Application Scenarios

At a nuclear auxiliary cooling water plant in Sweden, pump status feedback was critical for reactor safety. A single-point failure in a legacy I/O card once caused a spurious trip during routine maintenance. To eliminate this risk, engineers upgraded to ABB AC 800M with redundant S800 I/O, using TB850 baseplates (1KGT011900R0001) paired with dual DI651 modules. During a subsequent grid disturbance, one DI651 experienced a transient fault—but the system seamlessly switched to the standby unit within milliseconds. Operators weren’t even alerted until the next shift log review. The 1KGT011900R0001 didn’t just support redundancy—it made resilience invisible.

Technical Principles and Innovative Values

Innovation Point 1: True Hardware Redundancy Without External Logic

The TB850 enables automatic failover at the hardware level—the AC 800M CPU detects module health and switches data paths transparently, eliminating software-based switchover delays.

Innovation Point 2: Unified Field Wiring for Both Modules

Both primary and standby I/O modules connect to the same terminal unit, meaning only one set of field wires is needed—reducing installation cost and wiring errors.

Innovation Point 3: Seamless Integration with Control Builder M

Redundant pairs are configured as a single logical tag in ABB’s engineering tool, simplifying programming and HMI integration.

Innovation Point 4: Diagnostic Coverage for Functional Safety

Continuous monitoring of module sync status, backplane communication, and power integrity supports compliance with IEC 61508 SIL 2 requirements.

Application Cases and Industry Value

A LNG liquefaction train in Qatar implemented ABB 800xA with redundant S800 I/O using 1KGT011900R0001 (TB850) baseplates for all compressor anti-surge control valves. Over three years, the system endured multiple sandstorms and voltage sags. On two occasions, an I/O module failed due to moisture ingress—but redundancy prevented any process upset. The plant achieved 99.98% operational availability, exceeding contractual uptime guarantees. The modest incremental cost of the TB850 baseplate delivered millions in avoided downtime—proving that infrastructure components like the 1KGT011900R0001 are silent guardians of production continuity.

Related Product Combination Solutions

I/O Modules:

DI651 (Digital Input)

DO651 (Digital Output)

AI651 / AO651 (Analog I/O)

Terminal Units:

TU830 (screw-type, IP20)

TU831 (spring-cage, vibration-resistant)

Controllers:

AC 800M PM864 / PM865 (redundant CPU pair)

Communication:

CI854A (Profibus/Modbus gateway)

TB840 (non-redundant baseplate alternative)

Engineering Tools:

Control Builder M (configuration & diagnostics)

System 800xA Asset Optimization

Power:

TK811K / TK812K (redundant I/O power supplies)

Installation, Maintenance, and Full-Cycle Support

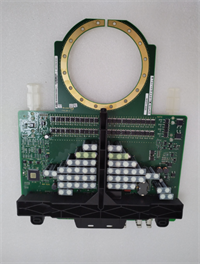

The 1KGT011900R0001 (TB850) mounts directly onto a standard 35 mm DIN rail. It connects to the S800 redundant backplane via two ribbon cables (primary and secondary). A compatible terminal unit (e.g., TU830) snaps onto the front, and two identical I/O modules slide into the top slots until they click.

Key maintenance features:

LED indicators for module presence and communication status

Hot-swap support—failed modules replaced without powering down the rack

Automatic synchronization between primary and standby modules

We perform 100% functional verification on every 1KGT011900R0001. including:

Backplane communication on both redundant channels

Mechanical integrity of module latching

Compatibility with TU830/TU831 terminal units

Firmware handshake with AC 800M (via test rig)

All units include traceable test reports and are verified against ABB’s original specifications.

Contact us for expert support—whether you need a single 1KGT011900R0001 replacement, a full redundant I/O upgrade, or lifecycle extension services for legacy ABB S800 systems. Our team provides compatibility checks, wiring diagrams, and commissioning assistance worldwide.

Reviews

There are no reviews yet.