Description

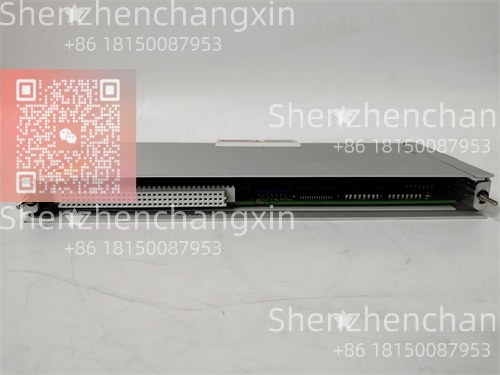

The BENTLY NEVADA 125720-01 is an Enhanced Keyphasor® Module designed for the industry-standard 3500 Machinery Protection System. As a critical component in rotor dynamic monitoring, it provides two independent, high-fidelity Keyphasor input channels that deliver precise once-per-revolution timing signals—enabling accurate speed measurement, phase reference for vibration analysis, and time-synchronized diagnostics such as orbit plots, Bode plots, and polar maps.

Engineered for reliability in harsh industrial environments, the 125720-01 features advanced signal conditioning, automatic threshold adjustment, and comprehensive self-diagnostics, making it indispensable for protecting turbines, compressors, pumps, and generators against catastrophic failure.

Application Scenarios

At a combined-cycle power plant in the Middle East, operators struggled with inconsistent speed readings during gas turbine startups, leading to unreliable vibration trend data and delayed commissioning. The root cause was traced to an aging single-channel Keyphasor module unable to handle signal noise from nearby high-voltage cabling. After installing the BENTLY NEVADA 125720-01. the system delivered clean, stable once-per-turn pulses—even at cranking speeds below 50 RPM. During the next hot startup, the 125720-01 enabled real-time orbit plot generation that revealed a developing rub in the #3 bearing, allowing engineers to adjust clearances before full load. Over the following year, the module’s dual-channel redundancy ensured zero missed trips during transient events, and its diagnostic LEDs instantly flagged a failing magnetic pickup during routine rounds—preventing a potential overspeed incident. The 125720-01 didn’t just measure rotation—it became the heartbeat of the plant’s machinery health strategy.

Parameter

表格

Note: Requires 3500/25 interface modules (e.g., 125840-01) and proper backplane configuration.

Technical Principles and Innovative Values

Innovation Point 1: Adaptive Signal Thresholding – The 125720-01 automatically adjusts trigger levels based on real-time signal amplitude, ensuring reliable pulse detection across wide speed ranges—from turning gear to full load—without manual recalibration.

Innovation Point 2: Dual Independent Channels with Isolation – Each channel operates autonomously with galvanic isolation, allowing simultaneous connection to different sensor types (e.g., proximity probe on one, magnetic pickup on the other) for cross-verification or backup.

Innovation Point 3: Foundation for Advanced Diagnostics – By providing a precise phase reference, the 125720-01 enables time-synchronous averaging, shaft centerline plots, and startup/shutdown trend analysis—critical for identifying imbalance, misalignment, looseness, and resonance.

Innovation Point 4: Seamless Integration with 3500 Ecosystem – Speed and phase data from the 125720-01 are shared across all 3500 monitor modules (e.g., 3500/42M, /44. /62) via the backplane, eliminating external wiring and ensuring synchronized machine protection logic.

Application Cases and Industry Value

During a turnaround at a U.S. Gulf Coast ethylene cracker, a cracked compressor rotor was discovered only after a near-catastrophic failure. Post-incident analysis showed that early-stage crack signatures were present in vibration data—but without a reliable Keyphasor reference, phase trends went unnoticed. The site upgraded all critical trains with redundant BENTLY NEVADA 125720-01 modules. Six months later, during a planned ramp test, the 125720-01-enabled Bode plot revealed a 12° phase shift at critical speed—indicative of a developing crack. The compressor was safely removed before failure, avoiding an estimated $ 15M in collateral damage and 45 days of downtime. Maintenance teams now use 125720-01 data for monthly rotor health reviews, reducing unscheduled outages by 65%. The module proved that in rotating machinery, knowing when a vibration occurs is as vital as knowing how much.

Related Product Combination Solutions

3500/25 Chassis: Main rack housing for 125720-01 and other 3500 I/O modules.

125840-01: 3500/25 Interface Module—required for communication between 125720-01 and system controller.

3500/42M: 4-Channel Vibration Monitor—uses 125720-01 phase data for orbit and spectrum analysis.

3500/62: Process Variable Monitor—can correlate speed (from 125720-01) with pressure/flow for surge detection.

System 1 Software: Bently’s asset management platform for viewing 125720-01-enabled diagnostics.

3300 XL Proximity Probes: High-performance sensors optimized for use with 125720-01.

3500/50: Overspeed Protection Module—uses 125720-01 speed signals in 2oo3 voting for trip logic.

146039-01: Keyphasor Extension Cable—ensures signal integrity over long runs.

Installation, Maintenance, and Full-Cycle Support

Installing the BENTLY NEVADA 125720-01 requires mounting it in a 3500/25 chassis alongside required interface modules. Field wiring connects via terminal blocks to proximity probes or magnetic pickups, using shielded twisted-pair cable with single-point grounding to minimize noise. Configuration is performed in Rack Configuration Software (RCS), where users define sensor type, enable diagnostics, and assign channels to protection functions.

Routine maintenance involves visual inspection of front-panel LEDs and periodic verification using System 1 software. The module continuously monitors for open circuits, short circuits, and signal dropout—logging faults for predictive intervention. If replacement is needed, the 125720-01 can be swapped in minutes with no calibration required, thanks to its plug-and-play design. Every unit we supply undergoes full functional testing, including low-speed pulse validation and noise immunity checks. Backed by a 12-month warranty and access to Bently-certified application engineers, we ensure your Keyphasor reference remains the most trusted signal in your machinery protection system.

Contact us for a customized solution—whether you need a single 125720-01 for emergency repair or a complete rotor monitoring strategy for your next critical machine upgrade.

Reviews

There are no reviews yet.