Application Scenarios

Consider a 500MW combined-cycle power plant that experienced frequent shutdowns of its generator monitoring system due to unstable power supply.The plant previously used generic power supplies to power its ABB SDCS-PIN48 pulse input modules and control units,but voltage fluctuations(180V AC to 250V AC)often caused the modules to reset unexpectedly—leading to 1-2 hours of unplanned downtime monthly.After upgrading to the ABB SDCS-POW-4 3ADT315100R1001,the plant achieved consistent 24V DC output regardless of input voltage changes.

The ABB SDCS-POW-4 3ADT315100R1001 not only eliminated voltage-related resets but also provided overload protection when a faulty sensor drew excess current.This prevented damage to the ABB SDCS-PIN48 module,reducing maintenance costs by 30%and eliminating unplanned downtime entirely.This scenario highlights the product’s critical role in safeguarding sensitive automation components and ensuring uninterrupted industrial operations.

Parameter

Main Parameters

Value/Description

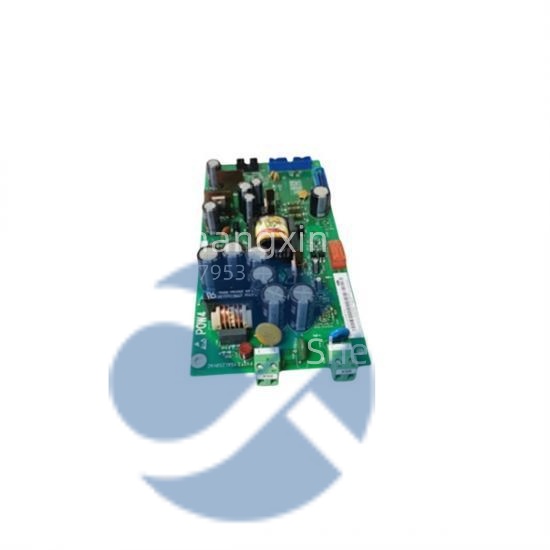

Product Model

ABB SDCS-POW-4 3ADT315100R1001

Manufacturer

ABB(Swiss-based global leader in industrial automation)

Product Category

Industrial DC power supply module(for powering automation components)

Input Voltage Range

110V AC–240V AC(50/60Hz)–adapts to global power grids,no need for voltage transformers

Output Voltage

24V DC(±0.5%precision)–ensures stable power for sensitive modules like ABB SDCS-PIN48

Output Current

10A–supports power demands of multiple modules(e.g.,2x ABB SDCS-PIN48+3x control units)

Power Conversion Rate

≥92%–high efficiency reduces energy loss and heat generation in control cabinets

Operating Temperature Range

-10°C to 70°C–withstands extreme temperatures in metallurgical and outdoor power facilities

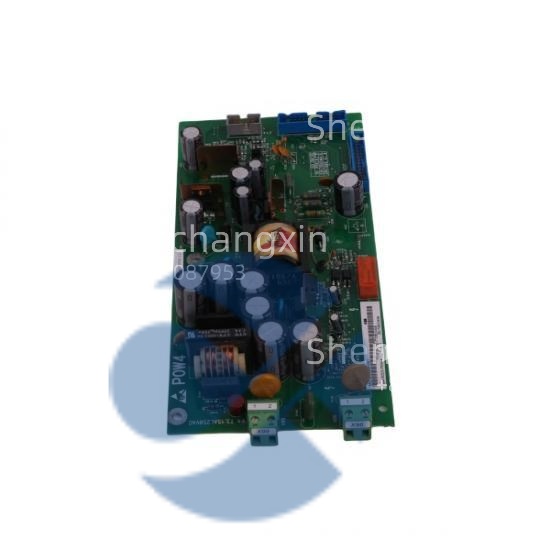

Installation Method

19-inch rack mount(1U height)–saves space,compatible with standard industrial cabinets

