Application Scenarios

At a North Sea offshore platform, a main refrigeration compressor suffered repeated bearing failures due to subsynchronous oil whirl—a phenomenon invisible to standard 10 kHz monitoring systems. After installing the BENTLY NEVADA 125388-01H on all four bearing positions, engineers captured high-frequency resonance signatures at 18 kHz during startup transients. Using System 1’s orbit and cascade plots, they identified a rotor instability mode and adjusted lube oil pressure setpoints. Over the next 24 months, unplanned shutdowns dropped by 90%, saving an estimated $ 4.2M in avoided downtime and repair costs. This case demonstrates how the 125388-01H transforms raw vibration into actionable mechanical intelligence.

Technical Principles and Innovative Values

Innovation Point 1: True Simultaneous Sampling Across All Channels

Unlike sequential-scan modules, the 125388-01H captures all four channels at the exact same instant—preserving phase relationships essential for accurate orbit, shaft centerline, and modal analysis.

Innovation Point 2: 100 kHz Bandwidth for Emerging Failure Modes

Enables detection of high-frequency phenomena like blade pass, cavitation, gear mesh, and electrical discharge machining (EDM) currents in VFD-driven motors—often missed by legacy 10 kHz systems.

Innovation Point 3: Seamless API 670 Compliance with Flexible Alarming

While primarily a data acquisition module, it feeds real-time waveforms to the 3500/42M or 3500/45 monitor modules for trip logic, satisfying API 670 requirements for both protection and diagnostics.

Innovation Point 4: Cyber-Secure Data Path

When used with System 1 v22+, data is encrypted in transit and access-controlled via role-based authentication—meeting IEC 62443 cybersecurity standards for OT environments.

Application Cases and Industry Value

Refinery Hydrocracker Recycle Gas Compressor:

Installed 125388-01H modules detected early-stage cracked impeller blades via sideband modulation at 42 kHz. Early intervention avoided a catastrophic rupture—preventing a potential $ 20M incident.

Nuclear Power Plant Main Feedwater Pumps:

Used for baseline testing during commissioning; the high-fidelity data became the reference for all future performance audits, supporting regulatory compliance (10 CFR 50 Appendix B).

LNG Train Centrifugal Compressors:

Integrated with digital twin models; real-time dynamic data from 125388-01H validates simulation assumptions during turndown operations.

Related Product Combination Solutions

3300 XL 8 mm Proximity Probe: Standard sensor paired with 125388-01H for shaft vibration.

3500/42M Monitor: Processes 125388-01H data for alarm/trip logic with enhanced diagnostics.

3500/33 Relay Module: Provides fail-safe relay outputs based on vibration thresholds.

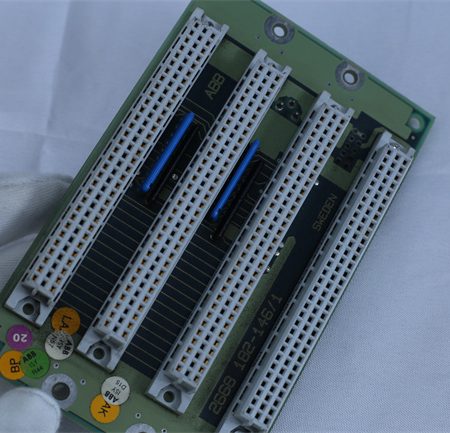

3500/50 Chassis: Required backbone for high-speed dynamic modules.

GE Mark VIe: In combined-cycle plants, vibration data from 125388-01H is often correlated with turbine control events via OPC.

System 1 Software: Essential for visualization, trending, and automated diagnostics.

Bently Nevada 146039-01: Extension cable for probe-to-module connection.

Rockwell 1756-L83E: PLC that ingests 125388-01H health data via Modbus TCP for asset management.

Installation, Maintenance, and Full-Cycle Support

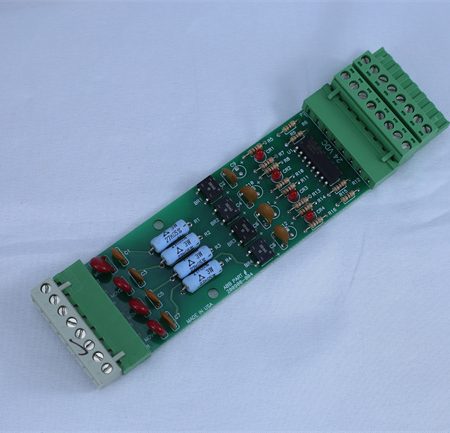

Installation requires mounting in a 3500/50 or compatible chassis with proper grounding and shielded BNC or LEMO cabling from sensors. Each channel must be configured in Rack Configuration Software(RCS) for sensor type, range, and engineering units.

Maintenance involves periodic verification using the 3500/50’s built-in test features and cross-checking with portable analyzers. The module performs continuous self-diagnostics—reporting faults like open circuits or excessive noise directly to System 1.

We supply only genuine BENTLY NEVADA 125388-01H modules—new surplus or factory-refurbished—with full functional validation including:

100 kHz sine wave response test

Cross-channel phase accuracy (<1° error)

Anti-alias filter roll-off verification

Thermal soak testing (–30°C to +70°C)

Each unit includes original firmware, calibration certificate, and 12-month warranty. Our team includes ex-Bently field application engineers who provide free startup support and spectral interpretation guidance.

Contact us for a customized solution—whether you’re protecting a single critical pump or deploying a fleet-wide condition monitoring strategy, the BENTLY NEVADA 125388-01H delivers unmatched fidelity, reliability, and insight where machine integrity matters most.

Reviews

There are no reviews yet.