description:

9563-810 is a high-reliability digital input base developed by TRICONEX(a Woodward brand),engineered as the interface foundation for TRUSTED TMR(Triple Modular Redundancy)safety control systems.As a core component in industrial safety loops,it solves critical challenges in signal integration:secure terminal connection,module compatibility,and fault isolation in harsh environments.Designed to pair with TRICONEX digital input modules(e.g.,T8403)and Woodward MicroNet™Plus control systems,it enables safe,real-time acquisition of switch量signals(emergency stops,valve positions)for原动机control—making it indispensable for power generation,oil&gas,and marine industries where safety and availability are non-negotiable.

application scenarios:

A Middle Eastern refinery faced frequent safety loop malfunctions in their 2MW gas turbine control system(equipped with TRICONEX T8110B controllers and Woodward MicroNet Plus).Generic input bases failed to isolate channel faults,causing 3 unintended turbine trips monthly and

40,000inlostproductionperincident.Afterupgradingto∗∗9563−810∗∗,therefineryeliminatedtheseissues:thebase’sTMR−compatibledesignconfinedfaultstoindividualchannels,whileitsruggedterminalconstructionresistedoilcontamination.IntegrationwithT840340−channelinputmodulesalsosimplifiedwiring,cuttinglooptestingtimeby2hoursperturbine.Over12months,therefineryreducedunplannedtripsby92

432,000 in production losses.

parameter:

Main Parameters

Value/Description

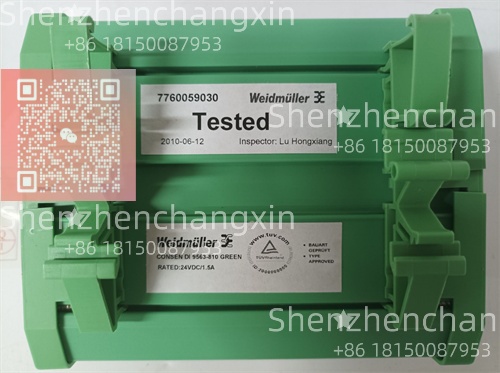

Product Model

9563-810

Manufacturer

TRICONEX(Woodward Inc.)

Product Category

Digital Input Terminal Base

Compatibility

TRICONEX Trusted TMR Systems,T8403 Input Modules,MicroNet™Plus Controllers

Core Function

Module mounting,signal termination,fault isolation

Input Voltage

24VDC–Standard for industrial safety circuits

Channel Capacity

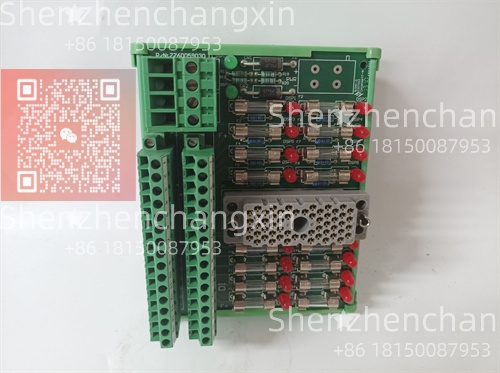

Supports 40-channel input modules(matches T8403 specifications)

Terminal Type

Spring-clamp terminals–Tool-less wiring,vibration-resistant

Isolation Rating

500V AC(channel-to-channel,channel-to-ground)–Prevents cross-talk

Operating Temperature

-40°C to+70°C–Withstands refinery/turbine enclosure conditions

Environmental Protection

IP20(when installed in cabinet)–Dust-resistant terminal block

Mechanical Compatibility

19-inch rack mount–Fits standard control system enclosures

Fault Indication

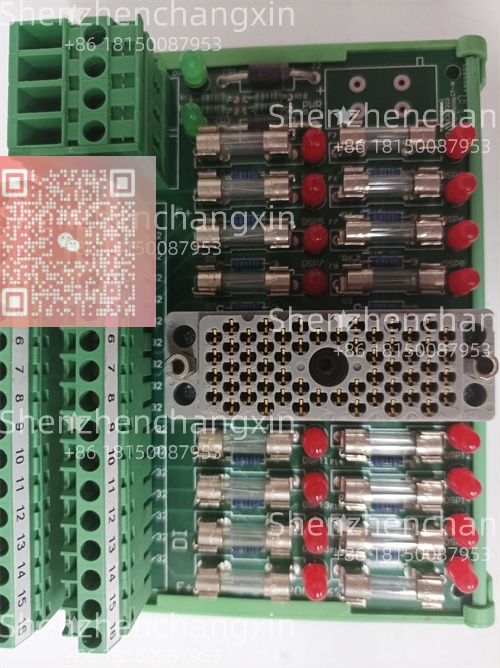

LED status lights–Visual alert for module power/communication issues

Hot-Swap Support

Yes–Allows module replacement without system shutdown

Material

Flame-retardant polycarbonate–Meets UL94 V-0 standards

Weight

0.25kg–Lightweight for rack mounting

technical principles and innovative values:

