Product Overview

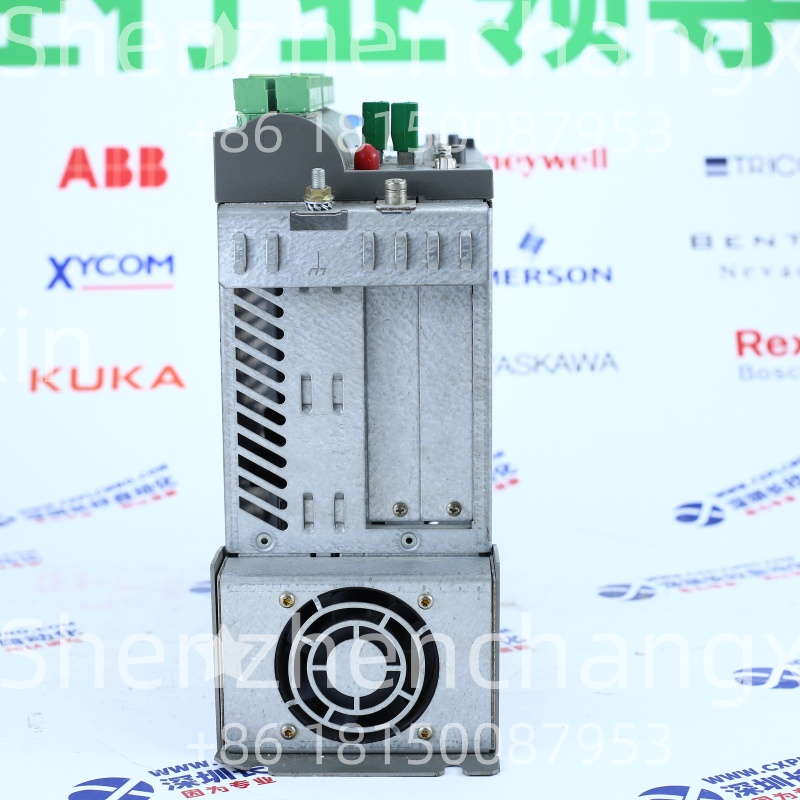

In modern automation equipment that demands high dynamic response and system simplification, the ELAU C200/10/1/1/1/00 represents a “decentralized intelligence” design concept – pushing control logic down to the drive level to achieve “Drive-Based Control”.

🔍 Model Analysis (C200/10/1/1/1/00):

C200: Product series

10: Continuous output current is 10 A (peak current is typically 2–3 times higher)

First 1: Power input is three-phase 200–480 V AC

Second 1: Motor feedback interface is EnDat / Hiperface / Resolver (this model defaults to EnDat 2.2)

Third 1: Communication protocol is CANopen (DS402)

00: Standard function version (no special customization)

This drive features a compact book-style mounting design, allowing for direct installation in the electrical cabinet or near the motor, reducing wiring. Its core advantage lies in “single-drive complete machine control” – for example, in a pillow packaging machine, only one C200 is needed to coordinate multiple servo axes such as the main motor, longitudinal sealing, transverse sealing, and feeding, significantly reducing system complexity and cost.

Technical Specifications

Table

Main Features and Advantages

* Integrated intelligent control: No external PLC is required; a single drive can achieve complete machine logic and multi-axis coordination, shortening development cycles.

* High dynamic performance: Current loop response < 50 µs, position loop bandwidth > 1 kHz, meeting the needs of high-speed and high-precision applications.

* Flexible communication: CANopen interface facilitates connection to HMI, sensors, or other CANopen devices; it can also be connected to EtherNet/IP or PROFINET via a gateway.

* Rich motion library: Built-in dedicated function blocks such as PackML, flying shear, and winding accelerate industry application development.

* Diagnostic and maintenance friendly: Front panel LEDs indicate status, and fault logs and oscilloscope data (Scope function) can be read via USB or CANopen. Typical Application Scenarios

Food Packaging Machinery: Main drive, horizontal sealing, and vertical sealing synchronous control in pillow packaging machines and vertical packaging machines.

Labeling and Printing Equipment: Tension control and registration in intermittent labeling machines and flexographic printing presses.

Material Handling: Delta robots and SCARA robot joint drives.

Wood Processing: Multi-axis coordination in automatic panel saws and edge banding machines.

OEM Equipment Integration: Used as a standardized intelligent drive unit to quickly build modular equipment.

Installation and Configuration Recommendations

Cooling Space: Ensure at least 50 mm of cooling clearance above and below to avoid overheating and derating.

Feedback Cable: Use original or shielded twisted-pair feedback cables, length ≤ 15 meters (EnDat signals are sensitive to interference).

CANopen Termination Resistor: 120 Ω termination resistors must be enabled at both ends of the network (C200 modules usually have built-in DIP switches).

Programming Tools: Use Elau SyPT Pro or Schneider EcoStruxure Machine Expert (formerly PacDrive) for parameter setting and program downloading.

Safety Functions: If STO (Safe Torque Off) is required, confirm that the model includes the safety option (this model C200/10/1/1/1/00 usually does not include STO; the /S version is required).

Lifecycle and Procurement Recommendations

As of 2026, the ELAU C200 series has been gradually integrated into Schneider Electric’s PacDrive 3 ecosystem, but the C200/10/1/1/1/00 is still in a “Limited Availability” status, mainly for existing equipment maintenance.

New Projects: Schneider recommends switching to the PacDrive 3 MDrive series (such as LXM32A), which supports EtherCAT and offers higher power density.

Spare Parts Procurement: For in-service C200 equipment, it is recommended to stock up on key models as soon as possible, as they may be discontinued in the future.

Compatibility Note: Firmware and programming software versions must match; older versions of SyPT may not support newer versions of Windows. Shenzhen Changxin promises that all supplied ELAU C200/10/1/1/1/00 units are brand new or high-quality stock products from Schneider Electric, and come with factory test reports. Each drive undergoes power-on self-test, CANopen communication verification, motor simulated load testing, and parameter initialization. It is backed by a 12-month warranty and SyPT configuration file recovery service, helping you ensure continuous production line operation.

Technical Summary (English):

The ELAU C200/10/1/1/1/00 is an intelligent servo drive from Schneider Electric, integrating motion control, logic control, and power amplification in a single compact unit. With 10 A continuous current, CANopen communication, and built-in IEC 61131-3 PLC functionality, it enables standalone machine control for applications like packaging, printing, and robotics. Featuring high dynamic response, electronic camming, and flying shear capabilities, it reduces system complexity and cost. While newer PacDrive 3 platforms are now preferred for new designs, the C200 remains critical for maintaining existing high-performance machinery.

Reviews

There are no reviews yet.