Application Scenarios:

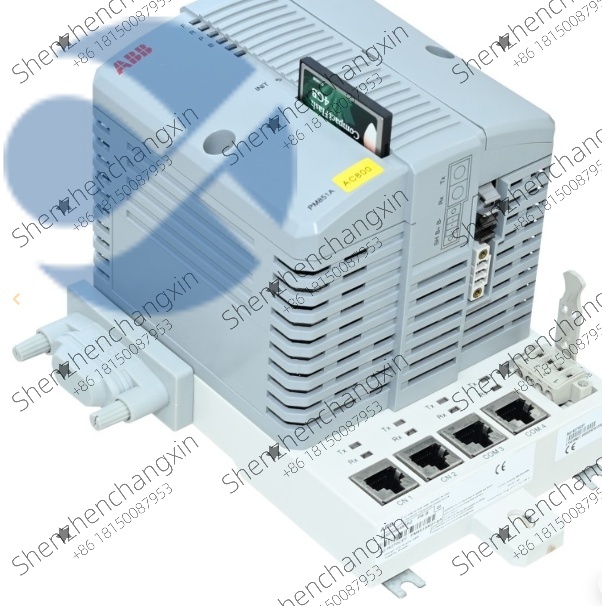

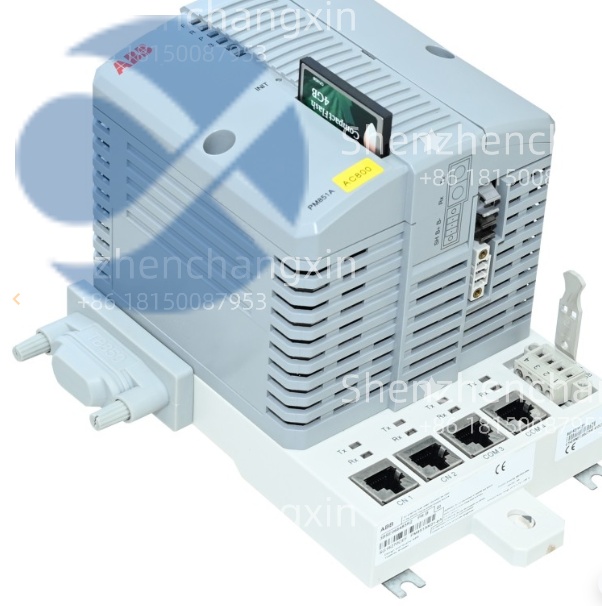

In a large-scale chemical processing plant, a continuous catalytic cracking unit requires precise control of temperature, pressure, and flow rates across hundreds of loops. Any controller failure could lead to a runaway reaction, unsafe conditions, and millions in lost production. The ABB 3BHE009681R0101 (GVC750BE101) controller module is deployed in a redundant (hot-standby) configuration within an AC 800M rack. It executes advanced regulatory and sequential control algorithms with millisecond precision. Its high-speed communication links gather data from remote I/O stations and exchange information with other controllers and the operator station. If a fault is detected in the primary CPU, the redundant partner takes over control within a single scan cycle, ensuring uninterrupted and safe operation. It solves the paramount challenges of ultra-high availability, deterministic control, and operational safety in mission-critical continuous processes.

Parameter:

Technical Principles and Innovative Values:

Innovation Point 1: Unified Control Architecture for Process & Safety. The AC 800M platform, represented by modules like the GVC750BE101. pioneered a unified controller capable of handling both standard process control (PLC/DCS) and critical safety functions (SIS) within a single hardware platform. This eliminates the need for separate safety controllers in many cases, reducing complexity, lifecycle costs, and engineering effort while ensuring seamless data exchange between control and safety systems.

Innovation Point 2: Deterministic, High-Performance Execution Engine. At its core, the module employs a powerful, optimized real-time operating system and processor. It provides deterministic, hard real-time performance essential for fast control loops (e.g., compressor anti-surge, turbine control). Its execution is predictable and repeatable, regardless of network load or programming complexity, which is non-negotiable for stable plant operation.

Innovation Point 3: Seamless Horizontal and Vertical Integration. The module is designed as a nexus for connectivity. Horizontally, it communicates with peer controllers and I/O at high speeds via dedicated networks like Controller Link and MB300. Vertically, it integrates seamlessly with the System 800xA operator environment and enterprise systems via standard Ethernet and OPC. This creates a cohesive information and control architecture from field device to management level.

Application Cases and Industry Value:

Case Study: Offshore Oil & Gas Platform Central Control System.

An offshore platform required a complete control system modernization to improve reliability and enable remote operations. The project was based on ABB Ability™ System 800xA with AC 800M controllers (3BHE009681R0101 / GVC750BE101) as the primary process controllers. They handled all process control on the platform, from separator level control to gas compression. Installed in redundant pairs, they provided 99.999% availability. The lead control engineer reported: “The AC 800M controllers were the workhorses. Their ability to run over 15.000 interconnected function blocks without breaking a sweat was impressive. The seamless failover during a simulated power glitch was flawless. More importantly, their tight integration with 800xA gave our operators a single, unified view of both process and safety, drastically improving situational awareness and response times.”

Case Study: Pulp & Paper Mill Distributed Control System.

