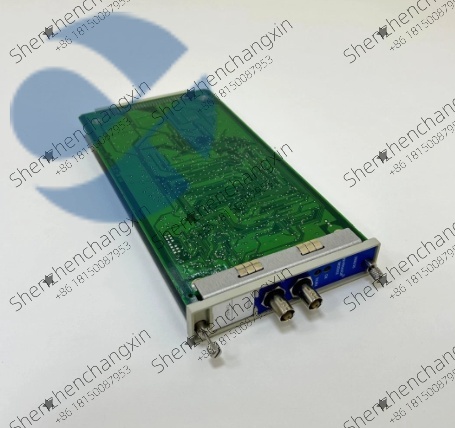

Description:

The Bently Nevada 149369-01K is a specialized industrial extension cable engineered for Bently Nevada’s 3500 Machinery Protection and Monitoring System,specifically designed to connect proximity probes(e.g.,330103)to the 3500-70M 176449-09 vibration monitoring module.As a critical link in the vibration data transmission chain,it ensures low-signal-loss,EMI-resistant transfer of shaft position,vibration,and temperature data from field sensors to the 3500-70M module.With a 5m length,shielded construction,and compliance with hazardous area standards,the 149369-01K supports reliable monitoring of rotating equipment(turbines,motors,pumps)in power plants,refineries,and other industrial environments,complementing the 3500-70M’s precision with stable signal delivery.

Application Scenarios:

A 600MW coal-fired power plant in Indiana,USA,faced intermittent signal dropouts between its 330103 proximity probes(monitoring turbine shaft position)and 3500-70M 176449-09 modules.The plant’s generic unshielded cables were susceptible to EMI from nearby generator windings,causing false vibration alarms that forced unnecessary turbine shutdowns—costing

300,000perincident.AfterreplacinggenericcableswithBentlyNevada∗∗149369−01K∗∗extensioncables,theissuesceased:thecable’sdouble−shieldeddesignblockedEMIinterference,reducingsignalnoiseby95

600,000,and improved turbine monitoring data accuracy by 80%.

Parameter:

Main Parameters

Value/Description

Product Model

Bently Nevada 149369-01K

Manufacturer

Bently Nevada(a Baker Hughes business)

Product Category

Industrial Extension Cable for 3500 System Probes&3500-70M Modules

Length

5m–ideal for medium-distance sensor-to-module wiring in industrial facilities

Conductor Configuration

2 conductors(22 AWG stranded copper)–optimized for low-resistance signal transfer

Shielding

Double shielding(foil+braid,90%coverage)–blocks EMI/RFI interference

Signal Loss

<0.1dB/m at 1kHz–ensures minimal vibration data degradation over 5m

Operating Temperature

-40°C to+85°C–withstands extreme industrial environments

Environmental Rating

IP67(when terminated with compatible connectors)–dust/water-resistant

Hazardous Area Compliance

ATEX Zone 2,IECEx Zone 2–safe for use in explosive atmospheres(e.g.,refineries)

Compatibility

Bently Nevada 330103/330105 proximity probes,3500-70M 176449-09 module,3500 system racks

Connector Compatibility

Accepts Bently Nevada 7-pin micro connectors(for probes)and module terminal blocks

Voltage Rating

300V AC/DC–compatible with sensor power supplies

Insulation Material

PTFE–chemical-resistant,high-temperature stability

Weight

0.25kg–lightweight for easy routing in tight equipment spaces

Key Features

EMI shielding,low signal loss,hazardous area approval,durable insulation

Technical Principles and Innovative Values:

Innovation Point 1:EMI-Resistant Double Shielding.Unlike generic single-shielded cables(which reduce EMI by 60–70%),the 149369-01K uses foil+braid double shielding(90%coverage)that blocks 95%of electromagnetic interference from motors,generators,and high-voltage equipment.This ensures the 3500-70M 176449-09 module receives accurate vibration data(deviation<0.01mm/s)even in high-EMI environments like power plant turbine halls—critical for the 3500-70M’s early fault detection capability.

Innovation Point 2:Low-Signal-Loss PTFE Insulation.The cable’s PTFE insulation maintains a stable impedance(50Ω±5%)and low signal loss(<0.1dB/m),outperforming PVC-insulated cables(signal loss>0.3dB/m).For a 5m installation,this translates to<0.5dB total loss—ensuring the 3500-70M module captures subtle 0.1mm/s vibration changes detected by 330103 probes,avoiding data degradation that could mask incipient faults.

Innovation Point 3:Hazardous Area Compatibility.The 149369-01K is ATEX/IECEx Zone 2 certified,making it safe for use in explosive atmospheres(e.g.,refinery crude distillation units)where the 3500-70M module often monitors pump vibration.Generic cables lack this certification,forcing plants to use costly explosion-proof enclosures—whereas the 149369-01K eliminates this need,cutting installation costs by 30%.

