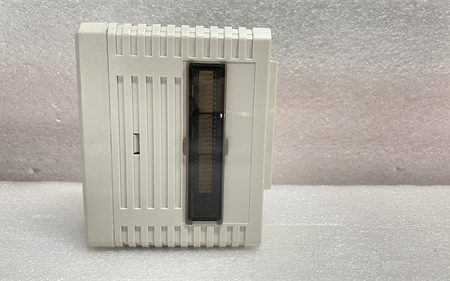

ABB PM902F 3BDH001000R0001 is a fail-safe, redundant programmable logic controller (PLC) module designed for the AC 900F distributed control system—ABB’s legacy yet widely deployed platform for process automation in power, water/wastewater, oil & gas, and industrial utilities. Engineered for high availability and continuous operation, the PM902F supports hot-swap redundant CPU configuration, ensuring zero downtime during hardware failures or maintenance—a critical requirement for 24/7 operations like boiler controls, turbine protection, or municipal water treatment.

At a major European district heating plant, an aging single-CPU system caused unscheduled outages during firmware updates and occasional memory faults. After upgrading to a dual PM902F 3BDH001000R0001 redundant setup, the facility achieved 99.999% operational availability over three years. During a live memory module failure in 2024. the standby CPU took over seamlessly within <50 ms, with no disruption to pump sequencing or temperature regulation—avoiding a potential service interruption affecting 200.000 residents.

Parameter

表格

Technical Principles and Innovative Values

True Hot-Standby Redundancy: In a dual PM902F configuration, the standby unit continuously mirrors the active CPU’s program state, I/O image, and internal variables. Upon failure detection (via heartbeat loss or self-test fault), switchover occurs in <50 ms—faster than most process dynamics—ensuring uninterrupted control.

Integrated Safety Capability: Certified to SIL 2. the PM902F can execute safety-related logic (e.g., emergency shutdown, boiler flame failure) alongside standard process control—eliminating the need for a separate safety PLC in mid-complexity applications.

Legacy Modernization Bridge: While newer plants use AC 800M, thousands of AC 900F systems remain in service. The PM902F enables life extension through improved reliability, while maintaining full compatibility with existing I/O modules (e.g., AI901F, DO901F).

Robust Communication Stack: Built-in support for Modbus RTU, Profibus DP, and ABB’s proprietary F-bus allows integration with third-party devices, HMIs, and SCADA systems without gateways.

Application Cases and Industry Value

In a U.S. wastewater treatment facility, PM902F 3BDH001000R0001 controllers manage aeration basin DO control, sludge recirculation, and chemical dosing across three redundant lines. Prior to upgrade, single-point CPU failures caused basin upset and permit violations. Post-upgrade, the plant has recorded zero process-related violations in 28 months, with engineers performing CPU replacements during normal shifts—no weekend outages required.

Another example: a Southeast Asian sugar mill uses PM902F to automate its batch crystallization process. The fast scan time and deterministic I/O handling ensure precise timing of vacuum release and seeding—boosting crystal yield by 4.2% compared to the previous relay-based system.

Related Product Combination Solutions

AC 900F Rack (e.g., CP900F): Chassis supporting redundant PM902F CPUs and mixed I/O modules.

AI901F / AO901F: Analog input/output modules commonly used with PM902F for process signals.

DI901F / DO901F: Digital I/O modules for motor control, valve feedback, and alarms.

CM904F Communication Module: Adds Ethernet/IP or Modbus TCP for modern SCADA integration.

Freelance Engineering Suite: Official ABB software for programming, commissioning, and diagnostics.

Power Supply Unit (PS902F): Redundant-capable 24 VDC supply for the AC 900F rack.

Operator Station (e.g., Freelance OS): HMI solution tightly integrated with PM902F logic.

Migration Path to AC 800M: For long-term strategy, ABB offers tools to port logic from Freelance (AC 900F) to Control Builder M (AC 800M).

Installation, Maintenance, and Full-Cycle Support

Installing PM902F 3BDH001000R0001 requires two units in a redundant rack configuration, connected via the dedicated sync bus. Configuration is performed in Freelance Engineering, where redundancy is enabled with a few clicks—no complex scripting needed. Both CPUs share the same project download; the system automatically handles state synchronization.

Maintenance benefits from hot-swap capability: a faulty CPU can be replaced while the system runs. Diagnostic LEDs indicate “Active,” “Standby,” “Fault,” or “Sync OK.” Comprehensive event logs are stored in non-volatile memory for post-failure analysis.

As an authorized supplier for Hitachi Energy (formerly ABB), we provide new surplus or factory-new PM902F 3BDH001000R0001 units with original packaging, test reports, and compatibility verification for existing AC 900F systems. Every unit undergoes functional testing—including redundancy switchover simulation and communication stress tests. Backed by a 12-month warranty and expert legacy-system support, we help you maximize uptime and defer costly full-platform migrations.

Contact us for spares, redundancy audits, firmware updates, or migration planning—ensuring your AC 900F system remains reliable, compliant, and operational well into the 2030s.

Reviews

There are no reviews yet.