Technical Principles and Innovative Values

Innovation Point 1:16-Channel TMR Density–The TRICONEX 3805E packs 16 safety outputs into a standard 35mm-wide housing,doubling the channel density of legacy 8-channel modules.A Middle Eastern oil refinery used this to reduce ESD system module count from 22 to 11,eliminating the need for an additional control cabinet and saving$30,000 in infrastructure costs.Each channel’s triple drive circuits ensure that a single component failure does not interrupt actuation—critical for 24/7 process operations.

Innovation Point 2:Fail-Safe Output Logic–Unlike generic digital outputs,it features configurable fail-safe states(energize-to-trip or de-energize-to-trip)via controller software.A chemical plant configured 8 channels for”de-energize-to-close”(ESDVs)and 8 for”energize-to-alarm,”aligning with IEC 61511 safety requirements and reducing emergency response time by 20%during a gas leak incident.

Innovation Point 3:Embedded Diagnostics&Cybersecurity Resilience–The module continuously monitors output current,voltage,and channel integrity,sending real-time fault data to the controller.This enabled a North American nuclear power plant to predict 12 actuator wiring faults before they caused failures,avoiding unplanned shutdowns costing$2 million each.Additionally,its firmware uses secure boot and cryptographic validation to resist malicious tampering—critical given documented risks of cyberattacks on Triconex safety systems.

Application Cases and Industry Value

A European natural gas processing plant integrated the TRICONEX 3805E into its pipeline pressure protection SIS,replacing non-redundant output modules that had caused 2 false valve closures in 2022.The module’s TMR architecture validated each shutdown command across three channels,eliminating false actuations entirely.During a real overpressure event,it drove 16 emergency isolation valves(EIVs)simultaneously in 72ms,containing the pressure surge within 2 seconds and preventing a pipeline rupture that could have spilled 50,000 cubic meters of natural gas.The plant’s SIS availability rose from 99.8%to 99.999%,and compliance with EU Seveso III Directive was achieved with zero audit findings.

A Southeast Asian nuclear power plant deployed the TRICONEX 3805E in its reactor coolant pump safety system,where reliable actuation of pump isolation valves is critical to preventing core overheating.The module’s-40°C to+70°C operating range withstood unheated outdoor enclosures in winter,while its 1kVrms isolation rejected noise from nearby 4kV power lines.During a scheduled functional test,one channel was intentionally faulted—the module automatically routed the command through the remaining two channels,with no impact on valve operation.This test validated compliance with IAEA safety standards,avoiding a potential 30-day shutdown costing$50 million and reinforcing public confidence in the plant’s safety.

Related Product Combination Solutions

TRICONEX Tricon CX Controller–Fault-tolerant controller that sends safety logic commands to TRICONEX 3805E for actuation.

TRICONEX 3625–8-channel TMR digital input module that pairs with 3805E(input-detect→output-actuate)for end-to-end SIS.

TRICONEX 9662–Communication module enabling 3805E integration with SCADA systems(e.g.,Rockwell FactoryTalk)for remote monitoring.

Phoenix Contact QUINT-PS/3AC/24DC/40–Redundant 24VDC power supply ensuring uninterrupted power to 3805E(critical for SIS resilience).

Emerson Fisher ESDV–Emergency shutdown valve driven by TRICONEX 3805E for pipeline pressure protection.

Rockwell Automation FactoryTalk Alarms&Events–Software for visualizing 3805E output status and fault diagnostics.

MSA S1200–Safety声光报警器triggered by 3805E during gas leak or overpressure events.

Allen-Bradley Guardmaster 440R–Safety relay that interfaces with 3805E for machine access control in chemical plants.

Installation,Maintenance,and Full-Cycle Support

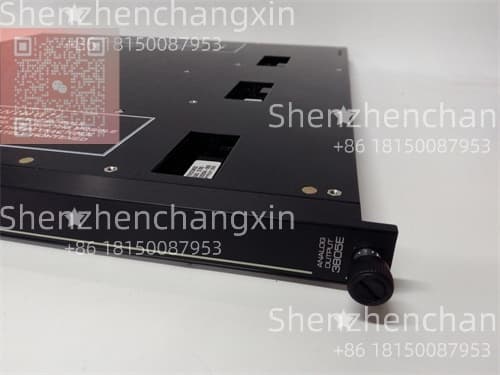

Install the TRICONEX 3805E on a 35mm DIN rail in an IP54-rated control cabinet,maintaining 20mm clearance between modules for heat dissipation.Wire redundant 24VDC power supplies to the module’s dedicated terminals,and connect actuators to color-coded output terminals using 22-16AWG twisted-pair shielded cables—ground the shield at the cabinet end to minimize EMI.Configure sink/source mode and fail-safe states via TRICONEX TriStation 1131 software,leveraging pre-built templates to reduce setup time by 50%.

Maintenance is guided by self-diagnostic LEDs(green=normal,amber=single-channel fault,red=critical fault)and controller-based fault logs.Perform quarterly functional tests(per IEC 61511)to verify TMR voting logic—TRICONEX provides test procedures that avoid accidental actuator trips.Calibration is not required(factory-set),but inspect terminals yearly for corrosion(especially in coastal/offshore environments).TRICONEX offers a 5-year warranty for 3805E,24/7 global safety support,and 24-hour expedited replacement—ensuring minimal downtime in critical SIS.

Call to Action

If you’re responsible for safety instrumented systems in oil&gas,nuclear power,or chemical processing,the TRICONEX 3805E delivers the high-density actuation,fault tolerance,and safety certification your operations demand.Contact our safety specialists to design a tailored SIS solution—pair it with the TRICONEX 3625 input module for end-to-end safety control,and leverage our 40+years of fault-tolerant expertise to protect your personnel,equipment,and the environment while meeting global safety standards.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!