Application Scenarios:

Imagine a vast,integrated steel mill where consistency in power supply is non-negotiable for uninterrupted furnace operations and rolling processes.The mill relies on a large GE industrial gas turbine,with its control dictated by the robust Mark V Speedtronic system.The core challenge is real-time data acquisition from hundreds of sensors(temperatures,pressures,vibration,fuel flow)and precise command execution to actuators(valves,breakers,generators)across the complex turbine and its auxiliaries.A delay or error in processing this I/O data could lead to significant operational inefficiencies,quality deviations,or even hazardous conditions.This is where the GE DS200UCPBG5AFB truly shines.Functioning as a specialized I/O engine,it takes the raw signals from various Genius I/O modules,processes them locally with its onboard microprocessor,and efficiently communicates this processed data to the main Mark V controllers.This distributed intelligence ensures rapid response times,reduces the load on the central CPU,and enhances the overall system’s determinism and reliability.The GE DS200UCPBG5AFB is vital for maintaining the mill’s energy production efficiency and ensuring the safety and precision demanded by continuous industrial operations.

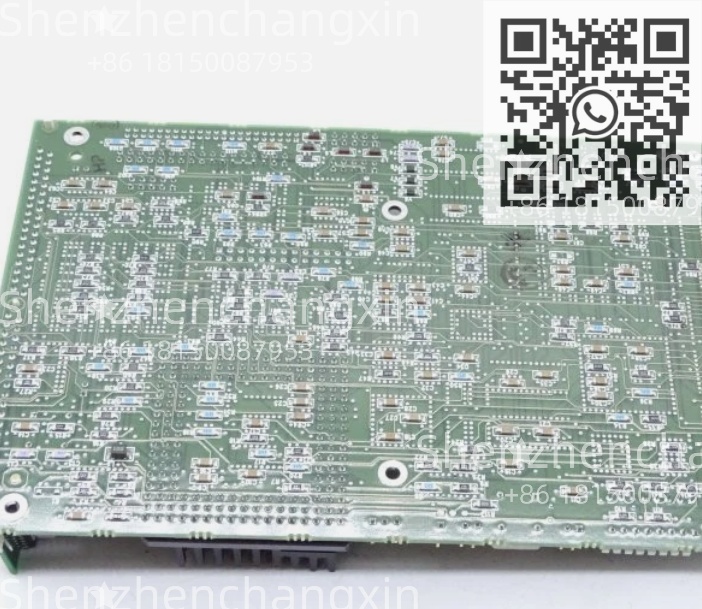

Parameter:

Technical Principles and Innovative Values:

The GE DS200UCPBG5AFB embodies a distributed processing philosophy,crucial for the robust and high-speed demands of turbine control:

Distributed I/O Processing:Unlike a purely centralized CPU,the GE DS200UCPBG5AFB acts as a dedicated I/O engine.It processes raw I/O signals locally using its onboard microprocessor before transmitting conditioned data to the main Mark V controllers.This significantly reduces the processing load on the central CPU,allowing it to focus on core control logic,and results in faster response times and improved system determinism for critical turbine parameters.

Configurability via Onboard Switches:The inclusion of a 7-switch block directly on the GE DS200UCPBG5AFB provides a powerful level of local configurability.This allows technicians to fine-tune the board’s behavior to specific site requirements or application nuances without complex software changes.This unique feature offers unparalleled flexibility and adaptability in field deployment,differentiating it from fixed-function I/O modules.

Robust and Modular Design:As a daughter card,the GE DS200UCPBG5AFB is designed for modularity,allowing for easier replacement and upgrades within the Mark V system.Its durable construction,including”Normal Coating”and specific artwork revisions(AFB),ensures resilience against industrial conditions.This modularity combined with robust build contributes to enhanced system maintainability and extended operational life for the entire turbine control platform.

Sustaining Legacy System Performance:The continued availability and functionality of boards like the GE DS200UCPBG5AFB are critical for the long-term viability of GE Mark V systems globally.By providing a reliable processing backbone for I/O,it enables power generators and industrial facilities to avoid costly complete system overhauls,ensuring their high-value turbine assets continue to operate efficiently and safely for decades.

