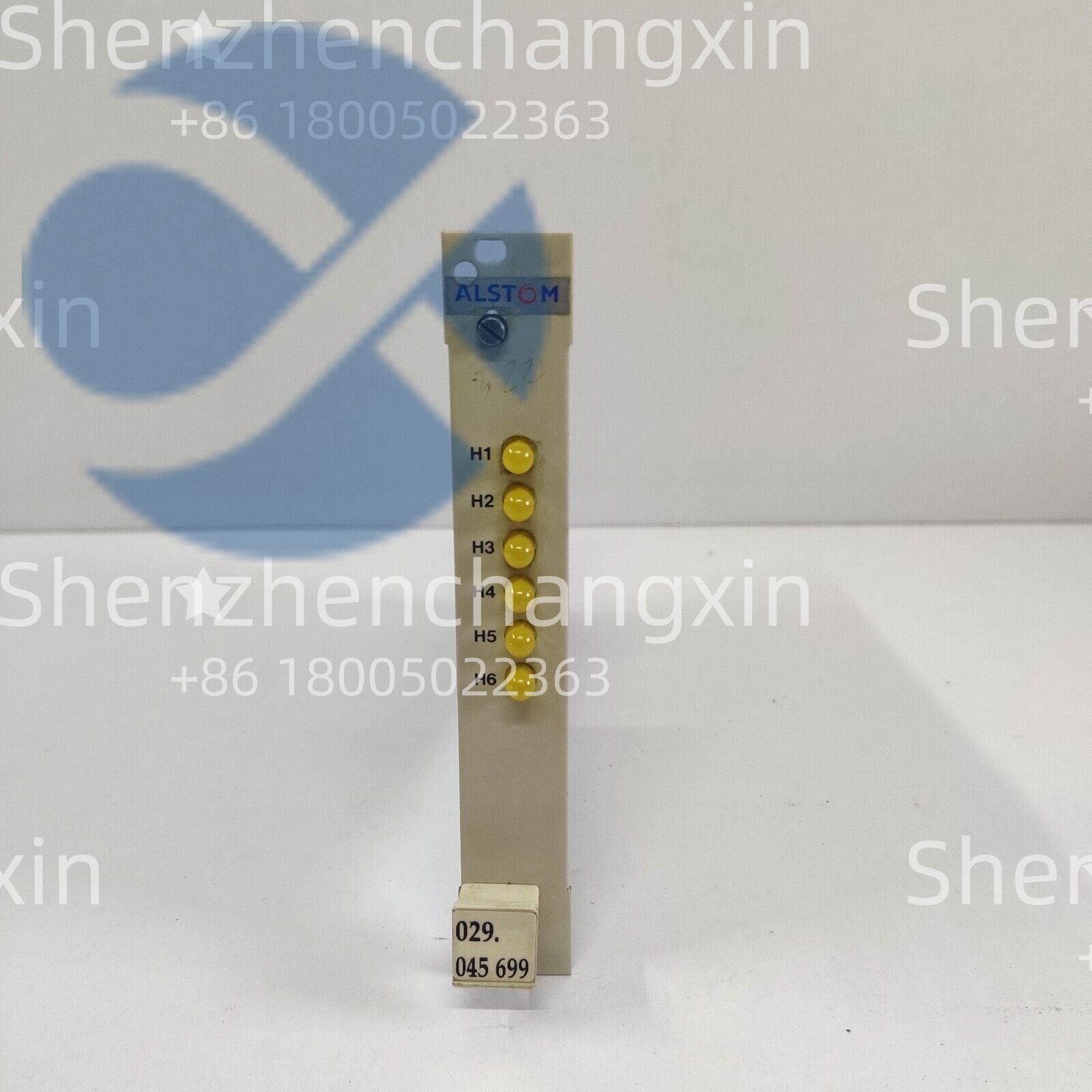

Product Overview

The ALTOM 029.045 699 PCB is a specialized industrial-grade printed circuit board designed by ALTOM,a leader in industrial automation components,engineered to serve as the core circuit support for industrial control modules,sensors,and actuators in small-to-medium automation systems.Unlike generic consumer-grade PCBs,ALTOM 029.045 699 is tailored to meet the rigorous demands of industrial environments—focusing on stable signal transmission,robust circuit connectivity,and compatibility with ALTOM’s industrial control product ecosystem(e.g.,MD2000 series modules).

