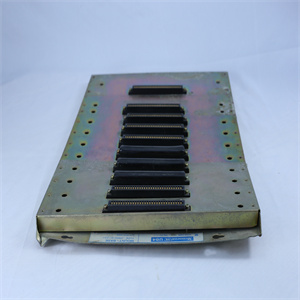

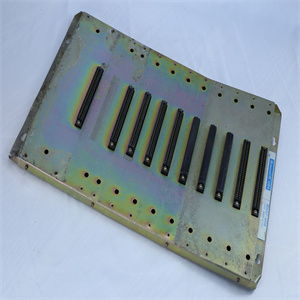

Product Overview

The Yaskawa CACR-HR03BAB11Y40 Servopack is a legacy model within Yaskawa’s robust CACR-HR series of AC servo drives,commonly known as”Servopacks.”This particular unit is a multi-function position controller,designed to precisely manage the motion of AC servomotors in a wide array of industrial automation applications.Although from an older generation compared to Yaskawa’s current Sigma series,the CACR-HR series was a staple for its reliability,high accuracy,and quick response.

The design of the CACR-HR03BAB11Y40 leverages Yaskawa’s extensive expertise in motion control,providing a stable and accurate control operation even under challenging environmental conditions.It is typically rack-mounted,contributing to space conservation in control cabinets.A key strength of the CACR-HR series lies in its comprehensive display functions and protective features,which aid in easy maintenance and ensure reliable operation by safeguarding against various potential issues like overvoltage,overcurrent,and overheating.

This Servopack primarily functions as a position controller,making it suitable for applications requiring precise point-to-point positioning.It operates by receiving commands and sending power to a matched Yaskawa AC servomotor,which includes an encoder for feedback,ensuring closed-loop control and highly accurate motion.Its versatility and robust construction made it a popular choice for integrating into various types of machinery requiring precise and dynamic motion control.

Technical Specifications

While specific detailed technical specifications for the exact Yaskawa CACR-HR03BAB11Y40 are part of detailed product manuals,we can infer general specifications based on the CACR-HR series and common Yaskawa servo drive characteristics of that era.The”03″in the model number typically indicates a 0.3 kW(300W)output capacity.

Parameter Name

Parameter Value(Typical for CACR-HR03B series)

Product Model

CACR-HR03BAB11Y40

Manufacturer

Yaskawa Electric Corporation

Product Type

AC Servopack(Servo Drive/Amplifier)

Series

CACR-HR Series

Control Method

Position Control,Speed Control(General Purpose Multi-function)

Compatible Motor Series

Yaskawa USAMED,USAFED,USAGED,USASEM,USAREM,USAPEM series(e.g.,USAMED-03M)

Output Capacity

0.3 kW(300 W)-Indicated by”03″in model name

Input Voltage

Typically Single-phase 100V AC or 200V AC(varies by specific model)

Input Frequency

50/60 Hz

Feedback System

Compatible with incremental encoders(e.g.,6000 P/rev,5000 P/rev,4000 P/rev)

Control Modes

Position,Speed,Torque

Control Accuracy

High accuracy for speed and position control

Response

Quick response

Cooling Method

Natural air cooling/Forced air cooling(depending on model)

Ambient Temperature

0 to+40°C(32 to 104°F)

Ambient Humidity

20%to 80%RH(non-condensing)

Vibration Resistance

15µm or below

Protection Functions

Overvoltage,Overcurrent,Overheat,Encoder error,Overload,etc.

Mounting Type

Rack-mounted type

Display

Various display functions(e.g.,LED alarm indications)

Wiring

Unshielded or shielded twisted pair for signal/encoder lines(up to 20m for PG feedback)

Place of Origin

Japan

Note on Model Number Breakdown(General Yaskawa CACR-HR convention):

CACR-HR:Series designation.

03:Output capacity(e.g.,0.3 kW).

B:Input voltage(e.g.,200V).

AB:Control method or specific variant.

11:Likely version or minor revision.

Y40:Special specification or customization code.This part often indicates specific modifications,custom software,or specialized I/O.Without specific documentation,its exact meaning can only be inferred as a variant.

Main Features and Advantages

The Yaskawa CACR-HR03BAB11Y40 Servopack offers several key features and advantages that contributed to its widespread use in various industrial automation applications:

1.High Accuracy and Quick Response:

Precision Control:Engineered with Yaskawa’s advanced control algorithms,this Servopack provides high-accuracy positioning and speed control.This is critical for applications demanding tight tolerances and repeatable movements.

Fast Dynamics:It delivers a quick response,meaning it can rapidly react to command changes and load variations,contributing to reduced cycle times and improved productivity in automated processes.

2.Multi-Functionality and Versatile Control Modes:

General Purpose Controller:Designed as a general-purpose,multi-function controller,it can handle various control modes,primarily position and speed control.This versatility allows it to be adapted to a broad range of machine types and motion profiles.

Integrated Positioning Control:It functions as a position controller,simplifying the architecture for point-to-point motion applications by integrating digital positioning capabilities directly into the drive.

