Application Scenarios

At a European pharmaceutical packaging line, a blister-sealing machine relied on an ELAU MC-41110400 to synchronize film unwinding, tablet indexing, heat sealing, and cutting—all at 400 cycles per minute. The controller’s ability to execute electronic gearing and flying shear profiles via Sercos II ensured micron-level registration accuracy. When the original unit failed after 12 years of continuous operation, production halted at a cost of €80K/hour. A fully tested replacement MC-41110400—with verified Sercos II sync and program integrity—was installed within 8 hours, restoring full throughput without re-engineering.

This case underscores the MC-41110400’s role not just as hardware, but as the irreplaceable timing core of high-precision machinery where migration is prohibitively expensive or technically unfeasible.

Technical Principles and Innovative Values

Innovation Point 1: Tight PLC-Motion Integration

Unlike traditional architectures that separate logic and motion controllers, the MC-41110400 executes both on a single processor with shared memory. This eliminates communication latency between safety interlocks (e.g., emergency stop) and motion responses—critical for high-speed machines where a 10 ms delay could cause jams or damage.

Innovation Point 2: Sercos II Real-Time Performance

Using optical fiber-based Sercos II, the controller achieves deterministic, noise-immune communication with servo drives. All position, velocity, and status data are exchanged in a single cyclic telegram, enabling true multi-axis synchronization for applications like flying cutoff or coordinated robotics.

Innovation Point 3: Advanced Motion Function Blocks

The controller supports pre-certified IEC 61131-3 function blocks for CAM tables, electronic line shafting, flying shear, and contouring. These reduce development time and ensure motion profiles meet mechanical stress limits.

Innovation Point 4: Non-Volatile Program Storage

Programs and motion parameters are stored in onboard flash memory, eliminating battery dependency. This ensures configuration retention during power loss—a key advantage over RAM-based competitors.

Application Cases and Industry Value

Case Study: Flexible Food Packaging Line (Italy)

A snack food producer used the MC-41110400 to control a form-fill-seal machine handling multiple bag formats. The controller switched CAM profiles on-the-fly based on product type, maintaining ±0.2 mm cut accuracy at 120 bags/minute. Over 10 years, zero motion-related downtime was recorded.

Case Study: Labeling Machine Retrofit (USA)

An OEM retrofitted aging DC motor systems with AC servos driven by MC-41110400. The upgrade improved label placement accuracy by 40% and reduced maintenance costs by eliminating tachometers and analog cards.

Related Product Combination Solutions

For complete system deployment or spare support, the MC-41110400 is commonly used with:

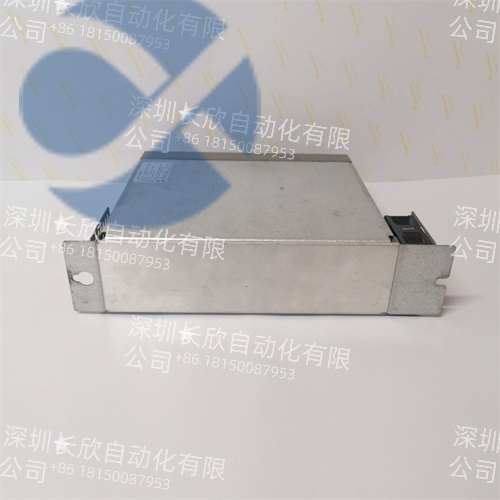

ELAU SmartCrate Base Units (e.g., BC-1000) – Power and backplane

ELAU Servo Drives – e.g., CD-4×00 series (Sercos II compatible)

PAS4000 / PASmotion Software – Official programming and tuning suite

Sercos II Optical Hubs & Cables – For multi-drop drive networks

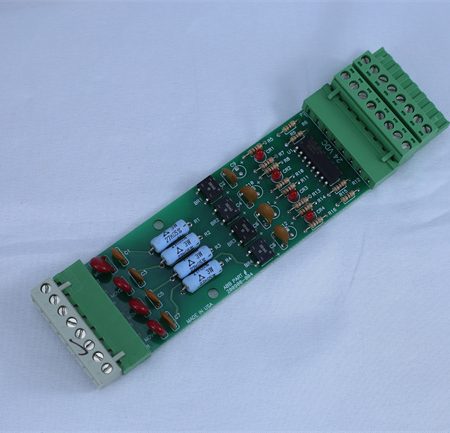

ELAU I/O Modules – e.g., DI/DO modules for machine sensing and actuation

Backup Battery Module (if applicable for older variants)

⚠️ Note: Schneider Electric has discontinued the ELAU SmartCrate line. New units are no longer available; only refurbished or surplus stock exists.

Installation, Maintenance, and Full-Cycle Support

Installation requires:

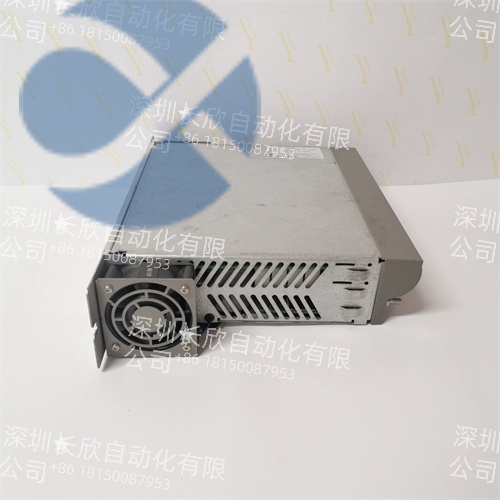

Secure mounting in a SmartCrate-compatible enclosure

Proper termination of Sercos II optical fibers (avoid sharp bends)

Grounding per EMC guidelines to prevent signal jitter

Maintenance best practices:

Keep firmware and project backups archived

Inspect optical connectors for dust/scratches annually

Monitor drive sync errors via diagnostic LEDs

As a specialized provider of legacy automation components, we offer fully tested ELAU MC-41110400 units that undergo:

✅ Power-up self-test verification

✅ Sercos II loopback and sync validation

✅ Memory integrity check

✅ Functional test with simulated motion profile

✅ Cleaned and inspected for capacitor/component aging

Each unit includes a 24-month warranty, firmware version report, and technical support for integration or emergency swap-out.

Reviews

There are no reviews yet.