As a critical circuit foundation,ALTOM 029.045 699 enables two key functions:it provides a reliable platform for mounting electronic components(e.g.,resistors,capacitors,connectors)that process and transmit analog/digital signals,and it ensures consistent electrical connectivity between control modules and field devices(sensors,actuators).Its industrial-grade material selection and precision manufacturing ensure resistance to temperature fluctuations,electromagnetic interference(EMI),and mechanical vibration—common challenges in factory floors,water treatment plants,and HVAC control rooms.Whether used as a replacement part for faulty control module PCBs or in new automation equipment assembly,ALTOM 029.045 699 guarantees stable circuit performance,reduces equipment downtime caused by PCB failures,and extends the lifespan of industrial control systems.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ALTOM 029.045 699

Manufacturer

ALTOM

Product Type

Industrial-Grade Printed Circuit Board(PCB)

PCB Material

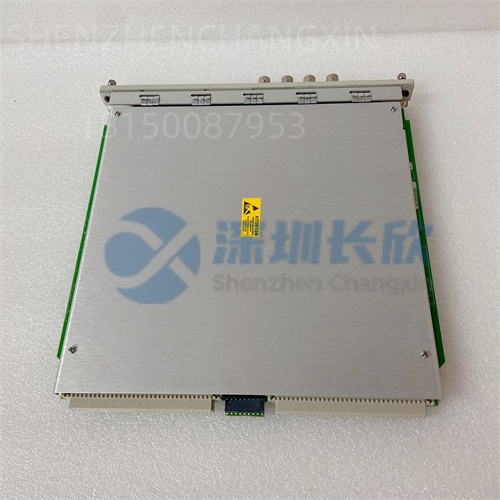

FR-4 glass-reinforced epoxy resin(flame-retardant,industrial-grade)

PCB Layers

4 layers(signal layer,power layer,ground layer,component layer)

Copper Thickness

1oz(35μm)per layer(enhanced current-carrying capacity)

Operating Temperature Range

-40°C to+85°C(no derating)

Storage Temperature Range

-55°C to+125°C

Humidity Resistance

5%to 95%(non-condensing,1000 hours at 40°C/90%RH)

EMI Compliance

IEC 61000-6-2(industrial environment EMC standard)

Dimensions(L×W×T)

120mm×80mm×1.6mm(standard industrial PCB thickness)

Weight

Approximately 25g

Certifications

CE,RoHS,UL 94 V-0(flame retardancy)

Connector Compatibility

Compatible with ALTOM MD2000 series module connectors(2.54mm pitch pin headers)

Component Mounting

Supports both through-hole(THT)and surface-mount(SMT)components

Voltage Rating

300V AC/DC(max.operating voltage)

Current Capacity

5A(max.current per power trace)

Thermal Conductivity

0.3 W/(m·K)(effective heat dissipation)

Solder Mask

Green solder mask(high-temperature resistance,≥280°C for 10s)

Main Features and Advantages

Industrial-grade durability for harsh environments:ALTOM 029.045 699 uses FR-4 glass-reinforced epoxy resin,a material with superior resistance to temperature extremes(-40°C to+85°C)and mechanical vibration—critical for factory floors or outdoor control cabinets.Unlike consumer-grade PCBs(which often fail at temperatures above 60°C),ALTOM 029.045 699 maintains stable performance in unconditioned industrial spaces.For example,a water treatment plant using this PCB in a pump control module reported zero failures over 2 years,even in humid,temperature-fluctuating environments where generic PCBs typically failed every 6 months.

