Application Scenarios

In a large bottling plant, hundreds of sensors—from bottle presence detectors on the conveyor to cap-on-torque verification units and tank level switches—generate simple on/off (24V DC) signals. These signals are the digital “nervous system” of the plant, informing the control system of the process status. The ABB DI810 module is the critical component that gathers these signals. Installed in a decentralized I/O station near the production line, it connects to 16 of these sensors. Its robust design filters out electrical noise from large motors and variable-frequency drives, ensuring that a sensor’s “on” state is accurately read as a logic “1” by the controller. For maintenance technicians, the module’s per-channel LED status indicators allow for instant visual troubleshooting, turning a complex diagnostic task into a simple visual check. The DI810 reliably translates the physical state of the plant into actionable data for the control system, forming the foundation for automated sequencing and interlocking.

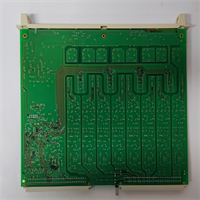

Key Parameters

Technical Principles and Innovative Values

The ABB DI810 is engineered for supreme reliability and serviceability in handling discrete signals, a deceptively simple task that is critical for system uptime.

Innovation Point 1: Advanced Input Filtering for Ultimate Noise Immunity. Industrial environments are electrically noisy. The DI810 incorporates sophisticated input filtering on each channel, designed to reject transient spikes and contact bounce that could cause false triggering. This filtering is hardware-based, ensuring stable signal recognition without the latency of software filtering, which is crucial for high-speed counting or fast interlock applications, guaranteeing that every sensor state change is captured accurately and only once.

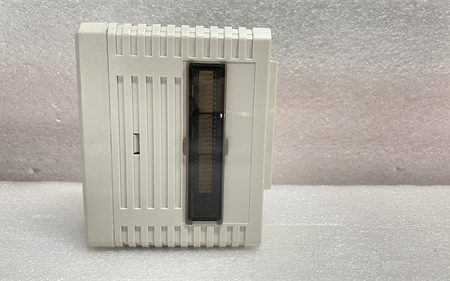

Innovation Point 2: Service-Optimized, Front-Accessible Design. The module features a removable, front-mounted terminal block. This allows all field wiring to be completed and checked beforethe electronic module is installed. In the event of a failure, a technician can swap the entire DI810 module in under 30 seconds without disturbing the field wiring, dramatically reducing Mean Time To Repair (MTTR). This design philosophy prioritizes operational uptime above all else.

Innovation Point 3: Comprehensive Diagnostics for Proactive Maintenance. Beyond a simple pass-through device, the DI810 provides clear, immediate diagnostic feedback. Each channel has a dedicated green LED that illuminates with a valid input signal. This allows for instant visual verification of sensor activity during commissioning and rapid fault localization during operation. Coupled with module health reporting to the control system, it enables a shift from reactive repair to proactive maintenance.

Application Cases and Industry Value

Case Study: Enhancing Reliability in a Wastewater Pumping Station

A city’s remote wastewater pumping station, operating with an older control system, suffered from frequent, unexplained pump stop/starts. The issue was traced to unreliable readings from float switches in the wet well. Electrical noise and corroded contacts caused the digital inputs on the existing PLC to “chatter,” confusing the control logic.

During an automation upgrade, the new system utilized S800 remote I/O with ABB DI810 modules to interface with all level and alarm switches. The robust channel isolation and built-in filtering of the DI810 completely eliminated the signal chatter. The per-channel LEDs allowed city maintenance staff to visually confirm the operation of each float switch during routine checks without needing a laptop. Over the following year, the number of nuisance alarms and pump sequencing errors dropped to zero. The water utility reported significantly reduced maintenance call-outs to the remote site and increased confidence in the automated system’s reliability, directly attributed to the stable signal acquisition provided by the DI810 modules.

Related Product Combination Solutions

The ABB DI810 operates as part of a modular S800 I/O station. A complete station for discrete control typically integrates it with:

DO810: The 16-channel digital outputcounterpart, used to command actuators like solenoid valves, contactors, and indicator lamps, forming a complete digital I/O pair.

AI810 / AI815: Analog input modules for reading 4-20mA signals from devices like pressure or flow transmitters, complementing the discrete status provided by the DI810.

CI854 / CI855: Communication Interface modules. These are the “gateways” that plug into the S800 baseplate, connecting the rack of I/O modules (including the DI810) to a fieldbus network like Profibus DP or to an ABB controller.

SD821 / SD822: System Power Supply units. They provide clean, redundant 24V DC power to the S800 station’s backplane, which powers the DI810 and other modules.

TA510 / TA520: Terminal blocks and field wiring accessories designed for easy and organized connection of field cables to the DI810 module’s front connector.

S800 I/O Baseplate: The physical rack that houses and provides the electrical bus connection for the DI810 and other modules.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB DI810 is straightforward. The terminal block is wired first, then clipped onto the module, which is then snapped onto the DIN rail in the S800 station. It is crucial to use the correct wire gauge and adhere to torque specifications for the terminals. The connected field devices (e.g., sensors) must be powered by a 24V DC supply, which can be separate from or shared with the system logic power, depending on the design.

Maintenance is exceptionally simple. The primary task is monitoring the status LEDs. The hot-swappable design allows for the safe replacement of a module in a live system (if the station configuration supports it). A spare DI810 can be inserted, and it will automatically be recognized and configured by the master controller. We provide comprehensive lifecycle support, from initial system design consultation to supplying guaranteed authentic, factory-fresh or certified refurbished DI810 modules. Our technical team can assist with configuration details and best practices for grounding and wiring to ensure optimal, long-term performance.

Build a reliable foundation for your digital control with robust I/O. Contact us for the genuine ABB DI810 and complete S800 I/O solutions.

-1.jpg)

Reviews

There are no reviews yet.