Application Scenarios

At a Middle Eastern natural gas processing plant undergoing a partial DCS modernization, engineers needed to retain existing field wiring while upgrading control hardware to improve reliability. The FOXBORO FBM230 was selected to interface over 200 emergency shutdown (ESD) valve position feedbacks and motor run-status signals. Its wetted 24 VDC input design eliminated the need for external loop power supplies, and its built-in LED indicators per channel allowed technicians to verify field signal presence without opening panels—reducing troubleshooting time by 60%. Most critically, the FOXBORO FBM230’s compatibility with the legacy I/A Series network enabled a phased cutover without production interruption, proving indispensable in a facility where unplanned downtime costs exceed $ 2M per hour.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Wetted Input Architecture for Signal Integrity

Unlike dry-contact modules that rely on external power, the FOXBORO FBM230 actively sources 24 VDC to field devices, ensuring consistent voltage levels and reducing susceptibility to ground loops or induced noise—critical in high-voltage substations or motor control centers.

Innovation Point 2: Per-Channel Diagnostics Without External Tools

Each of the 16 channels features a front-panel LED that indicates real-time signal status (ON/OFF) and fault conditions (e.g., open wire). This allows operators to validate field device health during commissioning or maintenance without multimeters or system software—accelerating response times.

Innovation Point 3: Seamless Integration in Redundant DCS Topologies

When installed in a redundant FBM carrier (e.g., FBM207), the FOXBORO FBM230 supports automatic failover with zero data loss, ensuring continuous monitoring of safety-critical signals like fire/gas detectors or pump trip commands.

Innovation Point 4: Long-Term Lifecycle Support in Legacy Infrastructure

Despite being part of a mature DCS platform, the FOXBORO FBM230 remains in active supply under Schneider Electric’s long-term commitment, making it a cornerstone for brownfield sites that prioritize operational continuity over full system replacement.

Application Cases and Industry Value

In a U.S. nuclear power plant’s auxiliary feedwater system, the FOXBORO FBM230 monitors 16 critical valve position switches that confirm isolation during emergency cooldown sequences. Regulatory auditors praised the module’s deterministic response time (<10 ms) and channel isolation, which prevent fault propagation during electrical transients. Over a 12-year deployment, zero spurious trips were attributed to I/O failure—validating the FOXBORO FBM230’s role in safety-grade applications.

Similarly, in an Australian alumina refinery, dozens of FOXBORO FBM230 modules interface with conveyor belt misalignment and tear sensors. Their robust surge protection and conformal coating option have withstood years of dust, moisture, and EMI from nearby VFDs—reducing I/O card replacements by 90% compared to earlier non-isolated models.

Related Product Combination Solutions

FBM201 / FBM207: Carrier bases for FOXBORO FBM230—FBM207 enables redundant I/O configurations

FBM231: 16-channel discrete output module, complementary for control loops

FBM202: Analog input module (4–20 mA) for temperature/pressure signals in same system

FBM242: High-speed pulse counter module for flow or rotation measurement

I/A Series Workstation (e.g., WS2000): Engineering station for configuration and diagnostics

FOXCOM Fieldbus Cables: Shielded twisted-pair cables for reliable FBM-to-controller communication

FBM203: Thermocouple/mV input module for furnace or boiler monitoring

Schneider EcoStruxure Foxboro DCS: Modern evolution of I/A Series for new deployments

Installation, Maintenance, and Full-Cycle Support

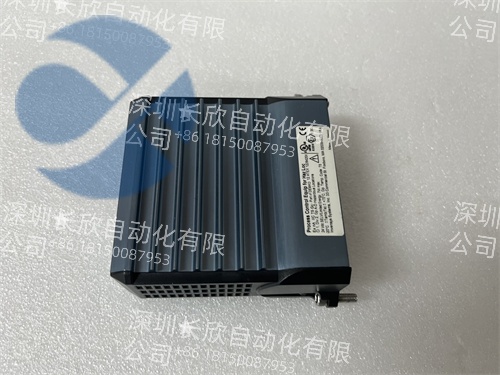

Installing the FOXBORO FBM230 requires only insertion into a compatible FBM carrier (e.g., FBM201 for simplex, FBM207 for redundant systems) and connection of field wires to the removable terminal block. No calibration or DIP switches are needed—configuration is handled entirely in the I/A Series engineering environment, where channel tagging, alarm limits, and diagnostic thresholds are defined. The module supports hot-swap in redundant setups, allowing replacement during operation without system shutdown.

Maintenance is simplified by front-accessible LEDs and self-diagnostics reported to the DCS operator console. In case of failure, the entire module can be replaced in under five minutes. Every FOXBORO FBM230 we supply is functionally tested, includes original firmware, and comes with a 24-month warranty. We also provide cross-reference support for obsolete variants and assist with migration planning to EcoStruxure platforms when future readiness becomes a priority.

Backed by global inventory and decades of Foxboro DCS expertise, we ensure your FOXBORO FBM230 performs reliably—from initial commissioning through decades of service in the world’s most critical industrial facilities.

Contact us for genuine units, technical documentation, or lifecycle extension strategies tailored to your DCS infrastructure.

Reviews

There are no reviews yet.