Application Scenarios

At a large automotive stamping facility in Ohio,engineers faced recurring failures in their legacy relay-based control panels due to vibration and high switching cycles.The system required frequent maintenance and caused unplanned downtime.To modernize the operation,they replaced the relay clusters with IC660BBD024 sourcing output blocks.Each IC660BBD024 controlled 32 pneumatic valve solenoids on the press line,replacing over 50 individual relays per station.The solid-state outputs handled rapid cycling without wear,while the integrated LED indicators allowed technicians to instantly identify active or faulty circuits.Since deployment,the mean time between failures(MTBF)increased from 6 months to over 5 years.The IC660BBD024 not only reduced panel space by 70%but also cut maintenance labor by 80%,proving its value as a robust,high-performance alternative to traditional relay logic in demanding production environments.

Parameter

Main Parameters Value/Description

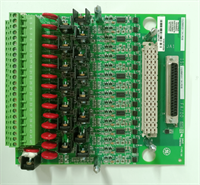

Product Model IC660BBD024

Manufacturer GE Fanuc Automation/GE Digital

Product Category Digital Output I/O Block

System Platform GE VersaMax ICS–part of the modular I/O ecosystem

Number of Outputs 32 Circuits–high channel density in compact form

Output Type Sourcing(Source)–supplies+24VDC to load(positive switching)

Load Voltage 24 VDC(nominal),18–32 VDC range–standard industrial voltage

Max Load Current 0.5 A per point,8.0 A total module–supports multiple small loads

Output Technology Solid-State Transistors(no moving parts)–long life,silent operation

Response Time<1 ms(On),<2 ms(Off)–fast switching for dynamic control

Isolation Optical isolation between field side and logic side–protects PLC from surges

LED Indication Green LED per output–visual status for each circuit(ON=lit)

Installation Method 35mm DIN Rail Mount–standard industrial mounting

Environmental Rating Operating Temp:-25°C to+60°C;Humidity:5%–95%non-condensing

Protection Class IP20–suitable for installation in control cabinets

Technical Principles and Innovative Values

Innovation Point 1:The IC660BBD024 delivers 32 sourcing outputs in a single compact module,drastically reducing cabinet space and wiring complexity compared to discrete relays or lower-density I/O.This high integration level is ideal for machine builders aiming to minimize footprint and assembly time.

Innovation Point 2:Utilizing solid-state transistor outputs,the IC660BBD024 eliminates mechanical wear,arcing,and contact bounce associated with electromechanical relays.With an MTBF exceeding 100,000 hours,it ensures long-term reliability in high-cycle applications like packaging,assembly,and material handling.

Innovation Point 3:Each output features individual optical isolation,preventing fault propagation from one circuit to another.This design enhances system safety and simplifies troubleshooting—critical in complex automation cells where a single short circuit could otherwise disable an entire output bank.

Innovation Point 4:The IC660BBD024 supports hot-swap capability when used with a compatible VersaMax ICS baseplate and power backplane.Failed modules can be replaced without shutting down the entire system,minimizing production downtime and supporting predictive maintenance strategies.

Application Cases and Industry Value

In a pharmaceutical tablet press line,the IC660BBD024 was deployed to control 32 ejection solenoids and status indicators.The cleanroom environment demanded silent,spark-free operation—conditions where traditional relays were unsuitable.The IC660BBD024’s solid-state design met these requirements perfectly.Its fast response ensured precise timing during high-speed pressing cycles(up to 120 strokes/minute),while the LED indicators enabled rapid diagnostics during changeovers.Over three years of continuous operation,there were zero output failures.The plant engineering team credited the IC660BBD024 with improving machine availability and reducing spare parts inventory.

Another application involved a municipal water pumping station upgrading its control panel.The old relay-based system required weekly maintenance due to contact corrosion from humidity.Replacing it with IC660BBD024 modules eliminated this issue.The sourcing outputs reliably switched pump contactors and alarm horns,and the optical isolation protected the control system from ground loops.Operators reported a dramatic drop in false trips and maintenance calls—demonstrating how modern I/O blocks can enhance both reliability and operational efficiency in critical infrastructure.

Related Product Combination Solutions

IC660GBI023:Bus Interface Module–connects the IC660BBD024 to the PLC CPU via Genius or Profibus networks.

IC660BBP101:Terminal Baseplate–DIN rail mountable base that accepts IC660BBD024 and provides screw-terminal connectivity.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

Reviews

There are no reviews yet.