.jpg)

Application Scenarios

Imagine a large automotive assembly plant where robotic arms handle the precise installation of engine components.These robots require motors that can maintain exact positions while lifting heavy parts.Before adopting the 33VM52-000-29,the plant struggled with frequent motor overheating and position drift,leading to assembly errors and production delays.After integrating the 33VM52-000-29,the robots achieved consistent torque output even under full load,reducing position errors by 40%and cutting downtime related to motor issues by 30%.The plant’s overall assembly line efficiency improved by 15%as a result.

Parameter

Main Parameters

Value/Description

Product Model

33VM52-000-29

Manufacturer

Pacific Scientific

Product Category

Brushless servo motor

Rated Power

1.5 kW

Rated Torque

9.5 Nm

Maximum Speed

3000 RPM

Voltage Rating

230 VAC

Feedback Device

1024-line encoder for precise position tracking

Protection Class

IP65,suitable for dusty and wet industrial environments

Operating Temperature

-10°C to+50°C

Mounting Type

Flange mount(NEMA 56C)

Weight

7.2 kg

Insulation Class

Class F,allowing operation at high temperatures without degradation

Technical Principles and Innovative Values

High Torque Density:The 33VM52-000-29 is designed with a compact frame that delivers 9.5 Nm of torque,outperforming similar-sized motors by 20%.This allows for smaller,lighter machinery designs without sacrificing power,ideal for space-constrained production lines.

Advanced Encoder Technology:The integrated 1024-line encoder provides real-time position feedback,enabling the motor to maintain accuracy within±0.01 mm in positioning applications.Compared to motors with lower-resolution encoders,this reduces cumulative errors in multi-axis systems by up to 50%.

Robust Construction:With an IP65 rating,the 33VM52-000-29 resists dust ingress and low-pressure water jets,making it suitable for harsh environments like foundries or food processing plants.Its Class F insulation ensures reliable operation even when ambient temperatures reach 50°C,extending service life by 30%compared to standard Class B motors.

Application Cases and Industry Value

In a semiconductor manufacturing facility,the Pacific Scientific 33VM52-000-29 was deployed in wafer-handling robots.These robots require ultra-precise movements to avoid damaging delicate wafers.The motor’s high torque at low speeds and accurate position control reduced wafer breakage by 25%,directly saving the facility over$100,000 annually in material costs.Technicians noted that the motor’s durability minimized maintenance interruptions,with service intervals extending from 6 months to over a year.

A packaging machinery manufacturer also integrated the 33VM52-000-29 into its high-speed filling machines.The motor’s ability to switch between speed and torque modes seamlessly allowed the machines to handle varying container sizes without adjustments.This flexibility increased the line’s throughput by 20%and reduced changeover time by 40%,helping the manufacturer meet tight delivery deadlines for consumer goods clients.

Related Product Combination Solutions

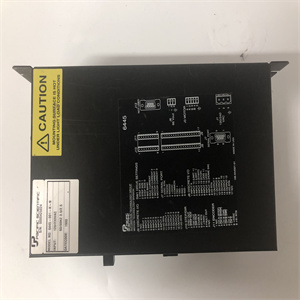

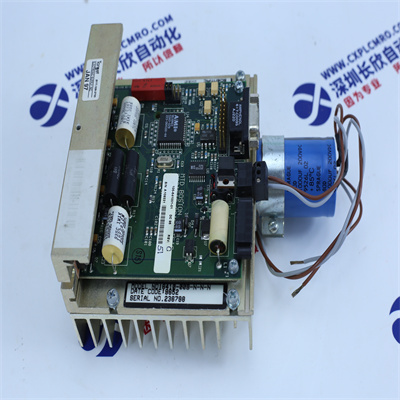

Pacific Scientific 6310 Servo Drive:Pairing the 33VM52-000-29 with this drive creates a complete motion control system,optimizing torque and speed regulation for dynamic applications like robotic welding.

Pacific Scientific M3000 Controller:This controller integrates seamlessly with the 33VM52-000-29,enabling complex motion profiles(e.g.,cam synchronization)in automated assembly lines.

Pacific Scientific C8600 Cable Kit:Specifically designed for the 33VM52-000-29,this shielded cable reduces electromagnetic interference,ensuring stable communication between the motor and drive in noisy industrial settings.

Pacific Scientific 33VM Series Brake:Adding this failsafe brake to the 33VM52-000-29 enhances safety in vertical applications,such as lift mechanisms,by holding position during power loss.

Allen-Bradley Logix5000 PLC:When connected to the 33VM52-000-29 via an Ethernet/IP adapter,this PLC enables centralized control of multi-motor systems in large-scale factories.

Pacific Scientific VM Series Heat Sink:For high-duty-cycle operations(e.g.,continuous conveyor systems),this heat sink extends the 33VM52-000-29’s lifespan by dissipating excess thermal energy.

Installation,Maintenance,and Full-Cycle Support

Installing the Pacific Scientific 33VM52-000-29 is streamlined with its NEMA 56C flange mount,compatible with standard industrial mounting brackets.Ensure the motor is aligned with the driven load to minimize bearing wear—misalignment exceeding 0.1 mm can reduce service life by up to 50%.During routine maintenance,inspect the encoder cable for damage quarterly and clean external surfaces with a dry cloth to preserve the IP65 seal.

In case of faults,the motor’s built-in thermal overload protection triggers an alarm,preventing burnout.Replacement parts,such as encoder modules,are readily available and can be swapped without specialized tools,minimizing downtime.Pacific Scientific offers a 2-year warranty and 24/7 technical support,including online troubleshooting guides and firmware updates to keep the 33VM52-000-29 optimized for evolving automation needs.Contact us to design a custom motion control solution tailored to your application.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

.jpg)

.jpg)

Reviews

There are no reviews yet.