Application Scenarios:

In a large water treatment facility, a critical raw water intake pump powered by a 2.500 kW high-voltage motor suddenly seizes due to a bearing failure. Without immediate isolation, the stalled motor would overheat within minutes, causing catastrophic insulation failure and a repair costing hundreds of thousands of dollars. The ABB SAFT183VMC protection relay is the dedicated guardian for this motor. It continuously monitors current, voltage, and, through a thermal model, the motor’s temperature. When the bearing fails and the rotor locks, the current skyrockets. The SAFT183VMC instantly detects this locked rotor condition based on the excessive current draw. Concurrently, its internal thermal algorithm calculates the rapid temperature increase. Within milliseconds, and well before thermal damage occurs, it sends a definitive trip signal to the circuit breaker, isolating the motor. It then provides a precise alarm: “Locked Rotor Trip – Thermal Alarm,” enabling maintenance crews to quickly identify the root cause—the failed bearing—and execute a targeted repair. This prevents a simple mechanical failure from escalating into a total electrical burnout, saving weeks of downtime and significant capital expense.

Technical Principles and Innovative Values:

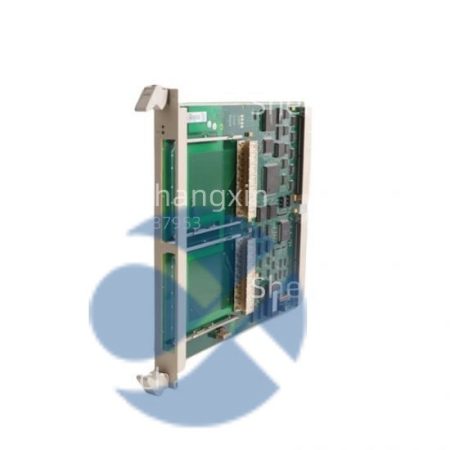

The ABB SAFT183VMC is engineered on the principle of predictive and adaptive protection, moving beyond simple fixed thresholds to model the real-time condition of the equipment it guards.

Innovation Point 1: Dynamic Thermal Model with Cooling Consideration. Unlike conventional overload relays with a fixed time-current curve, the SAFT183VMC employs a sophisticated, configurable thermal model of the motor. It calculates the heating effect of the present current, accounts for heat stored from previous running cycles (thermal memory), and accurately models cooling times during stops. This provides optimal protection by preventing unnecessary trips during legitimate high-load periods while ensuring the motor never exceeds its safe temperature limits, directly extending insulation and overall motor life.

Innovation Point 2: Integrated Sequence of Events (SoE) Recording with High Resolution. The relay acts as a black box for electrical events. It continuously logs time-stamped sequences—trips, alarms, status changes of digital inputs—with millisecond precision. When a fault occurs, the SAFT183VMC doesn’t just say “Overload Trip”; it provides a detailed log showing the current values, preceding alarms, and the exact trigger. This forensic data is invaluable for root cause analysis, drastically reducing troubleshooting time from hours to minutes and preventing recurrent faults.

Innovation Point 3: Comprehensive Asymmetry and Fault Detection. The device goes beyond standard overload protection. It continuously monitors for phase unbalance (a major cause of motor heating), loss of a phase, and negative sequence currents (indicative of internal faults). By detecting these asymmetrical conditions early, the SAFT183VMC can provide an alarm or pre-emptive trip, preventing damage that standard overcurrent protection might miss until it’s too late, thereby protecting both the motor and the driven equipment.

Application Cases and Industry Value:

Case Study: Protecting Critical Conveyor Drives in a Mining Operation

A mining company experienced repeated, unexplained failures of the 1.800 kW drive motors on its main overland conveyor, which transported ore from the pit to the processing plant. Each failure resulted in a 72-hour production stoppage and costly motor rewinds. The existing electro-mechanical relays offered no diagnostic data, making the root cause a mystery.

The solution was to retrofit each motor starter cubicle with an ABB SAFT183VMC protection relay. The relays were programmed with the motor’s exact nameplate and thermal data. Within weeks of operation, a motor tripped. The SAFT183VMC’s event log showed a clear sequence: “Start Command” -> “Current 600% FLC” (Normal start) -> “Current sustained at 250% FLC” -> “Thermal Capacity 100%” -> “Locked Rotor Trip.” The data indicated the motor was starting but not accelerating to full speed, suggesting a mechanical jam. Inspection revealed a seized roller bearing on the conveyor, causing excessive load.

Result: The SAFT183VMC provided the diagnostic clarity needed to shift from electrical to mechanical troubleshooting. The mine implemented a policy where sustained high current alarms from the relay would trigger a conveyor inspection. This proactive approach, enabled by the relay’s intelligence, reduced motor failures on that line to zero for over two years and cut related maintenance costs by an estimated 40%, paying for the retrofit in a few months.

Related Product Combination Solutions:

The ABB SAFT183VMC is the core protection unit within a broader motor management and control scheme. Complementary products include:

ABB Current Transformers (CTs): Such as the ABBH 1A or 5A ring CTs, which provide the scaled current measurement signals to the SAFT183VMC.

ABB Contactor or Circuit Breaker: The switching device (e.g., an A-line contactor or Emax air circuit breaker) that the SAFT183VMC’s trip relay commands to open the motor circuit.

ABB Communication Gateway (e.g., ETH-2): A device that can connect the relay’s serial communication (like Modbus RTU) to an Ethernet network, allowing integration of the SAFT183VMC data into a plant-wide SCADA or asset management system.

ABB CM-PPS Power Supply Module: Provides a stable, filtered 24V DC supply for the relay and other control components, ensuring reliable operation.

ABB PST Softstarter or ACS Variable Speed Drive: For motor control, with the SAFT183VMC providing the ultimate backup protection, communicating fault information to the drive for coordinated shutdown.

ABB CP-S Circuit Breaker Protection Relays: For protecting the feeder circuit breaker upstream of the motor, providing coordinated protection with the SAFT183VMC.

Relay Test Set: Equipment like an OMICRON CMC 356 for commissioning and periodic testing of all the protection functions of the SAFT183VMC.

Installation, Maintenance, and Full-Cycle Support:

Installation of the ABB SAFT183VMC is streamlined for panel builders. The relay is typically DIN-rail mounted. Wiring involves connecting the current transformer secondary circuits, supply voltage, binary inputs (e.g., for remote reset), and output relay contacts to the trip coil of the circuit breaker. Configuration is performed via the front interface or, more efficiently, using ABB’s dedicated configuration software (like PCM600 or a specific tool for the relay), allowing for precise setting of all motor parameters and protection functions.

Routine maintenance is minimal and data-driven. The relay performs continuous self-diagnostics. Engineers should periodically view the event log and thermal capacity readings via the front display or SCADA. The most critical maintenance activity is verifying the protection settings remain correct and performing a primary injection test during scheduled outages to ensure the CT circuits and relay are functioning accurately. We provide comprehensive support for the ABB SAFT183VMC, from the initial selection process—ensuring correct CT ratios and coordinating protection curves—to supplying the unit and configuration software. Our technical team can assist with setting up the thermal model, integrating communications, and interpreting event logs, ensuring you gain the full diagnostic and protective value from your investment.

Looking to prevent catastrophic motor failure and gain deep operational insight? Contact us today for expert advice and reliable supply of the ABB SAFT183VMC motor and generator protection relay for your critical assets.

Reviews

There are no reviews yet.