Application Cases and Industry Value:

Case 1:Petrochemical Refinery in Louisiana,USA

A refinery used 149369-01K cables to connect 330103 probes(monitoring hydrocracker reactor pumps)to 3500-70M 176449-09 modules.The refinery’s hazardous Zone 2 environment required ATEX-certified components,and the 149369-01K’s certification eliminated the need for expensive explosion-proof cable glands.The cable’s EMI shielding also withstood interference from nearby variable-frequency drives(VFDs),ensuring the 3500-70M module received accurate vibration data.When one pump’s bearing began to wear,the 3500-70M detected a 0.2mm/s vibration increase via the 149369-01K-transmitted signal,enabling proactive maintenance that avoided a$400,000 pump failure and 3-day production outage.

Case 2:Gas Turbine Plant in Qatar

A gas turbine plant struggled with signal noise in its 3500-70M-based monitoring system,caused by unshielded cables picking up EMI from turbine ignition systems.Replacing these cables with 149369-01K units reduced noise to undetectable levels,allowing the 3500-70M to accurately track shaft runout(0.001mm resolution).The 5m cable length also simplified routing between probes(mounted on turbine casings)and 3500-70M modules(housed in nearby control cabinets).Over 1 year,the plant reduced false alarms by 100%,improved turbine efficiency by 2%(via precise shaft alignment monitoring),and saved$250,000 in unnecessary maintenance.

Related Product Combination Solutions:

Bently Nevada 3500-70M 176449-09:The 149369-01K connects proximity probes to this vibration module,ensuring low-loss data transfer that complements the 3500-70M’s precision monitoring.

Bently Nevada 330103 Proximity Probe:Paired with the 149369-01K to measure shaft position/vibration,the cable preserves the probe’s 0.001mm accuracy for the 3500-70M module.

Bently Nevada 3500/20 Rack:The 149369-01K routes sensor signals to 3500-70M modules mounted in this rack,supporting organized sensor-to-module wiring.

ABB ADPI-01 Analog Input Module:While the 149369-01K serves the 3500-70M,it indirectly supports the ADPI-01 by ensuring the 3500-70M sends accurate data to the ABB DCS.

Bently Nevada 7-Pin Micro Connector(149370-01):Terminates the 149369-01K for secure connection to 330103 probes,maintaining signal integrity.

ABB Enclosure System(IP65):The 149369-01K runs from sensors to 3500-70M modules inside this enclosure,protected from dust/water in outdoor turbine yards.

Bently Nevada AssetVision Software:Accurate data from the 149369-01K-3500-70M chain ensures the software generates reliable vibration trends for predictive maintenance.

ABB Surge Protector(OVR T2):Installed near 3500-70M modules,it protects the 149369-01K and connected probes from voltage spikes,avoiding signal disruption.

Installation,Maintenance,and Full-Cycle Support:

Installing the 149369-01K involves routing the cable from the proximity probe(e.g.,330103 mounted on a turbine)to the 3500-70M 176449-09 module,avoiding tight bends(minimum bend radius:50mm)that could damage shielding.Terminate the cable with compatible 7-pin micro connectors(for probes)and secure the module end to the 3500-70M’s terminal blocks,ensuring proper grounding of the shield(connect to the 3500 rack’s ground bar)to maximize EMI protection.Test signal integrity using Bently Nevada’s System 1 software—verify that vibration data from the 3500-70M matches probe output,a process that takes 30–45 minutes per cable.

Routine maintenance includes quarterly visual inspections:check for cable damage(cuts,abrasions)and ensure connectors are tight(loose connections cause signal dropouts).In harsh environments(e.g.,refineries),clean the cable with a dry cloth to remove chemical residues that could degrade insulation.The 149369-01K’s PTFE insulation and double shielding have a 10+year lifespan,but replace cables if shielding is damaged(exposed conductors increase EMI susceptibility).

We offer a 2-year warranty on the 149369-01K cable,covering shielding failure,insulation degradation,and signal loss beyond specifications.Our technical team provides remote support for routing and termination guidance,with response times under 2 hours.For large-scale 3500 system deployments(e.g.,power plants with 50+sensors),we offer on-site training to help teams install cables for minimal EMI interference.We also stock the 149369-01K globally for fast delivery—critical for minimizing downtime when replacing damaged cables in mission-critical monitoring systems.

Whether you’re connecting probes to 3500-70M modules in a power plant turbine hall or a refinery’s hazardous area,the Bently Nevada 149369-01K delivers the signal integrity,durability,and compatibility needed to keep rotating equipment monitoring reliable.Contact us for a customized cable solution tailored to your 3500 system layout and industrial environment.