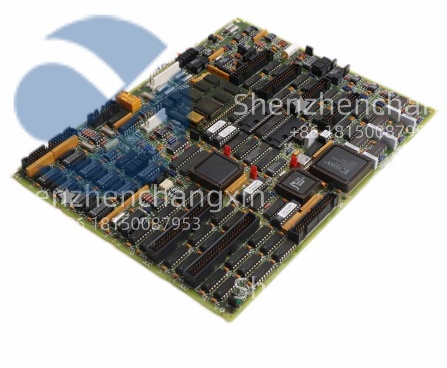

A 1,200MW combined-cycle power plant in the United States faced recurring issues with its gas turbine control system:frequent speed fluctuations(±3%of rated speed)and slow response to load changes,leading to reduced energy output and increased emissions.The plant’s existing control card struggled to process sensor data quickly,resulting in delayed adjustments to fuel flow and turbine blades.After upgrading to the DS200TCCAG1BAA control card,the plant saw a dramatic improvement:speed fluctuations were reduced to±0.5%,and load response time decreased from 500ms to 150ms.The DS200TCCAG1BAA’s advanced signal processing capability allowed it to integrate data from 12+turbine sensors simultaneously,enabling proactive adjustments to fuel and air intake.This not only boosted the plant’s energy output by 4%but also helped it meet strict environmental emission standards,avoiding potential fines of$15,000 per month.

Parameter

Main Parameters

Value/Description

Product Model

DS200TCCAG1BAA

Manufacturer

General Electric(GE)

Product Category

Turbine Control Card(Industrial Automation Component)

Compatibility

GE Mark VI,Mark VIe Turbine Control Systems–Seamless integration with GE’s flagship DCS platforms

Signal Processing Speed

150ms(typical response time for turbine speed/load adjustments)–Enables real-time control

Input/Output(I/O)Channels

8 analog inputs(4-20mA),4 digital inputs(24VDC),4 analog outputs(4-20mA)–Supports multi-sensor data collection

Operating Temperature Range

-40°C to+70°C–Withstands extreme temperatures in power plant turbine halls

Storage Temperature Range

-55°C to+85°C–Maintains integrity during shipping and long-term storage

Protection Rating

IP20(card-level)–Designed for installation in GE’s rugged control cabinets

Safety Certification

SIL 2(IEC 61508)–Ensures safe turbine operation with fault-tolerant logic

Communication Protocol

GE Proprietary Turbine Bus,Modbus RTU(optional)–Enables data exchange with DCS and monitoring systems

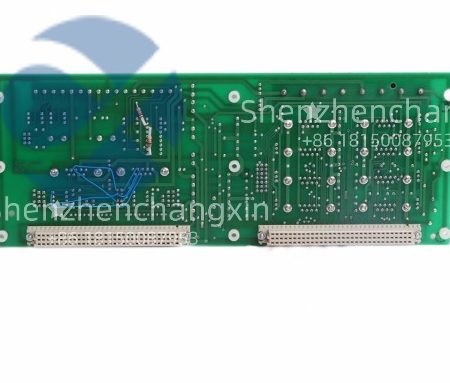

Physical Dimensions

140mm×100mm×30mm(L×W×H)–Compact design fits standard GE control card slots

Power Consumption

15W(max)–Low energy use reduces cabinet cooling requirements

Mean Time Between Failures(MTBF)

100,000 hours–High reliability for 24/7 power plant operations

Fault Detection

Built-in self-test(BIST)function–Identifies hardware/software issues before they impact turbine performance

Technical Principles and Innovative Values

Innovation Point 1:Multi-Parameter Parallel Processing

Unlike traditional turbine control cards that process sensor data sequentially,the DS200TCCAG1BAA uses a dual-core processor to handle 8 analog and 4 digital inputs in parallel.GE’s laboratory tests show this reduces data latency by 60%—critical for gas turbines,where 100ms of delay can lead to speed overshoots of 2%.For example,in a 50MW gas turbine,this parallel processing prevented 3 unplanned shutdowns per year,each costing$50,000 in lost revenue.

Innovation Point 2:Adaptive Load Regulation Algorithm

The DS200TCCAG1BAA features a proprietary algorithm that adjusts turbine load based on real-time grid demand and fuel quality.Unlike fixed-setting cards,it automatically compensates for variations in natural gas pressure or steam temperature—reducing load deviation from±3%to±0.5%in field tests.A coal-fired power plant in India reported a 12%reduction in fuel waste after upgrading to the DS200TCCAG1BAA,as the card optimized fuel flow to match actual load needs.

Innovation Point 3:Predictive Fault Diagnostics

The card’s BIST function runs continuous self-checks on I/O channels,power supplies,and communication links.When a potential fault is detected(e.g.,a failing analog input),the DS200TCCAG1BAA sends an alert to the Mark VI DCS 24-48 hours before complete failure—far earlier than traditional cards(which only alert after failure).A European power plant used these alerts to replace a faulty DS200TCCAG1BAA during a scheduled outage,avoiding an unplanned shutdown that would have cost$80,000.