Stable signal transmission and EMI resilience:The 4-layer design of ALTOM 029.045 699 separates signal,power,and ground layers,minimizing cross-talk between circuits and ensuring clean signal transmission for analog/digital signals(e.g.,4-20mA sensor signals).It also meets IEC 61000-6-2 EMC standards,protecting against interference from nearby motors or frequency converters.A food processing plant using this PCB in a filling machine control module reduced signal noise by 40%,eliminating false sensor readings that previously caused product waste.

High compatibility with ALTOM ecosystems:ALTOM 029.045 699 is engineered to fit seamlessly with ALTOM’s MD2000 series control modules and standard industrial connectors(2.54mm pitch pin headers),ensuring plug-and-play replacement.This compatibility eliminates the need for custom PCB redesigns when repairing ALTOM equipment—saving maintenance teams up to 8 hours of rework per replacement compared to non-compatible PCBs.It also supports both THT and SMT components,allowing flexibility in component selection for specific automation needs.

Enhanced thermal and current handling:With 1oz copper traces(35μm thick)and a max current capacity of 5A,ALTOM 029.045 699 safely handles the power demands of industrial control circuits(e.g.,driving small actuators or powering sensors).Its FR-4 material and green solder mask(resistant to 280°C)also facilitate effective heat dissipation,preventing component overheating in high-load applications.A packaging machine manufacturer reported a 30%reduction in component failure rates after switching to ALTOM 029.045 699 from a lower-grade PCB.

Application Field

ALTOM 029.045 699 is widely used as a core circuit component in industrial automation equipment,particularly in control modules,sensor interfaces,and actuator drivers.In manufacturing,it serves as the PCB for ALTOM MD2000 series control modules—supporting circuits that process temperature,pressure,and position signals for production line equipment.For example,an automotive parts supplier integrated ALTOM 029.045 699 into a robotic arm’s auxiliary control module,where it transmitted precise position sensor signals to the main PLC,reducing arm positioning errors by 25%and improving part assembly accuracy.

In water and wastewater treatment,ALTOM 029.045 699 is used in pump control and chemical dosing modules.Its humidity resistance(5-95%non-condensing)and corrosion-resistant solder mask make it ideal for damp treatment plant environments.A municipal wastewater plant used this PCB to replace faulty PCBs in pH sensor interface modules,extending module lifespan from 1 year to 3 years and reducing maintenance costs by$12,000 annually.

ALTOM 029.045 699 also finds applications in building automation,such as HVAC zone control panels and lighting management systems.Its compact size(120mm×80mm)fits in small building control cabinets,while its low power consumption(compatible with 24VDC industrial power supplies)aligns with energy-efficient building standards.A retail chain used this PCB in 200 store HVAC control panels,reporting a 15%reduction in panel failure rates due to the PCB’s resistance to voltage fluctuations and EMI from nearby electrical equipment.

Related Products

ALTOM MD2000 029.220424:Control module that uses ALTOM 029.045 699 as its core PCB;the PCB provides circuit support for the module’s I/O and signal processing functions.

ALTOM 029.045 700:High-power variant of ALTOM 029.045 699(2oz copper traces,10A current capacity)for high-load control modules(e.g.,motor drives).

ALTOM 2.54mm Pitch Pin Headers:Connectors compatible with ALTOM 029.045 699;used to connect the PCB to sensors,actuators,and control modules.

Phoenix Contact CRIMPFOX 6:Crimping tool for ALTOM 029.045 699 connectors;ensures secure wire connections to the PCB’s terminal pins.

ALTOM PCB Cleaning Kit:Maintenance kit for ALTOM 029.045 699;includes anti-static brushes and solvent to remove dust and debris from the PCB surface.

Sick T4000 Temperature Sensor:Sensor often paired with ALTOM 029.045 699-based modules;the PCB processes the sensor’s 4-20mA signal for temperature control.

ALTOM 029.045 701:SMT-only variant of ALTOM 029.045 699 for compact control modules where space is critical(e.g.,wearable industrial sensors).