Application Cases and Industry Value:

A prominent municipal power utility in Southeast Asia operates a fleet of aging but vital GE gas turbines for peak demand generation.One turbine experienced erratic behavior,characterized by inconsistent readings from various field instruments and occasional,unexplained trips.After extensive diagnostics,the issue was traced to an aging and intermittently failing GE DS200UCPBG5AFB board.Replacing the faulty board with a new surplus unit immediately restored the integrity of the I/O data flow.The turbine’s control system regained its precise and predictable response,eliminating the erratic behavior and significantly reducing unplanned outages.The utility reported a notable improvement in operational efficiency and a substantial decrease in maintenance costs related to false alarms and troubleshooting.This case powerfully demonstrates how investing in high-quality replacement components like the GE DS200UCPBG5AFB directly contributes to maximizing uptime,enhancing production safety by ensuring accurate control,and extracting prolonged value from multi-million dollar turbine investments.

Related Product Combination Solutions:

The GE DS200UCPBG5AFB is an integral processing component within the GE Mark V Speedtronic ecosystem,working closely with various other modules to achieve comprehensive turbine control:

GE DS200STCAG1A(Turbine Communication Board):Often works directly with the GE DS200UCPBG5AFB as its”IONET master,”conditioning signals from connectors and writing to the I/O Engine.

GE DS200PCCAG1A(Processor Control Card):The main Mark V CPU that communicates with and relies on the I/O processing capabilities of the GE DS200UCPBG5AFB.

GE DS200TCPSG1ARE(DC Input Power Supply Board):Provides the stable and regulated DC power supply that is essential for the reliable operation of the GE DS200UCPBG5AFB and other Mark V components.

GE DS200ADCIH1A(Genius Adapter Board):If the system utilizes Genius I/O,this board would interface the Genius network with the Mark V system,with the GE DS200UCPBG5AFB potentially processing the adapted data.

GE DS200LDCCH1A(LAN Daughter Card):Provides crucial network connectivity for diagnostics and external communication for the Mark V system,interacting with the processing capabilities of boards like the GE DS200UCPBG5AFB.

GE DS200TBQEG1A(Analog Termination Module):As an I/O engine,the GE DS200UCPBG5AFB would receive signals from various termination boards,including those handling analog inputs like the DS200TBQEG1A.

Installation,Maintenance,and Full-Cycle Support:

Installing the GE DS200UCPBG5AFB demands meticulous attention to safety and precision,given its central role in the Mark V control system.Before any installation or maintenance,ensure the entire GE Mark V cabinet and associated turbine control circuits are completely de-energized,strictly adhering to lockout/tagout procedures.As a plug-in daughter card,the GE DS200UCPBG5AFB requires careful alignment with its corresponding motherboard and the backplane during insertion to prevent damage to pins or connectors.It is highly recommended that installation and initial commissioning be performed by qualified technicians with in-depth knowledge of GE Mark V architecture,particularly regarding board configuration via the onboard switches,which must be set according to specific site requirements before powering on.

Routine maintenance for the GE DS200UCPBG5AFB primarily involves ensuring an optimal operating environment within the Mark V control cabinet.Regular visual inspections for dust accumulation,signs of moisture,or any discoloration indicating overheating are crucial.Proper ventilation within the cabinet is paramount for the longevity of the GE DS200UCPBG5AFB and other electronic components.While the board is designed for high reliability,any intermittent I/O issues or control anomalies should prompt a thorough diagnostic check using specialized GE tools,as problems with the UCPB can impact overall system performance.The onboard switches should only be adjusted by authorized personnel following documented procedures.

We are committed to providing comprehensive technical support for your GE DS200UCPBG5AFB and all related GE Mark V components.From assisting with accurate product identification and sourcing genuine,tested replacement parts to offering expert guidance on maintenance best practices,our unwavering commitment is to minimize your operational downtime and ensure the sustained,reliable performance of your critical turbine control systems.Our support ensures the longevity and peak efficiency of your existing high-value assets.

Sources

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

Reviews

There are no reviews yet.