Application Scenarios:

In a large-scale petrochemical refinery,the Foxboro 823DP-D3S1NL2 was used to measure pressure differentials in various processing units.The transmitter’s high accuracy and fast response time ensured optimal operation of critical filtration and separation processes,significantly improving product quality and reducing downtime.Operators were able to monitor and adjust pressure differentials remotely,thanks to its HART protocol support.

In a power generation plant,the 823DP-D3S1NL2 was integrated into steam boiler systems,helping maintain safe pressure levels throughout the entire process.Its rugged design and wide operating range enabled reliable operation despite the high temperature and pressure conditions,minimizing operational risk and enhancing safety.

Main Parameters:

Main Parameters Value/Description

Product Model 823DP-D3S1NL2

Manufacturer Foxboro

Product Category Differential Pressure Transmitter

Pressure Range 0-2000 psi

Output Signal 4-20 mA

Accuracy±0.1%of Span

Power Supply 24V DC

Response Time≤1 second

Operating Temperature-40°C to 85°C

Material Stainless Steel,IP67

Installation Type Flange Mount

Communication Protocol HART Protocol

Technical Principles and Innovative Values:

Innovation Point 1:Advanced DSP Technology for precise and fast signal processing,ensuring real-time measurement accuracy.

Innovation Point 2:The differential pressure measurement capability makes the 823DP-D3S1NL2 ideal for applications requiring precise flow and level measurements in closed-loop systems.

Innovation Point 3:The transmitter features wide compatibility with standard industrial protocols like HART,ensuring seamless integration into existing process control systems.

Innovation Point 4:Rugged,all-weather design,built with stainless steel housing to withstand high pressures,extreme temperatures,and corrosive environments,ensuring long-lasting durability.

Application Cases and Industry Value:

1.Chemical Processing Industry:

In a chemical plant,the Foxboro 823DP-D3S1NL2 was deployed in the filtration system to monitor pressure differential across the filters.The accuracy and stability of the transmitter significantly reduced the need for manual monitoring,improving operational efficiency.Furthermore,its rugged design prevented wear and tear,allowing the plant to focus on maximizing production without worrying about frequent equipment failures.

2.Power Generation Industry:

A large-scale power plant faced challenges with maintaining consistent pressure readings in its steam boilers,leading to safety concerns and operational inefficiencies.By implementing the 823DP-D3S1NL2,the plant successfully ensured more precise pressure regulation,enhancing both safety and performance.The real-time monitoring capabilities of the transmitter allowed for predictive maintenance,preventing costly downtime and reducing maintenance expenses.

Related Product Combination Solutions:

Foxboro 833DP-D3S1NL2:A higher-performance model ideal for extreme pressure and temperature applications in high-risk environments.

Foxboro 822DP-S1S2NL2:A more compact version of the 823DP-D3S1NL2,designed for applications where space is limited but accuracy is still critical.

Foxboro 771DP Differential Pressure Transmitter:A cost-effective alternative for non-critical applications that require basic pressure differential measurement capabilities.

Foxboro 272H Pressure Transmitter:Complements the 823DP-D3S1NL2 by offering general pressure monitoring capabilities for lower-pressure systems in industrial automation setups.

Foxboro 272PS Pressure Switch:Designed for pressure on/off control,ideal for coupling with the 823DP-D3S1NL2 for enhanced system monitoring and control.

Installation,Maintenance,and Full-Cycle Support:

The Foxboro 823DP-D3S1NL2 is designed for quick and easy installation,featuring a flange-mounted design that simplifies mounting on pipes or process equipment.Its plug-and-play installation ensures minimal downtime during setup,making it a convenient option for both new and retrofitted systems.

Maintenance is straightforward,with easy-to-access calibration and diagnostic options for fast troubleshooting.The transmitter’s self-diagnostics feature alerts operators to potential issues before they cause system failure,ensuring ongoing reliability.

Foxboro provides full-cycle support,including installation assistance,regular maintenance schedules,and remote troubleshooting via HART communication.Their expert technical team offers rapid response times,ensuring your system stays operational with minimal disruption.The company’s dedicated spare parts supply chain ensures long-term support for the 823DP-D3S1NL2,guaranteeing optimal performance for years to come.

Contact us for a customized solution!

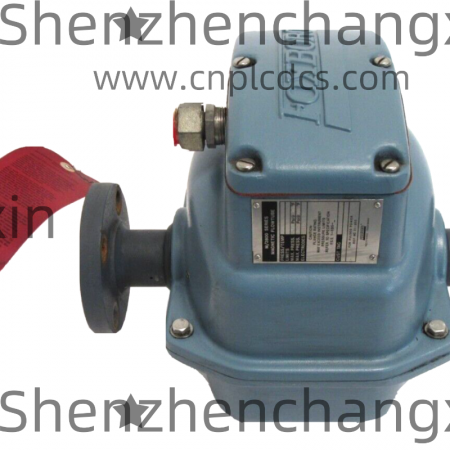

Foxboro 823DP-D3S1NL2 Differential Pressure Transmitter for Industrial Applications

Foxboro 823DP-D3S1NL2 Reliable Pressure Transmitter for Oil&Gas Industry

Precision Differential Pressure Measurement with Foxboro 823DP-D3S1NL2

Foxboro 823DP-D3S1NL2 Rugged Differential Pressure Transmitter for Harsh Environments

Foxboro 823DP-D3S1NL2 Pressure Transmitter with HART Protocol for Process Control

Foxboro 823DP-D3S1NL2 High-Performance Differential Pressure Transmitter for Chemical Plants

Foxboro 823DP-D3S1NL2 Robust Pressure Transmitter for Power Generation Systems

Foxboro 823DP-D3S1NL2 Reliable Differential Pressure Monitoring for Critical Applications

Foxboro 823DP-D3S1NL2 Advanced Differential Pressure Transmitter for Filtration Systems

Foxboro 823DP-D3S1NL2 Accurate Pressure Transmitter for Safe Industrial Operations

Reviews

There are no reviews yet.