3.Robustness and Reliability:

Industrial-Grade Design:Built to withstand typical industrial environments,it features robust protective functions against common electrical and operational issues such as overvoltage,overcurrent,and overheating.This enhances the longevity and reliability of both the Servopack and the connected machinery.

Self-Protective Functions:Various built-in protective circuits and alarm indications help prevent damage to the drive and motor,reducing the risk of unexpected downtime.

4.User-Friendly and Maintainable:

Rack-Mounted Design:Its rack-mounted form factor helps conserve mounting space within control cabinets,contributing to a more compact machine design.

Diagnostic Features:Equipped with various display functions and LED alarm indications,it provides clear diagnostic feedback,simplifying troubleshooting and maintenance procedures for operators and technicians.

Ease of Operation:While requiring proper setup,the design aims for easy and flexible operation through its control interface,supporting efficient machine operation.

5.Compatibility with Yaskawa Servo Motors:

Optimized System Performance:Designed to seamlessly integrate with Yaskawa’s specific AC servomotor series(e.g.,USAMED,USAFED,USAREM),ensuring optimal performance of the complete servo system.This integrated design guarantees that the motor and drive work in harmony for maximum efficiency and precision.

Application Field

The Yaskawa CACR-HR03BAB11Y40 Servopack,as part of the CACR-HR series,was widely applied in various industrial automation sectors due to its capabilities in high-accuracy positioning and speed control.Its design made it particularly suitable for discrete manufacturing and precise motion applications.

Some common application fields include:

Assembly Robots and Manipulators:Provides the necessary precision and dynamic response for robotic arms performing assembly tasks,pick-and-place operations,or material handling.

Chip Mounters(Electronics Manufacturing):Critical for the high-speed and high-accuracy placement of electronic components onto PCBs in surface-mount technology(SMT)lines.

Small-type X-Y Tables:Used in precision positioning systems for inspection,dispensing,cutting,or drilling applications where accurate movement across two axes is required.

Coil Winding Machines:Ensures precise winding of wires for motors,transformers,and other electrical components,controlling the speed and tension of the winding process.

Packaging Machinery:Provides accurate motion control for various functions like precise filling,sealing,cutting,and conveying in packaging lines,optimizing throughput and product quality.

Textile Machinery:Used in applications requiring precise control of fabric movement,needle positioning,or cutting operations.

Printing Machinery:Ensures accurate registration and movement of print heads or paper,contributing to high-quality print output.

Material Handling Systems:Employed in conveyor systems,automated storage and retrieval systems(AS/RS),and other material transfer applications where precise starts,stops,and positioning are needed.

General Industrial Machinery:Found in a broad range of machines requiring repeatable,accurate,and high-speed motion,such as feeders,loaders,and specialized processing equipment.

Due to its”general-purpose multi-function”nature and focus on accurate,quick-response control,the CACR-HR03BAB11Y40 was an ideal choice for machinery where motion precision directly impacts product quality and production efficiency.

Related Products

The Yaskawa CACR-HR03BAB11Y40 Servopack is a component within a broader ecosystem of Yaskawa motion control products.Its functionality is intrinsically linked to the motors it drives and is often part of a larger automation system.

1.Compatible Yaskawa AC Servomotors:

USAMED Series:Medium inertia,high-speed motors.

USAFED Series:Flat-type motors.

USAGED Series:High-inertia motors.

USAREM Series:Medium inertia motors,often paired with the CACR-HR series.

USAPEM Series:High-resolution motors.

(The”03″in CACR-HR03BAB11Y40 typically implies it pairs with a 0.3 kW motor,e.g.,USAMED-03M or similar.)

2.Cables and Connectors:

Power Cables:Connect the Servopack to the main power supply and to the servomotor’s power terminals.

Encoder Feedback Cables(PG Cables):Connect the servomotor’s encoder to the Servopack to provide position and speed feedback.

I/O and Control Signal Cables:Connect the Servopack to the host controller(PLC/motion controller)for command signals(e.g.,pulse train,analog voltage)and status feedback.

3.Host Controllers/Motion Controllers:

PLCs(Programmable Logic Controllers):For executing sequential control logic and sending motion commands to the Servopack.

Dedicated Motion Controllers:Such as Yaskawa’s MP(Machine Controller)series(e.g.,MP2000 series,MP3000 series)or older models,which provide advanced motion programming capabilities.

HMI(Human Machine Interface)Panels:Used for operator interaction,monitoring system status,and adjusting parameters.

4.Power Supply and Braking Resistors:

Regenerative Braking Units/Resistors:For dissipating excess energy generated by the servomotor during deceleration,especially in high-dynamic applications.

Line Filters/Reactors:Used to improve power quality and reduce electrical noise.

5.Software Tools:

Yaskawa Configuration Software:Software used for parameter setting,tuning,diagnostics,and monitoring of the Servopack.(Specific software would depend on the series’generation,often DOS-based or early Windows-based for the CACR series).