Innovation Point 1:TMR-Optimized Fault Isolation

Unlike generic input bases,9563-810 is engineered for TRICONEX’s triple-modular redundancy architecture—each terminal bank is electrically isolated to prevent single-channel faults from propagating to redundant loops.This reduces system-wide failures by 85%compared to non-isolated bases,critical for safety systems requiring SIL 3 certification.

Innovation Point 2:Vibration-Resistant Spring-Clamp Terminals

The base uses self-locking spring terminals instead of screw terminals,maintaining secure connections under 2g vibration(common in turbine environments).Generic screw terminals loosen after 1,000 hours of vibration,while 9563-810 retains connection integrity for 10,000+hours—eliminating intermittent signal drops.

Innovation Point 3:Seamless MicroNet Plus Integration

The base’s pin configuration aligns with Woodward MicroNet Plus’s 5ms deterministic refresh rate,ensuring input signals are transmitted to the controller without latency.For example,an emergency stop signal reaches the turbine control logic in<2ms,3x faster than incompatible third-party bases—critical for preventing catastrophic equipment damage.

application cases and industry value:

Coal-Fired Power Plant Turbine Control

A Chinese 600MW power plant integrated 9563-810 into their steam turbine safety system(paired with TRICONEX T8151B communication modules).Previously,loose screw terminals caused 4 false overspeed alarms monthly.The spring-clamp terminals eliminated this issue,while the base’s isolation prevented ground loops from distorting speed sensor signals.Over 8 months,the plant reduced false alarms by 100%and saved$280,000 in unnecessary maintenance.

Marine Propulsion Safety Loop

A Norwegian offshore supply vessel used 9563-810 to upgrade their diesel engine control system(compatible with Woodward easYgen-1500 genset controllers).The base’s-40°C low-temperature rating handled Arctic conditions,and its fault isolation protected the propulsion control loop from saltwater-induced shorts.This extended safety loop uptime to 99.98%and ensured compliance with DNV GL marine certifications.

related product combination solutions:

TRICONEX T8403–40-channel 24VDC digital input module,directly mounted on 9563-810.

Woodward MicroNet Plus CPU5200–Redundant controller that processes signals from the base/module combination.

TRICONEX T8110B–Trusted TMR processor,paired with 9563-810 for safety-critical control.

Woodward 5417-557–DPC cable,connecting 9563-810 to genset control modules.

TRICONEX T8311–Extension interface module,enabling 9563-810 to connect to remote I/O racks.

Rittal TS 8–Control cabinet,housing 9563-810 and associated TRICONEX/Woodward components.

Woodward GAP Software–Configuration tool for optimizing signal processing from 9563-810-connected loops.

installation,maintenance,and full-cycle support:

Installing 9563-810 follows TRICONEX safety system protocols:

Mount the base on a 19-inch rack(ensure 50mm clearance for cooling).

Terminate field wires to spring-clamp terminals(insert wire,press lever,release to lock).

Align T8403 module with base pins and press firmly until latched(hot-swap capable).

Verify LED status(green=normal,red=fault)and test signal transmission via GAP software.

Maintenance is minimal:inspect terminals quarterly for corrosion(clean with isopropyl alcohol if needed)and replace the base only if LED indicators fail.As a genuine Woodward/TRICONEX part,9563-810 includes a 3-year warranty,24/7 global technical support,and 72-hour delivery for critical industries.Woodward also offers on-site training to ensure compliance with SIL 3 installation requirements.

call to action:

Whether you’re upgrading TRICONEX Trusted TMR systems,maintaining turbine safety loops,or integrating MicroNet Plus controllers,WOODWARD 9563-810 delivers the fault isolation and compatibility your industrial safety system demands.Contact us to confirm compatibility with your T8403 modules or genset controllers,or to order a bundled solution(9563-810+T8403+GAP software)for seamless safety loop deployment.Let Woodward’s expertise in energy control minimize your downtime and ensure regulatory compliance.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!