.jpg)

Description:

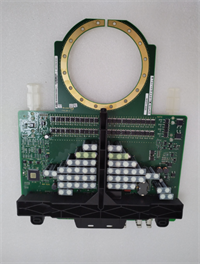

The ABB TP857 (3BSE030192R1) is a high-integrity, redundant-capable terminal baseplate designed for ABB’s S800 I/O modules within the AC 800M and 800xA Distributed Control System (DCS) architecture. It serves as the physical and electrical foundation for redundant analog and digital I/O channels, enabling seamless hot-swap maintenance and continuous signal availability in safety-critical or high-availability process environments.

Engineered for harsh industrial conditions, the TP857 supports dual independent power feeds, built-in diagnostics, and robust field wiring interfaces—making it essential for applications where sensor or actuator failure could trigger production loss, safety incidents, or environmental risk.

Application Scenarios:

At a Middle Eastern ethylene cracker facility, a single failed temperature input once caused an emergency shutdown of a $ 200M reactor train due to non-redundant I/O. After upgrading critical loops to ABB TP857 (3BSE030192R1) baseplates paired with redundant AI810 modules, engineers achieved true 1oo2 (one-out-of-two) voting on furnace tube temperatures. During a subsequent thermocouple failure, the system automatically switched to the healthy channel without triggering alarms—allowing production to continue uninterrupted. This transformation highlights how the TP857 turns vulnerable single-point measurements into resilient, decision-grade signals in extreme process environments.

Technical Principles and Innovative Values:

• Innovation Point 1: True Dual-Channel Isolation – The TP857 provides galvanically separated A and B signal paths from field terminal to I/O module pins, preventing common-mode failures—a key requirement for SIL2 safety loops per IEC 61508.

• Innovation Point 2: Passive Switchover Without Logic Delay – Unlike software-based redundancy, the TP857 uses hardware-level relay or solid-state switching to reroute signals within milliseconds of a module or power fault—ensuring zero control interruption.

• Innovation Point 3: Integrated Surge & EMI Protection – Built-in TVS diodes and filtering on all field terminals protect sensitive electronics from lightning-induced transients and VFD noise, reducing nuisance trips in electrically noisy plants.

• Innovation Point 4: Unified Diagnostics in 800xA – Channel health, power status, and module presence are reported directly to the 800xA asset structure, enabling predictive maintenance and reducing mean time to repair (MTTR) by up to 50%.

Application Cases and Industry Value:

A North American nuclear auxiliary cooling system required redundant level monitoring for spent fuel pools under NRC regulatory oversight. By deploying ABB TP857 (3BSE030192R1) baseplates with dual AI810 modules, the plant achieved fail-operational measurement integrity. During a scheduled test simulating a module failure, the system maintained accurate level indication and logged the event automatically—satisfying stringent NRC audit requirements. Plant engineers now use the TP857’s diagnostic data to schedule I/O replacements during planned outages, eliminating unplanned work orders. This case proves the TP857’s role not just in reliability, but in regulatory compliance and operational discipline.

Related Product Combination Solutions:

• AI810: Redundant analog input module designed specifically for TP857 dual-channel operation.

• TU850: Standard non-redundant baseplate; TP857 is its high-availability counterpart.

• PM891: Redundant CPU that pairs with TP857-based I/O for full-system fault tolerance.

• SA811: Redundant power supply that feeds dual 24 VDC rails to TP857 units.

• 800xA Asset Optimization: Software that visualizes TP857 channel health and predicts failures.

• CI854A: PROFIBUS communication module linking TP857 I/O stations to remote controllers.

• ABB FieldCare: Device management tool that validates I/O calibration through TP857 paths.

• Redundant I/O Kit (RK-TP857): Official bundle including sync cables, labeling, and mounting guides.

Installation, Maintenance, and Full-Cycle Support:

Installing the TP857 begins with securing it to a DIN rail and connecting two independent 24 VDC power sources to PWR A and PWR B terminals. Field wires are routed through shielded cables with grounds bonded at one end, then terminated using torque-controlled screwdrivers to prevent loosening. Redundant I/O modules snap into place with audible click confirmation.

For maintenance, the hot-swap design allows technicians to replace a faulty module while the process runs—simply unlock the old unit and insert the new one. The TP857’s LEDs instantly confirm power status and module recognition. Our support includes redundancy validation, wiring audits, and lifecycle planning (including obsolescence alerts). Every unit undergoes functional testing of both channels, surge immunity checks, and thermal cycling before shipment.

Contact us for a customized solution that integrates the ABB TP857 (3BSE030192R1) as the bedrock of your next high-integrity I/O system—with certified redundancy, regulatory-ready diagnostics, and full engineering support from concept to commissioning.

.jpg)

.jpg)

Reviews

There are no reviews yet.