting failure during peak operation. The foundry engineer credited the detailed diagnostic capability of the DSTD150 with saving an estimated 48 hours of lost production.

Related Product Combination Solutions

The DSTD150 operates within a tightly integrated ecosystem inside the IRC5 controller. Key related components include:

DSQCxxxx (e.g., DSQC 1000): The main computer/controller module (Main Computer Board) that runs the robot software and sends motion commands to the DSTD150 drive modules.

Other DSTD Modules (e.g., DSTD145. DSTD175): Drive modules for different power ranges or for controlling different robot models (like smaller or larger arms), used together in a multi-axis system.

DSQC 1030 / DSQC 1015: I/O modules that handle communication with peripheral equipment (conveyors, grippers, welders), synchronized with motion controlled by the DSTD150.

Drive Communication Link Cables: Specialized, high-integrity cables that carry data and power between the main computer, drive modules, and motors.

Servo Motor (e.g., M2000/M4000 series): The motor on the robot arm that is directly driven and controlled by the DSTD150. The module is specifically tuned for these motors.

Resolver Cable & Feedback Unit: The critical feedback cable that connects the motor’s resolver to the DSTD150. completing the closed-loop control.

Power Supply Unit (PSU): Provides the main DC link power to the bank of DSTD150 drive modules within the cabinet.

Installation, Maintenance, and Full-Cycle Support

WARNING: Installation and handling of the ABB DSTD150 involve high voltage and precise mechanical alignment. This must be performed by certified ABB robot technicians following strict safety procedures and using the correct tools.

Installation is a systematic process within the IRC5 cabinet. It requires powering down and locking out the controller, carefully removing the old module, and seating the new DSTD150 firmly into its guided slots and connectors. Correct torque settings on electrical connectors are critical. After physical installation, the robot system must be powered on, and the new module’s parameters must be loaded, often via a dedicated service USB stick or from the system backup. A full calibration of the affected robot axis is then mandatory to ensure optimal performance.

Routine maintenance involves keeping the controller cabinet clean and ensuring cooling fans are operational. The primary “maintenance” activity is monitoring the drive’s performance and error logs through RobotStudio or the FlexPendant. We provide comprehensive support for the DSTD150. from initial identification and sourcing of guaranteed authentic or certified refurbished modules to technical consultation. We can also assist with accessing necessary documentation and calibration procedures to ensure a successful repair, minimizing costly robot downtime.

Minimize robot downtime with reliable drive components. Contact us for the genuine ABB DSTD150 and expert support for your IRC5 robotic system.

Reviews

There are no reviews yet.