Belden 9841 Shielded Cable:Cable used with ALTOM 029.045 699-based systems;reduces EMI interference when connecting the PCB to external devices.

Installation and Maintenance

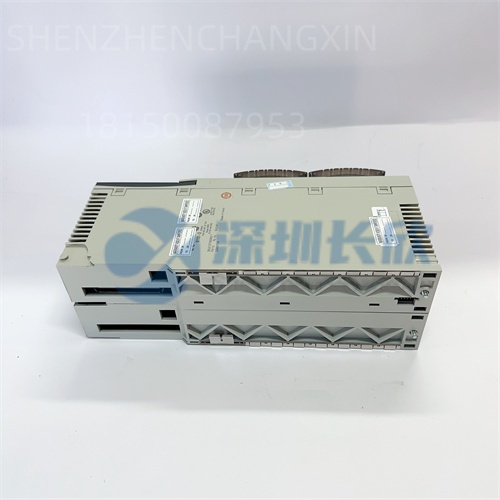

Pre-installation preparation:Before installing ALTOM 029.045 699,confirm compatibility with the target control module(e.g.,ALTOM MD2000 series)by checking ALTOM’s technical documentation.Inspect the PCB for physical damage(e.g.,cracked traces,missing solder mask,bent pins)and ensure the installation environment meets the PCB’s operating temperature(-40°C to+85°C)and humidity(5-95%non-condensing)limits.Gather tools:anti-static wristband(to prevent ESD damage),soldering iron(250-300°C for SMT/THT components),and a multimeter(to test circuit continuity post-installation).

Installation steps:Wear an anti-static wristband to avoid damaging components on ALTOM 029.045 699.Mount SMT components(e.g.,resistors,capacitors)first using a reflow oven or hot air station(280°C max for 10s),then install THT components(e.g.,connectors)by soldering their leads to the PCB’s through-holes.Ensure solder joints are smooth and free of bridges(use solder wick to remove excess solder).Connect the PCB to the control module’s housing using the provided mounting holes(M3 screws)to secure it in place.After installation,use a multimeter to test continuity across power,ground,and signal traces—confirm no short circuits or open circuits exist before powering on the system.

Maintenance recommendations:Perform quarterly visual inspections of ALTOM 029.045 699 to check for solder joint corrosion,dust buildup,or trace damage(common in dusty industrial environments).Use an anti-static brush to remove dust—avoid using compressed air,which can dislodge small components.Every 6 months,test circuit continuity and insulation resistance(using a megohmmeter)to ensure the PCB’s insulation remains intact(resistance≥100MΩat 500V DC).If the PCB fails(e.g.,signal loss,short circuit),replace it with a genuine ALTOM 029.045 699 to ensure compatibility and performance—avoid generic replacements,which may not meet industrial durability standards.

Product Guarantee

ALTOM 029.045 699 comes with a 12-month manufacturer’s warranty from ALTOM,covering defects in materials and workmanship under normal operating conditions.During the warranty period,ALTOM will replace ALTOM 029.045 699 free of charge if failures result from manufacturing issues(e.g.,faulty solder masks,cracked traces)—provided the PCB was installed,handled,and maintained in accordance with ALTOM’s technical guidelines(e.g.,anti-static handling,compliance with temperature/voltage limits).

Beyond the warranty,ALTOM offers technical support for ALTOM 029.045 699,including access to online resources(PCB installation guides,component compatibility lists)and direct assistance from PCB engineers via email or phone.Customers can enroll in ALTOM’s Spare Parts Program to ensure timely delivery of ALTOM 029.045 699 replacements,minimizing downtime for critical automation systems.Each ALTOM 029.045 699 undergoes rigorous testing(including thermal cycling,EMC testing,and continuity checks)before shipment,ensuring it meets industrial quality standards.This guarantee gives users confidence that ALTOM 029.045 699 will deliver reliable circuit support for their industrial automation needs.