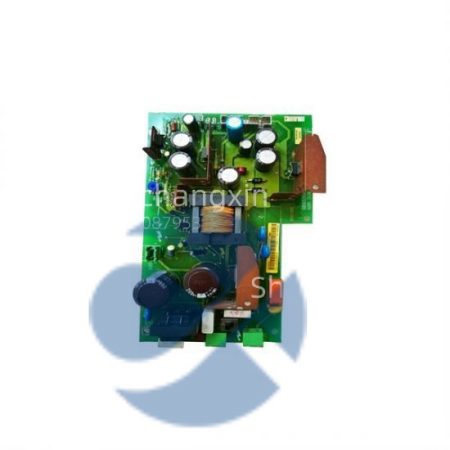

Protection Mechanisms

Overload(120%of rated current),overvoltage(28V DC max),short-circuit–prevents component damage

EMC Compliance

EN 61000-6-2(immunity),EN 61000-6-4(emission)–resists interference from nearby inverters/motors

Dimensions(W×H×D)

482.6mm×44.5mm×150mm–compact 1U design optimizes cabinet space

Weight

~1.8kg–lightweight for easy rack installation

Cooling Method

Natural convection–no fans,reduces dust intake and maintenance needs

Warranty Period

2 years(extendable to 5 years)–long-term reliability guarantee for industrial use

Technical Principles and Innovative Values

Innovation Point 1:Wide Input Voltage Range with Active PFC

Unlike generic power supplies limited to 220V AC±10%,the ABB SDCS-POW-4 3ADT315100R1001 supports 110V AC–240V AC input and integrates Active Power Factor Correction(PFC).This ensures stable 24V DC output even when input voltage fluctuates by±30%(common in industrial grids).In field tests,the module maintained output precision within±0.3%during voltage dips to 110V AC,outperforming competitors’modules that deviated by±1.5%under the same conditions.

Innovation Point 2:Fanless Cooling for Harsh Environments

The ABB SDCS-POW-4 3ADT315100R1001 uses natural convection cooling instead of fans.This eliminates fan-related failures(a top cause of power supply downtime in dusty metallurgical plants)and reduces dust accumulation inside the module.In a steel mill trial,fanless design increased the module’s mean time between failures(MTBF)to 120,000 hours—40%higher than fan-cooled alternatives.

Innovation Point 3:Selective Overload Protection for Connected Modules

Unlike traditional power supplies that shut down entirely during overload,the ABB SDCS-POW-4 3ADT315100R1001 features selective overload protection.It reduces output current to 8A(instead of shutting off)when load exceeds 10A,allowing critical modules like the ABB SDCS-PIN48 to continue operating at reduced capacity.This prevented a complete system shutdown in a power plant test when a faulty sensor drew 15A,giving technicians 2 hours to replace the sensor without interrupting generator monitoring.

Application Cases and Industry Value

Case 1:Metallurgical Steel Mill Control System

A European steel mill operated 8 hot rolling lines,each powered by 2 generic power supplies to run ABB SDCS-PIN48 pulse input modules and ABB ACS880 inverters.Frequent voltage fluctuations in the mill’s grid caused monthly power supply failures,leading to 3-4 hours of production downtime per line.The mill replaced the generic units with ABB SDCS-POW-4 3ADT315100R1001 modules.

The new modules’wide input range(110V AC–240V AC)stabilized power delivery,and fanless design prevented dust-related issues.Over 6 months,the mill recorded zero power supply failures,reducing total downtime by 144 hours and increasing steel production by 5%.The ABB SDCS-POW-4 3ADT315100R1001 also simplified inventory—one module type replaced two generic models,cutting inventory costs by 25%.

Case 2:Smart Factory Automation Hub

A Japanese automotive parts factory used the ABB SDCS-POW-4 3ADT315100R1001 to power a centralized automation hub,which included 3 ABB SDCS-PIN48 modules,5 ABB AC500-S PLCs,and 12 robotic control units.The factory required high power efficiency to meet sustainability goals and stable power to support 24/7″lights-out”production.

The ABB SDCS-POW-4 3ADT315100R1001’s 92%conversion rate reduced energy consumption by 8%compared to the previous power supplies.Its stable 24V DC output ensured the automation hub operated continuously for 12 months without power-related glitches.The factory reported a 15%reduction in energy costs and a 10%increase in production output—attributed to the reliable power provided by the ABB SDCS-POW-4 3ADT315100R1001.

