Application Scenarios

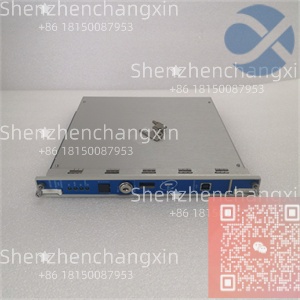

In a large natural gas compression station, multiple high-speed centrifugal compressors are protected by a Bently Nevada 3500 system. This system continuously monitors vibration, speed, and temperature to prevent catastrophic failures. The reliability of every single monitoring module depends on a clean, stable power source. The Bently Nevada 3500/65 172103-01 module is installed in the power supply slot of the 3500 rack. In a typical configuration, two of these modules are installed in a redundant setup. They share the load and, if the primary module fails, the secondary seamlessly takes over 100% of the load without any interruption to the monitoring and protection functions. This redundancy, enabled by the 3500/65. ensures that a power supply failure does not blind the protection system, allowing it to continue safeguarding millions of dollars worth of critical rotating equipment 24/7. even during a component fault.

Parameter

Annotation: The part number 172103-01 is the specific item code. The 3500/65 is the generic model designation for the power supply module family. Its most critical feature is N+1 redundancy capability, which is a fundamental requirement for high-availability safety and protection systems.

Technical Principles and Innovative Values

The Bently Nevada 3500/65 172103-01 is engineered not just as a simple converter, but as a highly reliable, fault-tolerant power source for mission-critical monitoring systems.

Innovation Point 1: True N+1 Redundancy with Load Sharing and Hot Swap. The module is designed from the ground up for parallel, redundant operation. Two modules actively share the rack’s total power load. This load sharing reduces thermal stress on each unit, extending their operational life. If one module fails, the other instantly and transparently assumes the full load. Crucially, the faulty module can be safely extracted and a new one inserted while the system remains online, ensuring zero downtime for the protection system—a vital feature for continuously operating processes.

Innovation Point 2: Intelligent Diagnostics and Communication. Unlike a basic power supply, the 3500/65 is an intelligent part of the 3500 system. It communicates its status (output voltage, temperature, load) and any internal faults (overload, over-temperature, input failure) to the rack’s monitoring modules (like the 3500/15 or 3500/22). This allows predictive maintenance; personnel can be alerted to a degrading power supply beforeit fails, and schedule its replacement during a planned maintenance window, moving from reactive to proactive upkeep.

Innovation Point 3: Wide-Range Input and High Noise Immunity. The module accepts a very wide range of input voltages (both AC and DC), making it adaptable to various plant power conditions around the world without needing a separate transformer. Furthermore, it includes extensive filtering and protection circuits to suppress electrical noise, spikes, and transients commonly found in industrial environments. This ensures clean, stable power is delivered to the sensitive monitoring electronics, guaranteeing measurement accuracy and system stability.

Application Cases and Industry Value

Case Study: Ensuring Uninterrupted Protection in a Combined-Cycle Power Plant

A combined-cycle power plant’s gas turbine supervisory system relied on a Bently Nevada 3500 rack for vibration protection. During a severe summer storm, a voltage sag and surge affected the plant’s electrical system. The Bently Nevada 3500/65 172103-01 power supply in slot 1 experienced an internal fault due to the surge. Instantly, the redundant 3500/65 module in slot 2 took over the entire load without a single blip in the monitoring system. The 3500 software immediately generated an alarm indicating “Power Supply A Failure,” guiding maintenance to the exact issue. Technicians replaced the faulty module the next day during normal operations. The turbine protection never faltered, allowing the plant to continue running at full capacity during peak demand, avoiding an estimated $250.000 in lost revenue that would have resulted from a forced shutdown for repairs.

Case Study: Preventing False Trips in a Offshore Oil Platform’s Critical Pump

On an offshore platform, a seawater injection pump’s 3500 monitoring system experienced intermittent, unexplained vibration alarms. Investigation ruled out mechanical issues. Closer inspection of the system diagnostics revealed occasional, minor fluctuations in the +15V supply rail from the primary 3500/65 module, correlated with the starts of other large motors on the same electrical bus. The degraded filtering in the aging power supply was allowing noise to affect the sensitive analog vibration channels. Replacing both 3500/65 172103-01 modules as a preventive pair eliminated the noise and the false alarms. This prevented a potential costly and unnecessary shutdown of a critical pump based on a faulty signal, showcasing how a reliable power supply is foundational to signal integrity and overall system trustworthiness.

Related Product Combination Solutions

Bently Nevada 3500/15 or 3500/22: These are Transient Data Interface or Monitoring modules. They are the “brains” of the rack that receive power from the 3500/65 and in turn collect data from all other modules, providing the main system interface.

Bently Nevada 3500/25 or 3500/32: Vibration monitoring modules. These critical input modules rely on the clean, stable power from the 3500/65 to accurately process microvolt-level signals from proximity probes.

Bently Nevada 3500/42M Proximitor Power Supply: This module provides the excitation voltage to the vibration probes themselves. It is also powered by the 3500/65. creating a clean power chain from the rack all the way to the sensor.

Bently Nevada 3500/33 Relay Module: A critical output module that sends trip signals. Its reliable operation is completely dependent on the uninterrupted power from the 3500/65.

Bently Nevada 3500 Rack Frame (e.g., 4-slot, 8-slot, 12-slot): The physical chassis that houses the 3500/65 power supplies and all other monitoring modules, providing the backplane for power distribution and communication.

Bently Nevada 3300 XL Proximitor Probes: The actual sensors mounted on the machinery. While not directly powered by the 3500/65. they are part of the ecosystem whose integrity starts with the rack’s power supply.

System 1 Evolution Software: The plant-wide monitoring software that receives data from the 3500 rack. A failure of the 3500/65 would cause loss of data to this system, highlighting the PSU’s role in the entire data chain.

Installation, Maintenance, and Full-Cycle Support

Installation of the Bently Nevada 3500/65 172103-01 involves inserting it firmly into one of the dedicated power supply slots (typically slots 1 and/or 2) in the 3500 rack frame. The input power wiring (AC or DC) must be connected to its terminal block following local electrical codes and the manual’s specifications, paying close attention to proper grounding. For redundant operation, a second module is installed and connected to a separate, independent power sourcewhere possible, to protect against a single source failure. Configuration is minimal, as the module is self-identifying to the rack.

Maintenance is centered on predictive diagnostics and proactive replacement. The module’s health should be monitored via the 3500 system’s software, watching for any alerts related to power supply status, load share imbalance, or temperature. Many facilities adopt a preventative maintenance strategy of replacing power supply modules after a certain number of years in service, given their critical role. Replacement is straightforward due to hot-swap capability: with a redundant partner online, the module to be replaced can be unlocked and pulled straight out, and the new module inserted. The rack will automatically recognize it and integrate it into the redundant pair. Our full-cycle support for the 3500/65 includes providing detailed wiring diagrams, assisting with system health checks, and supplying genuine, factory-tested replacement modules. We can also help with compatibility verification for system expansions or upgrades, ensuring your machinery protection system’s most fundamental component—its power—remains utterly reliable.

The integrity of your machinery protection system starts with clean, reliable power. Ensure your system’s foundation is solid. Contact us for technical support, diagnostics, and sourcing for genuine Bently Nevada 3500/65 172103-01 Power Supply Modules and related components.

-1.jpg)

Reviews

There are no reviews yet.