A large pulp mill needed to replace its aging, multi-vendor control system with a unified, modern DCS to improve product consistency and yield. The heart of the new system was a network of over 20 AC 800M controllers, including the high-performance GVC750BE101 modules, distributed across the plant (digester, bleach plant, recovery boiler, paper machine). They controlled complex, interconnected processes with advanced regulatory and model predictive control (MPC) strategies. The project manager stated: “The processing power and communication speed of the AC 800M CPUs allowed us to implement truly distributed control with intense peer-to-peer communication. This reduced the load on the network and enabled faster closed-loop control. The result was a 5% reduction in chemical usage and a 2% increase in throughput due to much better process stability, paying back the investment in under 18 months.”

Related Product Combination Solutions:

System 800xA Extension Nodes / Operator Stations: The operator interface and engineering workstations that configure, monitor, and control the applications running on the AC 800M (GVC750BE101).

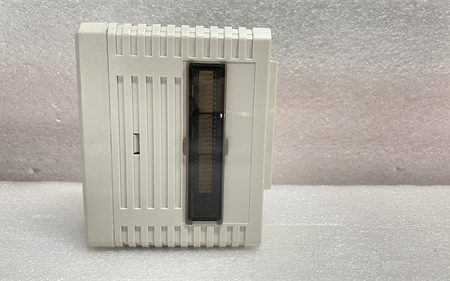

S800/S900 I/O System: ABB’s distributed I/O family (e.g., CI854 communication interface, AI810 analog input module) that connects field sensors and actuators to the AC 800M controller via the MB300 network.

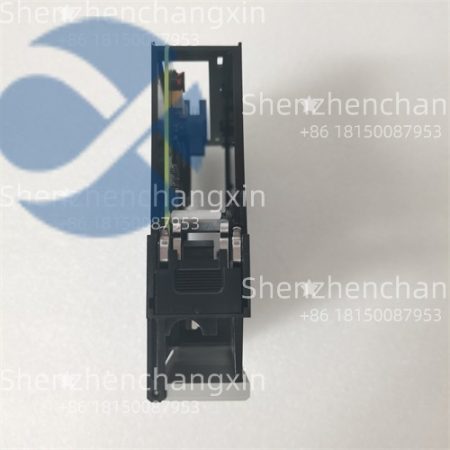

AC 800M Communication Modules: Companion modules like the CI854 (for Profibus, Foundation Fieldbus, etc.) or EI813 (Ethernet Interface) that expand the connectivity options of the main processor.

AC 800M Power Supply Units (e.g., SD822. SD823): The redundant, hot-swappable power supply modules that provide clean, reliable power to the controller rack and its modules.

AC 800M Base Units & Backplanes: The physical racks (e.g., PP815. PP836) that house the GVC750BE101 processor, power supplies, and communication modules.

Control Builder M Engineering Software: The primary engineering and configuration tool used to program the control application, configure hardware, and commission the AC 800M controller.

SIL2/SIL3 Certified Safety Modules: For applications requiring functional safety, dedicated safety I/O modules and safety-rated versions of the AC 800M controller (like PM861 safety controller) can be integrated.

Installation, Maintenance, and Full-Cycle Support:

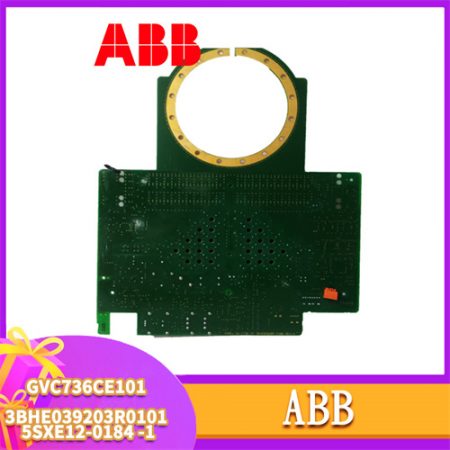

Installation is performed by qualified system integrators or ABB engineers. The GVC750BE101 module is carefully inserted into its designated slot in the AC 800M base unit. Proper grounding, power sequencing, and network cabling (following ABB’s strict guidelines) are critical. Configuration is done entirely in software using Control Builder M. The hardware is defined in the project, and the control application is downloaded to the controller.

Maintenance for such high-availability systems is largely predictive and online. Key tasks include monitoring controller health and diagnostics via System 800xA, performing periodic firmware updates (following detailed procedures), and having a tested, like-for-like spare module on hand. In a redundant configuration, the standby controller can be taken offline for maintenance without impacting the process. Common operational issues are typically related to application logic, network configuration, or I/O communication, which are diagnosed via the extensive diagnostic tools in Control Builder M and 800xA. Module replacement involves putting the controller in a safe state, powering down the rack (or removing the module in a hot-swap-supported rack), replacing the unit, and allowing the system to synchronize.

Important Note: The 3BHE009681R0101 (GVC750BE101) is a specific variant within the evolving AC 800M family. For new projects, consulting the latest ABB documentation and choosing the currently recommended processor (e.g., PM864T, PM865) is essential. For existing installations, this module is a critical spare part.

We can supply the genuine ABB 3BHE009681R0101 GVC750BE101 controller module. Our technical support can assist with compatibility verification, sourcing, and provide guidance for migration or integration within your System 800xA or other ABB DCS architecture.

Equip your mission-critical process with a proven, high-performance controller brain. Contact us for the genuine ABB AC 800M controller module and expert DCS support.

Reviews

There are no reviews yet.