6.Newer Yaskawa Servo Drives(Successors/Upgrades):

Sigma Series(e.g.,Sigma-I,Sigma-II,Sigma-V,Sigma-7,Sigma-X):These are the newer generations of Yaskawa Servopacks,offering higher performance,more advanced features,improved communication options(e.g.,MECHATROLINK,EtherCAT),and higher resolution encoders.When the CACR-HR03BAB11Y40 is no longer available or suitable for modern applications,these newer series are the direct upgrade path.

Installation and Maintenance

Pre-installation preparation:Before installing the Yaskawa CACR-HR03BAB11Y40 Servopack,thoroughly review the official Yaskawa user manual for the CACR-HR series.This manual provides detailed instructions,wiring diagrams,safety precautions,and environmental specifications.Ensure that all power to the control cabinet and associated machinery is completely disconnected and properly locked out and tagged out to prevent accidental energization.Verify that the chosen mounting location within the control panel adheres to Yaskawa’s specifications for ambient temperature(0 to+40°C),humidity(20%to 80%non-condensing),and vibration(15µm or below).Proper ventilation and clearance around the Servopack are crucial to prevent overheating.The CACR-HR03BAB11Y40 contains static-sensitive components;therefore,always handle it with appropriate electrostatic discharge(ESD)precautions,such as wearing an anti-static wrist strap and working on a grounded surface.Carefully mount the Servopack in its designated rack-mounted slot,ensuring it is securely fastened.Meticulously connect all power cables(main input power,motor power),encoder feedback cables,and I/O/control signal cables to their respective terminals,strictly following the wiring diagrams in the manual.Use shielded,twisted-pair cables for signal and encoder lines,and ensure proper grounding to minimize noise.Double-check all connections for tightness and correct polarity before restoring power to the system.

Maintenance recommendations:Regular and proactive maintenance of the Yaskawa CACR-HR03BAB11Y40 Servopack is essential for ensuring the long-term reliability and precise operation of your motion control system.Periodically conduct thorough visual inspections of the Servopack for any signs of physical damage,loose terminal connections,or discoloration that might indicate overheating.Ensure that the control cabinet environment remains clean and free from dust,dirt,and moisture,as accumulated contaminants can impede heat dissipation and lead to electronic component failure.Verify that proper airflow is maintained around the Servopack to prevent thermal stress;ensure cooling fans(if present)are operating correctly and not obstructed.Regularly inspect all wiring connected to the CACR-HR03BAB11Y40 for wear,fraying,or damage,and confirm that all connections are tight.Loose or corroded connections can cause intermittent operation or complete system failure.Monitor the Servopack’s status indicators(e.g.,LED alarms)and any connected HMI or control system for diagnostic messages or error codes.Promptly address any alarms according to the troubleshooting guide in the Yaskawa manual.While the CACR-HR series is robust,avoid unnecessary physical handling of the Servopack.Regularly back up the Servopack’s parameters and motor tuning settings,as this data is crucial for quick restoration in case of module replacement or a system anomaly.For any suspected internal faults,persistent errors that cannot be resolved,or if the module requires complex adjustments or firmware updates,it is highly recommended to consult Yaskawa technical support or a certified Yaskawa service center.Unauthorized repairs can compromise the module’s performance,potentially damage the system,and void product warranties.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953 SOLEMN COMMITMENT 1. For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay. 2. For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems. 3. For discontinued materials and equipment, we provide alternative models and equipment replacement process services. 4. For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free. 5. We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems. 6. Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour. 7. For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer. The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers. We supply directly from abroad, without middlemen, reducing the cost of use. There is really no middleman who can make a price difference! ! If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time. Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit. Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields! ABB 5SHY3545L0010/3BHB013088R0001 MOTOROLA MVME2434 MOTOROLA MVME2432 A-B 81001-450-53-R ABB PNI800 WOODWARD 9907-164 NI PXIE-4145 ABB CI871K01 3BSE056797R1 MOTOROLA MVME5500-0161 MOTOROLA MVME5500-0163 EMERSON MVME55006E-0163 GE DS200DCFBG1BJB ABB PPD113B01-10-150000 ABB PM904F 3BDH001002R0001 MOTOROLA MVME2400 FOXBORO H92A0K9V0H00 PIONEER MAGNETICS PM36218B-10P-1-8PH-J GE IC698CPE040-JP EMERSON MVME7100 ABB HPC800K02 ABB SYN5202-0277 ABB HPC800K02(含HC800模块、CP800模块、底座) MOTOROLA MVME5500 MOTOROLA MVME55006E-0163R GE IS215UCVEM09B AMAT 0090-76110 VME PCB ABB 5SHX2645L0002/3HB012961R0001 ABB AO2000-LS25 ABB PM865K01 3BSE031151R1 ABB 5SHX1445H0001 3BHL000391P0101 3BHB003230R0101 5SXE05-0152 KONGSBERG DPS112 GE VMIVME-7750 ABB AO2000-LS25 TRICON 4352B ABB PFSK152 TRICONEX 3009 MOOG D136-001-007 SCANde INTELLISCANDE14-405NM SCANLAB

Reviews

There are no reviews yet.