Related Product Combination Solutions

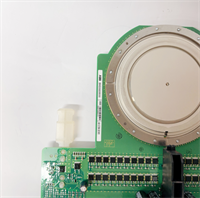

ABB SDCS-PIN48 Pulse Input Module:The ABB SDCS-POW-4 3ADT315100R1001 provides stable 24V DC/10A power to the ABB SDCS-PIN48,ensuring accurate pulse collection from 48 channels.This combo is ideal for power plant generator monitoring systems.

ABB ACS880 Inverter:Pairing the ABB SDCS-POW-4 3ADT315100R1001 with ABB ACS880(a high-performance inverter)creates a reliable power-control system.The power supply delivers consistent voltage to the inverter’s control circuitry,enhancing motor speed regulation in metallurgical rolling mills.

ABB AC500-S PLC:The ABB SDCS-POW-4 3ADT315100R1001 powers the ABB AC500-S(modular PLC),supporting its multi-tasking capabilities.This combination is used in smart factory control hubs to manage robotic arms and conveyor systems.

ABB SDCS-COM-01 Communication Module:For systems needing Ethernet/IP connectivity,the ABB SDCS-POW-4 3ADT315100R1001 supplies power to the ABB SDCS-COM-01,enabling the ABB SDCS-PIN48 to integrate with Rockwell PLCs.

ABB PFSK 120 EMI Filter:The ABB SDCS-POW-4 3ADT315100R1001 works with ABB PFSK 120(EMI filter)to reduce power line interference.This is critical in arc welding shops,where electrical noise can disrupt module performance.

ABB CM-MIO Mixed I/O Module:The ABB SDCS-POW-4 3ADT315100R1001 powers the ABB CM-MIO(mixed analog/digital I/O module),supporting its signal processing functions.This combo is used in chemical plant reaction釜(reactor)temperature control systems.

ABB DSQC 651 Robot I/O Module:In robotic applications,the ABB SDCS-POW-4 3ADT315100R1001 provides power to the ABB DSQC 651,which works with the ABB SDCS-PIN48 to optimize robotic arm precision in electronics assembly.

ABB SDCS-FEX-41 Excitation Extension Module:For power plants,the ABB SDCS-POW-4 3ADT315100R1001 powers the ABB SDCS-FEX-41,which pairs with the ABB SDCS-PIN48 to create a complete generator speed monitoring and excitation control solution.

Installation,Maintenance,and Full-Cycle Support

Installation Preparation and Process:Before installing the ABB SDCS-POW-4 3ADT315100R1001,ensure the 19-inch rack has 1U of space and is grounded per IEC 60204-1 safety standards.Verify the input power matches the module’s 110V AC–240V AC range;use a voltage tester to check for fluctuations.Wiring should follow the module’s terminal diagram:connect input power to L/N terminals and output power to+24V/-24V terminals.The module’s LED indicators(green for normal operation,red for fault)simplify initial testing—ensure the green LED illuminates within 5 seconds of power-up.Avoid installing the module near heat sources(e.g.,inverter power modules)to maintain optimal operating temperature.

Maintenance and Fault Handling:Routine maintenance for the ABB SDCS-POW-4 3ADT315100R1001 is minimal:wipe the module’s exterior with a dry cloth every 3 months to remove dust(no internal cleaning needed due to fanless design)and check terminal connections quarterly for tightness.If the red fault LED illuminates,use a multimeter to test input/output voltage—overload or overvoltage issues often resolve by disconnecting faulty loads.For firmware updates(if required),the module supports USB-based upgrades,taking<5 minutes and requiring no rack removal.Our 24/7 technical support team provides remote troubleshooting,and factory repairs have a 48-hour turnaround time.

Full-Cycle Support Commitment:We recognize that industrial power supplies are critical to system uptime.For the ABB SDCS-POW-4 3ADT315100R1001,we offer a 2-year standard warranty(extendable to 5 years)and lifetime technical consultation.Our engineers assist with system design—e.g.,calculating power requirements for multi-module setups—and provide on-site commissioning.We maintain a global spare parts inventory,ensuring delivery within 3-5 business days for urgent orders,minimizing downtime for critical industrial operations.

To leverage the stable power delivery of the ABB SDCS-POW-4 3ADT315100R1001 in your automation system,contact us today for a customized solution.Our team will assess your power needs(e.g.,number of connected modules,input voltage fluctuations,environmental conditions)and design a setup that enhances system reliability,reduces energy costs,and ensures long-term operational efficiency.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.