Application Scenarios

In a large chemical plant, the reliability of the internal 6.6kV distribution network is critical. A fault on a feeder supplying a key production process could lead to an unplanned shutdown, causing significant financial loss and safety risks. The plant engineers upgraded the protection system for their main feeders by installing ALSTOM AL132 relays. One relay was installed on a feeder powering a series of large compressor motors. The relay was configured with directional overcurrent, earth fault, and thermal overload protection. When a downstream cable fault occurred, the AL132’s advanced directional element correctly identified the fault as being on the protected line, not upstream. It initiated a precise, high-speed trip command, isolating the fault in 35 milliseconds. This selective operation prevented the fault from cascading and taking out the entire substation, allowing the rest of the plant to continue running. The integrated event recorder provided a detailed sequence-of-events log, enabling engineers to quickly locate and repair the fault, minimizing downtime.

Technical Principles and Innovative Values

Innovation Point 1: Advanced Protection Algorithms and Flexibility. The ALSTOM AL132 employs sophisticated digital signal processing (DSP) algorithms to analyze current and voltage waveforms with high precision. Beyond standard time-overcurrent curves (IDMT, DT), it offers specialized protection curves for motors, generators, and cables. Its logic and flexibility are enhanced through a configurable scheme logic functionality, allowing users to create custom logic equations using the relay’s inputs, outputs, and internal signals. This enables the implementation of complex interlocking, auto-reclosing sequences, and load shedding schemes without the need for external hardware, simplifying system design and reducing panel space.

Innovation Point 2: Comprehensive Metering, Monitoring, and Diagnostics. The relay acts as a multi-function measurement device, providing highly accurate readings of all key electrical parameters (currents, voltages, power, energy, harmonics). This eliminates the need for separate meters. Integrated disturbance recording (oscillography) and sequence-of-events (SOE) logging with high-resolution time-stamping (often to 1ms) are invaluable for post-fault analysis, allowing engineers to understand the exact sequence of events leading to a trip. Comprehensive self-diagnostics continuously monitor the relay’s hardware and software health, providing early warnings of potential issues.

Innovation Point 3: Modern Communication and Remote Engineering. The AL132 is designed for modern, connected substations. It supports industry-standard communication protocols (Modbus, DNP3. IEC 60870-5-103) via serial and optional Ethernet ports. This allows seamless integration into SCADA (Supervisory Control and Data Acquisition) systems for remote monitoring, control, and data acquisition. Engineers can remotely access the relay’s settings, real-time measurements, and fault records using dedicated configuration software (like MiCOM S1 Studio), enabling efficient management and maintenance of geographically dispersed assets without the need for on-site visits.

Application Cases and Industry Value

Case Study: Enhancing Protection and Automation in a Cement Plant Ring Main Unit.

A cement plant with a 33/6.6kV primary substation and multiple 6.6kV feeders faced challenges with its aging electromechanical protection relays. The system lacked selectivity, leading to unnecessary widespread outages, and provided no remote visibility or fault data, making troubleshooting slow and costly.

Solution: The plant upgraded its key feeder and transformer circuits with ALSTOM AL132 relays. The relays were installed in the switchgear panels, replacing the old units. They were configured with phase and earth fault protection, thermal overload for motors, and voltage protection. All relays were connected via an RS485 multidrop network to a central SCADA system using the Modbus RTU protocol.

Outcome and Value: The new system’s selectivity improved dramatically. A fault on a single conveyor motor feeder was isolated by its specific AL132 relay without affecting other plant sections. The SCADA system now provided real-time power consumption data per feeder, enabling energy management. When a rare voltage dip occurred, the SOE log from the AL132s pinpointed the exact sequence and timing, identifying the cause as a fault on the utility grid. This data reduced fault analysis time from hours to minutes. The plant manager estimated a 30% reduction in unplanned downtime and significantly lower maintenance costs due to predictive insights from the relay’s data.

Related Product Combination Solutions

ALSTOM (GE) MiCOM Px40 Series Relays (e.g., P141. P145): More advanced or specialized relays in the same family, used for busbar protection, transformer differential protection, etc., forming a complete coordinated protection scheme with the AL132.

MiCOM S1 Studio Software: The unified configuration, setting, and monitoring software for the AL132 and other MiCOM relays. Essential for commissioning, managing settings, and retrieving fault records.

Communication Converters/Gateways (e.g., for Profibus, Ethernet/IP): Devices that can be used to integrate the AL132’s serial communication (Modbus) into other industrial networks or protocols used by the main plant PLC/DCS.

Test Equipment (e.g., Omicron CMC Test Set): Advanced secondary injection test sets used to comprehensively test and verify all protection functions, logic, and communication of the AL132 relay during commissioning and periodic maintenance.

Current Transformers (CTs) and Voltage Transformers (VTs): The primary sensors that provide scaled-down, isolated current and voltage signals to the relay’s analog inputs. Their accuracy class directly impacts the relay’s performance.

Circuit Breaker/Fault Making Switch: The primary switching device that the AL132 controls via its trip and close outputs to isolate faults or connect/disconnect the circuit.

Installation, Maintenance, and Full-Cycle Support

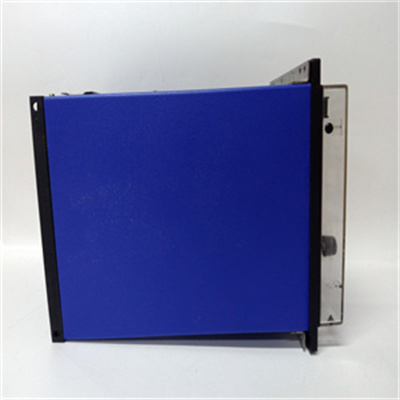

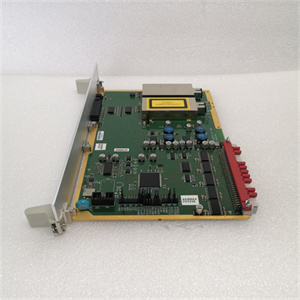

Installation involves panel mounting the ALSTOM AL132 relay, connecting the DC auxiliary supply, wiring the current transformer (CT) and voltage transformer (VT) secondary circuits with proper shorting facilities, and connecting the binary inputs (e.g., circuit breaker status, external alarms) and binary outputs (trip, close, alarm). Communication cabling (shielded, twisted pair for RS485) must be correctly terminated. Initial configuration is performed using MiCOM S1 Studio software via a PC connection to set all protection parameters, logic schemes, and communication addresses.

Routine maintenance includes verifying the health indicators on the relay’s display, checking the integrity of the DC supply, and performing periodic functional tests. The most critical maintenance activity is the periodic secondary injection test using a relay test set to verify the accuracy and timing of all protection functions, ensuring the relay will operate as intended during a real fault. The relay’s non-volatile memory stores all settings and records, preventing loss during power cycles.

We provide comprehensive full-cycle support for the ALSTOM AL132. This includes supplying genuine, factory-sourced or certified refurbished units. Our technical support can assist with:

Design & Specification: Helping select the correct relay model and define the protection scheme.

Configuration & Setting: Guidance on developing appropriate protection settings (coordination studies) and configuring the relay logic.

Testing & Commissioning: Support for on-site commissioning and acceptance testing.

Training: Offering training on the operation, configuration, and maintenance of the AL132 relay.

Repair & Calibration: Providing expert repair, recalibration, and firmware update services to extend the product’s lifecycle.

Migration Services: Assisting in upgrading from older protection relays to the AL132 platform.

Contact us for expert support on protection and control solutions, including the ALSTOM AL132 relay, from system design to long-term maintenance.

Reviews

There are no reviews yet.