Description

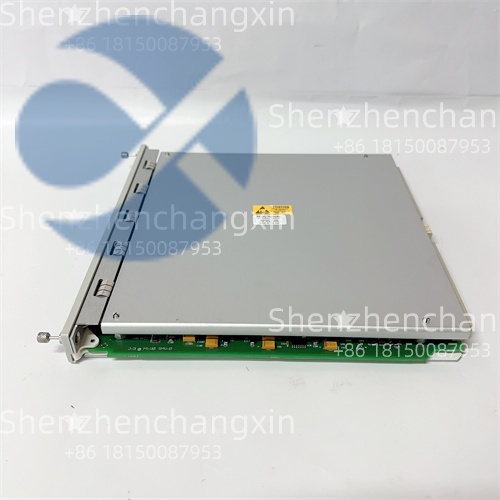

TheBENTLY 350022M 138607-02is a high-performance vibration monitoring module from Bently Nevada’s 3500 series,designed for critical machinery protection.This robust monitor provides continuous vibration measurement and protection for rotating equipment in demanding industrial environments.With advanced signal processing and reliable operation,it ensures early fault detection and prevents catastrophic machinery failures.

Measurement Range:0-20mm/s

Frequency Response:10Hz-2kHz

Output Signals:4-20mA,Relay

Operating Temp:-40°C to 85°C

Protection:IP20

BENTLY 350022M 138607-02 Technical Specifications

Product Model:350022M/138607-02

Manufacturer:Bently Nevada(GE)

Product Type:Vibration Monitor Module

Input Signals:From proximity probes or accelerometers

Measurement Range:Velocity:0-20mm/s,Displacement:0-2000µm

Frequency Response:10Hz to 2kHz(±3dB)

Accuracy:±1%of full scale

Output Signals:4-20mA,Alarm Relays(2 channels)

Power Supply:24VDC±10%

Power Consumption:5W maximum

Operating Temperature:-40°C to+85°C

Storage Temperature:-50°C to+100°C

Relay Contacts:Form C,5A 30VDC

Response Time:Adjustable 1-10 seconds

Enclosure Rating:IP20

Mounting:3500 Series Rack

Dimensions:40mm×130mm×200mm

Weight:1.2kg

Certifications:ATEX,IECEx,cULus

BENTLY 350022M 138607-02 Product Overview

TheBENTLY 350022M 138607-02represents Bently Nevada’s commitment to machinery protection excellence,delivering reliable vibration monitoring for critical industrial equipment.As part of the renowned 3500 series,this monitor module provides comprehensive vibration measurement and protection functions,ensuring continuous equipment health assessment and early fault detection in rotating machinery.

In a power generation turbine application,theBENTLY 350022Mmodules demonstrated exceptional reliability by detecting early bearing degradation nine months before scheduled maintenance.The system’s precise vibration data enabled planned maintenance during a scheduled outage,preventing an estimated$2M in potential damage and production losses.This proactive monitoring capability is particularly valuable in continuous process industries where unplanned downtime carries significant financial impacts.

Compared to basic vibration monitors,the138607-02offers superior signal processing and diagnostic capabilities.Its advanced algorithms can distinguish between various fault types(imbalance,misalignment,bearing defects)and provide early warning of developing problems,allowing maintenance teams to address issues before they escalate into failures.

Technical Principles and Innovative Values

Innovation Point 1:Advanced Signal Processing-TheBENTLY 350022Mutilizes sophisticated digital signal processing algorithms that provide accurate RMS velocity and peak-to-peak displacement measurements.This dual-measurement capability offers comprehensive machinery health assessment,detecting both high-frequency bearing faults and low-frequency imbalance conditions.

Innovation Point 2:Smart Alarm Management-Featuring dual alarm channels with adjustable delay timers,the monitor prevents false alarms during transient conditions while ensuring genuine faults are promptly detected.The programmable alarm setpoints allow customization for specific machinery protection requirements.

Innovation Point 3:Seamless System Integration-As part of the 3500 series,the138607-02module integrates seamlessly with other monitoring modules,providing a comprehensive machinery protection solution.The system’s modular design allows easy expansion and configuration changes without requiring complete system replacement.

Application Cases and Industry Value

A refinery implemented theBENTLY 350022M 138607-02across their critical compressor trains,achieving a 60%reduction in unplanned shutdowns through early detection of rotor dynamics issues.The monitors’reliable performance over five years of continuous operation provided the data needed to extend maintenance intervals by 40%while maintaining safety margins.

In a chemical processing facility,the138607-02modules monitored high-speed centrifugal compressors,detecting impeller fouling three months before performance degradation became critical.This early warning allowed for planned cleaning during a routine turnaround,avoiding$1.5M in lost production and maintenance costs.

Related Product Combination Solutions

3500/42M:Proximitor Power Supply

3500/45M:Dual Channel Vibration Monitor

3300 Series:Complementary monitoring system

3500/RM:Rack Interface Module

3500/22M:Enhanced vibration monitor

Proximity Probes:Complementary displacement monitoring

Accelerometers:Vibration sensing elements

System 1:Diagnostic software platform

Installation,Maintenance,and Full-Cycle Support

Installation Preparation:Verify proper rack slot compatibility and ensure adequate clearance for module insertion.Check power supply specifications and prepare necessary configuration tools.Follow ESD precautions during handling and installation.

Maintenance Protocol:Perform annual calibration verification using reference vibration sources.Monitor module status indicators and maintain event logs.Conduct bi-annual comprehensive system checks to ensure optimal performance.

Technical Support Commitment:We provide comprehensive support including configuration assistance,troubleshooting,and system integration guidance.Our Bently Nevada-certified technicians offer 24/7 support for critical machinery protection applications.

Contact us for professional assistance with yourBENTLY 350022M 138607-02vibration monitoring requirements.Our technical team can provide customized solutions for your specific machinery protection needs.

We at Shenzhen Changxin guarantee genuineBENTLY 350022M 138607-02modules with full quality assurance.Each unit comes with 18-month warranty and professional technical support.Our machinery protection specialists provide expert guidance throughout the product lifecycle.

We maintain adequate inventory to ensure prompt delivery and reliable after-sales service.Partner with us for all your condition monitoring needs and benefit from our extensive application experience in rotating equipment protection and predictive maintenance strategies.