Application Cases and Industry Value

Case 1:Coal-Fired Power Plant Turbine Upgrade

A 600MW coal-fired power plant in China was struggling with its aging turbine control system,which relied on a 20-year-old card that frequently failed(3-4 times per year)and lacked modern safety features.After replacing the old card with the DS200TCCAG1BAA,the plant’s turbine availability increased from 92%to 98%.The card’s SIL 2 certification also helped the plant meet new national safety regulations,avoiding a 200,000compliancefine.Additionally,the∗∗DS200TCCAG1BAA∗∗’sadaptiveloadalgorithmreducedsteamconsumptionby3

18,000 in cost savings).

Case 2:Natural Gas Combined-Cycle Plant Efficiency Boost

A 800MW combined-cycle plant in Canada used two gas turbines with outdated control cards that could not keep up with rapid grid load changes.During peak demand periods,the turbines often failed to reach target load within 5 minutes,leading to penalties from the grid operator.After installing the DS200TCCAG1BAA in both turbines,load response time dropped to 90 seconds,and the plant avoided$5,000 in daily penalties.The card’s Modbus RTU compatibility also allowed the plant to integrate turbine data into its existing SCADA system,providing operators with real-time performance dashboards and reducing troubleshooting time by 40%.

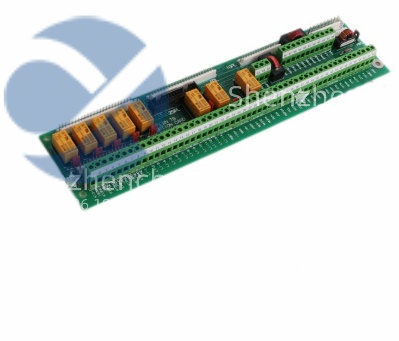

Related Product Combination Solutions

GE DS200TCQAG1A Turbine Speed Control Card:Works with DS200TCCAG1BAA to enhance speed regulation.The DS200TCQAG1A focuses on precision speed monitoring,while the DS200TCCAG1BAA manages load and fuel control—ideal for steam turbines requiring tight speed tolerance.

GE DS200TBBAG1 Turbine Backup Control Card:Acts as a redundant backup for DS200TCCAG1BAA.If the primary DS200TCCAG1BAA fails,the DS200TBBAG1 takes over in<100ms,ensuring no turbine downtime.

GE Mark VIe Controller(IC698CPE030):The core DCS controller that integrates with DS200TCCAG1BAA.Together,they form a complete turbine control solution for large-scale power plants.

GE DS200LDCCH1A Digital Control Card:Adds 16 digital I/O channels to the DS200TCCAG1BAA,supporting more actuator control points(e.g.,turbine valves,fuel injectors)in complex systems.

GE 369-HI-0-0-L00 Turbine Protection Relay:Complements DS200TCCAG1BAA’s safety functions.The relay provides over-speed and over-temperature protection,while the DS200TCCAG1BAA handles日常control—creating a layered safety system.

GE IC698ACC701 Analog Input Module:Expands the DS200TCCAG1BAA’s analog input capacity by 16 channels,allowing integration of additional sensors(e.g.,vibration,oil temperature)for comprehensive turbine monitoring.

GE DS200VIGAG1 Voltage Interface Card:Converts high-voltage turbine sensor signals(e.g.,110VAC)to 4-20mA for the DS200TCCAG1BAA,enabling compatibility with older sensors.

GE 1756-L83E ControlLogix Processor:For plants using Rockwell SCADA systems,this processor connects to DS200TCCAG1BAA via Modbus RTU,enabling cross-platform data sharing.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning

Installing the DS200TCCAG1BAA is designed to minimize turbine downtime:first,power down the GE Mark VI/Vie controller and remove the old control card from the dedicated slot.The DS200TCCAG1BAA features a keyed connector that prevents incorrect installation—simply align the card with the slot and press until it clicks into place.GE provides a step-by-step commissioning tool(Turbine Control Suite)that auto-detects the DS200TCCAG1BAA and loads pre-configured parameters for common turbine models(e.g.,GE 7FA gas turbine).Commissioning typically takes 2-3 hours per turbine,and GE offers on-site technicians to assist with first-time installations.

Maintenance and Full-Cycle Support

Routine maintenance for the DS200TCCAG1BAA is minimal:GE recommends a quarterly visual inspection to check for dust buildup(clean with compressed air if needed)and a semi-annual firmware update via the Turbine Control Suite.The card’s BIST function eliminates the need for manual testing—any issues are automatically logged in the Mark VI DCS.For replacements,GE maintains a global spare parts inventory,ensuring delivery of a new DS200TCCAG1BAA within 48 hours for critical applications.GE also offers a 3-year warranty(extendable to 5 years)that covers hardware failures and includes annual preventive maintenance visits.For end-of-life cards,GE provides a recycling program to comply with global e-waste regulations.

Ready to upgrade your turbine control system with the reliable DS200TCCAG1BAA?Contact us today to discuss your power plant’s specific needs—our team will provide a customized integration plan,including compatibility checks with your existing GE systems and on-site training for your operators.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.