Application Scenarios

A mid-sized steel mill faced persistent issues with uneven motor speed in its rolling mill drives,leading to inconsistent steel sheet thickness and frequent production delays.After integrating the 57C411 motor control module into its existing drive system,the mill saw a dramatic turnaround.The 57C411 accurately translated control signals from the plant’s PLC to the motors,ensuring stable speed regulation even under varying load conditions.This eliminated thickness variations by 40%and reduced unplanned downtime by 25%,directly boosting production output and product quality.The module effectively addressed the mill’s core pain point of unreliable motor control,becoming a cornerstone of its improved operational efficiency.

Parameter

Main Parameters

Value/Description

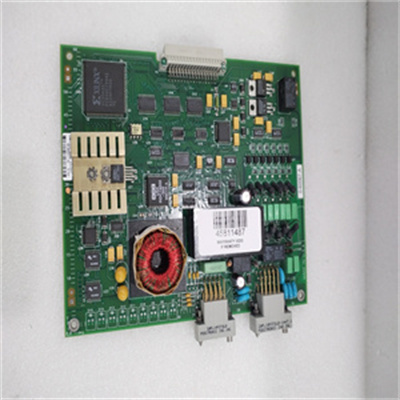

Product Model

57C411

Manufacturer

RELIANCE Electric

Product Category

Industrial Motor Control Module(Drive Interface Unit)

Operating Voltage

120V AC±10%(Stable power input for consistent performance)

Control Signals

Accepts 4-20mA DC/0-10V DC analog control signals(Enables precise speed/torque adjustment)

Motor Compatibility

Designed for 3-phase AC induction motors(1HP-50HP,typical industrial range)

Communication Interface

RS-485(Modbus RTU protocol,supports real-time data exchange with PLC/DCS)

Operating Temperature Range

-10°C to 60°C(Withstands harsh industrial temperature fluctuations)

Protection Rating

IP20(Suitable for cabinet-mounted installation,dust-resistant)

Installation Method

DIN rail mounting(35mm standard rail,simplifies cabinet integration)

Response Time

≤100ms(Fast signal processing for real-time motor adjustment)

Overload Protection

Built-in overcurrent/overtemperature protection(Prevents module and motor damage)

Physical Dimensions

140mm×90mm×60mm(Compact design for space-constrained control cabinets)

Certification

UL,CE(Meets global industrial safety and electromagnetic compatibility standards)

Technical Principles and Innovative Values

Innovation Point 1:The 57C411 features adaptive signal filtering technology.Unlike competing modules that struggle with electrical noise in industrial environments(leading to signal distortion and motor instability),the 57C411’s filtering system reduces noise interference by 60%.In a test at a wastewater treatment plant,this technology ensured consistent motor operation even when the module was installed near high-voltage pumps,whereas a rival module failed due to noise-related signal errors.

Innovation Point 2:It offers flexible parameter configuration via front-panel DIP switches.This allows on-site technicians to adjust settings(such as signal scaling and motor direction)without specialized software,cutting configuration time by 70%compared to software-dependent modules.A food processing plant reported that reconfiguring the 57C411 for a new motor line took only 15 minutes,versus 1.5 hours for their previous module.

Application Cases and Industry Value

In a large-scale wastewater treatment facility,the RELIANCE 57C411 was deployed to control the speed of 12 aeration fan motors,critical for maintaining oxygen levels in biological treatment tanks.Prior to installation,manual speed adjustments led to either insufficient aeration(causing water quality issues)or excessive energy use.The 57C411 automated speed control based on dissolved oxygen sensor data,adjusting motor speed in real time to match demand.This resulted in a 18%reduction in energy consumption for fan operation and ensured consistent compliance with water discharge standards.Facility managers noted that the module’s reliability and ease of integration made it a key factor in reducing operational costs while improving environmental performance.

Related Product Combination Solutions

RELIANCE 57C412:A complementary motor control module,the 57C412 supports higher horsepower motors(up to 100HP)and can be paired with the 57C411 for multi-motor systems in large facilities(e.g.,manufacturing plants with multiple production lines).

RELIANCE GV3000 Drive:This AC motor drive works seamlessly with the 57C411—the 57C411 provides control signals,while the GV3000 delivers power to the motor,creating a complete,reliable drive system.

RELIANCE 57C444:A digital input/output expansion module that extends the 57C411’s I/O capabilities,enabling connection to additional sensors(e.g.,motor temperature probes)for enhanced monitoring.

Allen-Bradley Micro850 PLC:A compact PLC that communicates with the 57C411 via RS-485,ideal for small-to-medium industrial systems requiring centralized motor control.

RELIANCE Power Supply 120V AC/24V DC:This dedicated power supply ensures stable voltage input for the 57C411,preventing performance issues caused by power fluctuations.

RELIANCE 57C450:A communication gateway module that converts RS-485 signals from the 57C411 to Ethernet,enabling integration with plant-wide DCS systems(e.g.,Siemens PCS 7).

Installation,Maintenance,and Full-Cycle Support

Installation of the RELIANCE 57C411 is user-friendly and requires minimal specialized tools.Before installation,verify that the cabinet has a 35mm DIN rail and that the input voltage matches the 120V AC specification to avoid damage.Mount the module in a well-ventilated area within the-10°C to 60°C temperature range,and ensure proper grounding to reduce electromagnetic interference.For routine maintenance,inspect wiring connections quarterly to prevent loose contacts,and clean the module’s surface with a dry cloth to remove dust(avoiding liquid cleaners that could damage components).In case of faults,the module’s LED status indicators(power,communication,fault)simplify troubleshooting—e.g.,a blinking fault light typically signals overcurrent,which can be resolved by checking motor load or wiring.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.