Application Scenarios

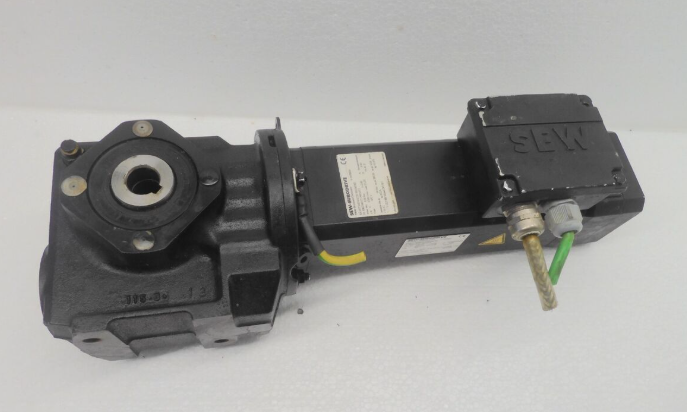

In a bulk material handling facility, a troughed belt conveyor is responsible for moving tons of aggregate per hour. The conveyor’s drive system requires high starting torque to overcome inertia and move the loaded belt, and it must operate reliably in dusty conditions. The SEW MXA81A-100-503-00 gearmotor is perfectly suited for this role. Mounted directly to the conveyor’s drive pulley shaft, its robust helical-worm design provides the necessary high torque in a compact footprint. The right-angle output allows for a space-saving installation where the motor is oriented parallel to the conveyor frame. Its sealed housing protects the internal gearing from abrasive dust, ensuring long-term, maintenance-free operation. This reliable drive solution keeps the conveyor running continuously, directly supporting the plant’s production throughput.

Parameter

Annotation: The part number is a configuration code. MX = Helical-Worm Gearmotor series. 81 = Frame size. A = Design variant. 100-503-00 = The precise ratio and mechanical configuration. The exact ratio (e.g., 17.76:1. 24.76:1) and output shaft dimensions are defined by this suffix and must be confirmed with SEW’s technical documentation or a configurator.

Technical Principles and Innovative Values

The SEW MXA81A-100-503-00 leverages a two-stage gear design that marries the strengths of two different gear types for optimal performance in demanding applications.

Innovation Point 1: Combined Efficiency and High-Ratio Capability. The first stage uses helical gears, which are highly efficient and transmit power smoothly with minimal noise. The second stage employs a worm gear, which provides a very high reduction ratio in a single stage and allows for a right-angle shaft orientation. This combination offers a better balance of efficiency and high reduction capability compared to a double-worm design, which would be less efficient, or a pure helical design, which would require more stages for the same ratio.

Innovation Point 2: Compact Right-Angle Design and Potential Self-Locking. The 90-degree output allows the motor to be mounted parallel to the machine frame, saving significant space compared to an in-line gearmotor that extends the drive line. Furthermore, for certain gear ratios, the worm gear stage provides a self-locking effect. This means the output shaft cannot back-drive the input, acting as a mechanical brake. This is a critical safety and functional feature for applications like inclined conveyors or lifts, preventing the load from causing the system to reverse in the event of power loss.

Innovation Point 3: Modularity and Standardized Design. The MXA series is part of SEW’s modular system. The gear unit is designed to accept a wide range of standard IEC motors (from SEW or other brands) via a standardized input flange. This allows for immense flexibility in creating a complete drive solution tailored to exact power, speed, and duty cycle requirements, simplifying design, procurement, and maintenance.

Application Cases and Industry Value

Case Study: Reliable Drive for a Wastewater Treatment Screw Conveyor

A municipal wastewater plant uses a large screw conveyor (archimedes screw) to lift screened debris from the water channel. The environment is corrosive, wet, and the load is uneven. The drive system, an SEW MXA81A-100-503-00 gearmotor coupled to a weatherproof motor, was selected for its robustness and the inherent self-locking characteristic of its worm gear stage. This self-locking feature is crucial: it prevents the column of water and debris in the screw from forcing the mechanism to reverse when the motor stops, which could cause damage and safety hazards. The unit’s sealed housing has withstood the harsh environment for over 7 years with only routine oil changes, demonstrating exceptional reliability and reducing maintenance costs in a critical public service infrastructure.

Case Study: Space-Saving Agitator Drive in a Chemical Mixing Tank

A chemical processing plant needed to retrofit an agitator into an existing tank with very limited space above the tank opening. A traditional in-line gearmotor would not fit. The engineering team chose an SEW MXA81A-100-503-00 for its compact, right-angle profile. They mounted a flange-mounted motor horizontally, allowing the entire drive assembly to fit within the tight spatial constraints. The helical-worm gear provided the necessary high torque at low output speed required for mixing viscous fluids. The solution eliminated the need for costly structural modifications to the tank, saved significant installation time, and provided a reliable drive that has operated for years with minimal maintenance, ensuring consistent product quality.

Related Product Combination Solutions

SEW DR Motor (e.g., DRN series): A standard IEC AC motor that would be flange-mounted directly to the input of the MXA81A-100-503-00 gear unit to form a complete gearmotor.

SEW Movidrive Frequency Inverter: A variable frequency drive that could be used to control the motor attached to the MXA81A, enabling variable speed control of the conveyor, mixer, or other driven machine for process optimization.

Torque Arm and Bushings (e.g., SEW TAR, SAF/FAB Bushings): If configured as a shaft-mounted reducer, the MXA81A would require a torque arm reaction kit and bushings to mount it securely onto the driven shaft of the machine.

Backstop or Holdback Brake: While the worm gear may offer self-locking, for critical applications like inclined conveyors, an additional mechanical backstop is often installed on the MXA81A’s output shaft as a redundant safety device to prevent rollback.

Motor Mounting Flange (e.g., SEW IEC Adapter): The specific adapter flange that connects the chosen motor to the gear unit’s input housing, ensuring perfect alignment.

Coupling or Belt Drive Components: Depending on the design, the output shaft of the MXA81A may connect via a chain coupling, gear coupling, or a belt and pulley system to the final driven machine.

SEW Load Torque Monitoring Device: An optional sensor that can be integrated to monitor the output torque of the gear unit, providing data for predictive maintenance or process control.

Installation, Maintenance, and Full-Cycle Support

Installation of the SEW MXA81A-100-503-00 requires proper alignment. If foot-mounted, the unit must be securely bolted to a level, rigid baseplate, and the connected motor must be aligned to it. If shaft-mounted, the unit slides onto the driven shaft, and the torque arm must be firmly anchored to absorb the reaction force. The most critical step is ensuring the output shaft is correctly coupled to the load, avoiding any radial or axial misalignment that can cause premature bearing or seal failure. Input motor alignment is equally vital.

Maintenance is straightforward but essential. The primary task is regular monitoring and changing of the gear oil according to SEW’s specifications (type, viscosity, and change interval based on operating temperature and duty cycle). Regularly check for oil leaks, unusual noise, or excessive temperature rise. Input and output shaft seals should be inspected. Bearing re-greasing intervals, if applicable, must be followed. Our full-cycle support for the MXA81A includes providing detailed assembly drawings and installation manuals, assisting with correct motor selection and ratio verification, supplying the correct grade of gear oil and spare seals, and offering expert troubleshooting support for any operational issues. We help ensure your gear drive is installed correctly and maintained for maximum service life.

For durable, right-angle power transmission in demanding environments, trust in proven gear technology. Contact us for technical data sheets, ratio decoding, and sourcing for your SEW-EURODRIVE MXA81A-100-503-00 gear unit and compatible motors.

Reviews

There are no reviews yet.