Application Scenarios:

In a large water treatment plant, a critical 3000 HP raw water pump motor represents a significant capital asset. A sudden failure due to an overload, phase imbalance, or bearing overheating could halt the entire treatment process, causing regulatory non-compliance and service disruption. The GE 531X305NTBAPG1 relay is installed in the motor’s feeder circuit. It continuously monitors current, voltage, and (with optional RTDs) temperature. If a sustained overload condition is detected—indicating a blockage in the pump—the relay’s inverse-time thermal model calculates the motor’s heating and will trip the breaker before the motor insulation is damaged. Furthermore, its Modbus RTU communication allows the plant’s SCADA system to monitor real-time motor current, power, and trip status remotely. Before such intelligent relays, operators relied on basic overload heaters that couldn’t communicate or provide diagnostic data, leading to unexpected failures and reactive maintenance. The 531X305NTBAPG1 enables predictive health monitoring, allowing maintenance to be scheduled during a planned outage, thereby maximizing motor lifespan and system availability.

Parameter:

Main Parameters Value/Description

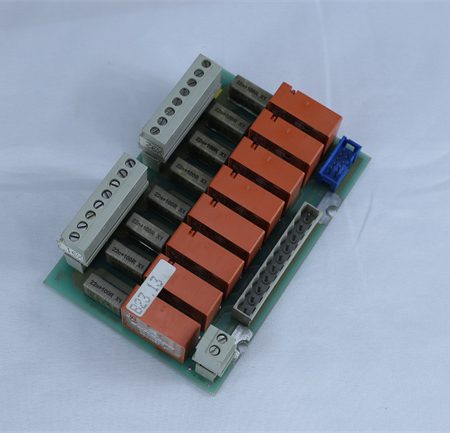

Product Model 531X305NTBAPG1 (Also F31X305NTBAPG1. Code: MRP375547)

Manufacturer GE Multilin (General Electric)

Product Category Motor Management Relay / Protection Relay

Series/Platform GE Multilin 369

Key Protection Functions Overload (Thermal Model), Unbalance, Jam, Locked Rotor, Short Circuit, Ground Fault, Undercurrent, Multiple Starts

Inputs 3 Phase CT Inputs, Ground CT Input, 3 Phase VT Inputs (optional)

Control Power Supply 24-240 VAC/VDC (wide range)

Communication Modbus RTU (RS485 serial port)

Digital I/O Multiple Form-C Relay Outputs, Discrete Inputs

Motor Data Storage Stores motor nameplate data, load profiles, and event history

Key Feature Combines advanced protection with motor management and communication

Technical Principles and Innovative Values:

Innovation Point 1: Motor Thermal Model Protection. Unlike simple overcurrent relays, the GE 531X305NTBAPG1 uses a sophisticated digital replica of the motor’s thermal characteristics. It incorporates motor data (FLA, service factor, thermal capacity) and continuously calculates heat buildup based on measured current and pre-programmed thermal curves. This model accounts for cooling times and accurately protects against overloads, locked rotor, and excessive starts, preventing insulation degradation and extending motor life far more effectively than traditional bimetallic heaters.

Innovation Point 2: Integrated Diagnostics and Metering. The relay is a rich source of operational data. It acts as a multi-meter, providing real-time values for current, voltage, power, power factor, and energy. It also logs critical information like starts per hour, total run time, and thermal capacity used. This data, accessible via the front interface or Modbus RTU, transforms the relay from a simple protective device into a diagnostic tool, enabling condition-based monitoring and predictive maintenance strategies.

Innovation Point 3: Flexible Logic and Control Functions. The 531X305NTBAPG1 includes configurable logic (FlexLogic™ equivalent in the 369 series), allowing users to create custom control schemes using the relay’s internal data and I/O. For example, a sequence can be programmed to start a lubrication pump (via a relay output) for 30 seconds before enabling the main motor starter. This programmability reduces the need for external PLCs for simple sequences, lowering system cost and complexity.

Application Cases and Industry Value:

Case Study: Mining Conveyor Drive System Retrofit. A mining operation experienced repeated failures of the drive motors on its main overland conveyor, leading to massive production losses. The root cause was difficult-to-detect high-resistance connections in aging contactors, causing phase unbalance and overheating. The existing thermal-magnetic breakers provided inadequate protection. The solution was to retrofit each motor starter with a GE 531X305NTBAPG1 relay. The relay was configured with sensitive unbalance protection, which tripped the motor if the current imbalance exceeded 5% for a sustained period. Additionally, its start and stall protection prevented damage during conveyor jam events. The relay’s communication capability integrated all conveyor motor data into the site’s control room. The maintenance team could now see which motor was approaching its thermal limit and proactively investigate. The result was a complete elimination of motor burnouts on that conveyor within the first year, saving an estimated $250.000 in motor repairs and 120 hours of lost production time.

Related Product Combination Solutions:

A complete motor protection solution using the GE 531X305NTBAPG1 involves several key components. It receives current signals from Current Transformers (CTs) like GE DRU-1000 series, and voltage from Potential Transformers (PTs). For motor bearing and winding temperature monitoring, it can interface with Resistance Temperature Detector (RTD) probes. The relay’s output contacts directly control the coil of the Motor Starter or Circuit Breaker. It communicates to the plant DCS or SCADA via its RS485 port, often through a Modbus to Ethernet gateway. It is mounted in a switchgear compartment, and its settings are configured using specialized software like GE Multilin EnerVista 369 Setup. Complementary protection for the entire feeder might include a GE Multilin 750 Feeder Management Relay.

Installation, Maintenance, and Full-Cycle Support:

Installation of the GE 531X305NTBAPG1 should be performed by a qualified electrician. Key steps include correct sizing and wiring of the CTs and PTs, ensuring proper polarity, and applying the correct control power. The most critical setup phase involves programming the relay via its front keypad or software. This includes entering the motor’s exact nameplate data (FLA, service factor) and carefully setting all protection thresholds (overload, unbalance, etc.) to match the specific motor and driven equipment. Incorrect settings can lead to nuisance trips or, worse, failure to protect.

Routine maintenance involves verifying the relay’s display readings against known system measurements (e.g., using a clamp-on ammeter) and reviewing the stored event log for any alarms or trips. The relay itself is a solid-state device with no user-serviceable internal parts. Our full-cycle support ensures reliable operation. We supply guaranteed genuine GE 531X305NTBAPG1 relays. We offer configuration file backup services and can assist with initial setup guidance to ensure your motor protection is optimized. For legacy system support, we can help confirm compatibility with existing CTs and control schemes. Each unit is backed by a warranty, and we provide access to technical documentation to support your team.

Contact us for a customized motor protection solution and to ensure you have the right GE Multilin relay for your critical assets.

-450x375.jpg)

Reviews

There are no reviews yet.