Description

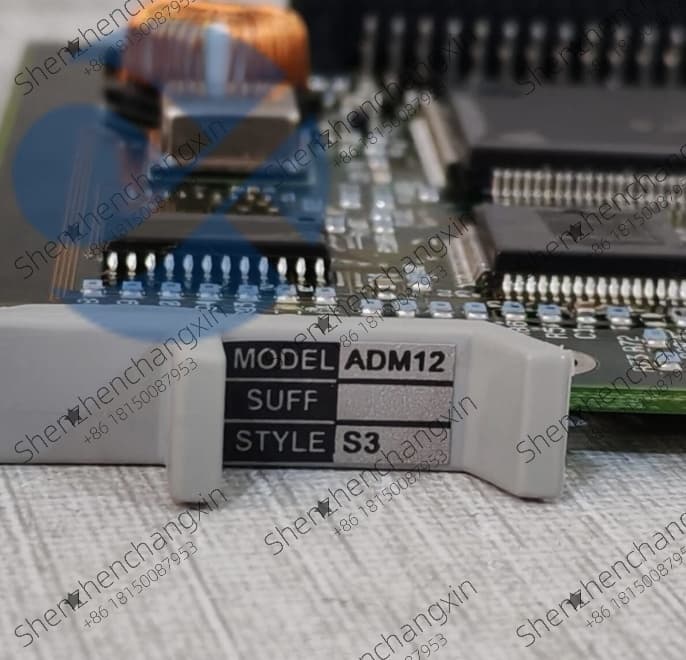

The YOKOGAWA ADM12 S3 is an 8-slot base unit(backplane)designed exclusively for the ProSafe-RS safety instrumented system(SIS),serving as the central mechanical and electrical backbone for SIL 3-certified control configurations.It enables modular integration of redundant CPUs,power supplies,communication modules,and safety I/O cards in high-integrity applications where process safety is paramount.Engineered for reliability and fault tolerance,the ADM12 S3 supports hot-swapping of modules,real-time diagnostics,and seamless redundancy—ensuring continuous operation and rapid recovery in mission-critical environments.

Application Scenarios

At a liquefied natural gas(LNG)terminal in Qatar,engineers faced the challenge of upgrading their emergency shutdown(ESD)system to meet stringent SIL 3 requirements while minimizing downtime during commissioning.The existing single-point failure risks in the control architecture posed unacceptable hazards.The solution was the deployment of dual YOKOGAWA ADM12 S3 base units configured in a fully redundant ProSafe-RS safety PLC rack.One ADM12 S3 housed the primary CPU and I/O,while the second provided complete redundancy with automatic failover.During a simulated turbine trip test,the system responded in under 50ms,with the standby CPU taking over seamlessly when the active CPU was manually removed—demonstrating true hot-swap capability.Operators highlighted the intuitive LED indicators that instantly identified module status,reducing troubleshooting time by over 60%.This implementation ensured zero unplanned outages post-commissioning,proving the YOKOGAWA ADM12 S3 as the foundation of a resilient,future-ready safety infrastructure.

Parameters

Main Parameters Value/Description

Product Model ADM12 S3(also marked as ADM12-S3)

Manufacturer Yokogawa Electric Corporation

Product Category Safety System Base Unit/I/O Backplane

Number of Slots 8(supports CPU,PS,COM,and I/O modules)

Compatible System ProSafe-RS Safety PLC(R-Series)

Redundancy Support Full CPU and power supply redundancy(dual configuration)

Hot-Swap Capability Yes–modules can be replaced online without system shutdown

Bus Type Dedicated safety backplane bus with error-checking protocol

LED Indicators Per-slot RUN,RDY,ERR LEDs+system-level status lights

Installation Method 35mm DIN rail mounting(standard industrial profile)

Power Supply Input 24 V DC(via dual PS modules for redundancy)

Isolation Reinforced isolation between modules and backplane

Operating Temperature 0°C to+55°C(no derating)

Certifications IEC 61508 SIL 3,IEC 62061,ISO 13849-1

Note:Used with Yokogawa FIO,FBM,FCU series safety I/O and CPU modules.

Technical Principles and Innovative Values

Innovation Point 1:Purpose-Built for SIL 3 Safety Integrity

The YOKOGAWA ADM12 S3 is not a general-purpose backplane—it is engineered specifically for ProSafe-RS,ensuring deterministic data transfer,hardware-level error detection,and compliance with functional safety standards up to SIL 3.Its dedicated bus architecture prevents unauthorized access and guarantees fail-safe behavior.

Innovation Point 2:True Modular Redundancy with Automatic Failover

By supporting dual CPUs and dual power supplies within a single 8-slot frame,the ADM12 S3 enables full hardware redundancy.In the event of a CPU or power failure,the standby unit takes over within milliseconds,maintaining uninterrupted safety monitoring—critical in petrochemical and offshore platforms.

Innovation Point 3:Hot-Swap Design for Maximum Uptime

Unlike conventional base units requiring system shutdown for maintenance,the YOKOGAWA ADM12 S3 allows live replacement of faulty I/O,CPU,or power modules.Combined with real-time diagnostics,this feature minimizes mean time to repair(MTTR)and enhances overall system availability.

Innovation Point 4:Integrated Diagnostics with Visual Status Feedback

Each slot features independent RUN,RDY,and ERR LEDs,providing immediate visual insight into module health.This simplifies field diagnostics and reduces reliance on software tools during commissioning or emergency response.

Application Cases and Industry Value

In a major ethylene cracker plant in South Korea,a legacy safety system suffered from frequent spurious trips due to aging backplanes and poor signal integrity.Engineers replaced the obsolete chassis with new YOKOGAWA ADM12 S3 units integrated into a ProSafe-RS rack.Over the next 18 months,the number of false alarms dropped to zero,and system availability reached 99.998%.Maintenance teams praised the ease of replacing a failed FIO digital input module during normal operations—without halting production.The investment paid off within two years through reduced downtime and improved process safety performance.

At a nuclear power auxiliary safety system in Finland,the ADM12 S3 was used to house safety logic solvers for reactor coolant monitoring.Its robust isolation and electromagnetic compatibility(EMC)performance ensured reliable operation despite high radiation and EMI levels.Regulatory auditors commended the system’s transparency and diagnostic capabilities,facilitated by the ADM12 S3’s clear status indication and logging support.

Related Product Combination Solutions

YOKOGAWA FSC10-R:Redundant safety CPU for ProSafe-RS;installs directly into the ADM12 S3 for executing safety logic with ultra-fast scan times.

YOKOGAWA PS401-R:Dual-channel 24V DC power supply module;provides redundant power to the ADM12 S3 backplane for uninterrupted operation.

YOKOGAWA FIO-AD31:16-channel analog input module;connects to temperature and pressure sensors via the ADM12 S3 for critical process monitoring.

YOKOGAWA FIO-ID11:32-channel digital input module;interfaces with emergency pushbuttons and limit switches in ESD systems.

YOKOGAWA FIO-OD11:Digital output module;drives solenoid valves and alarms based on logic from the FSC10-R CPU.

YOKOGAWA Vnet/IP Interface Module:Enables secure data exchange between the ADM12 S3-based SIS and CENTUM VP DCS for operator visibility.

YOKOGAWA ProSafe-RS Engineering Station:Software platform used to configure,test,and validate safety logic deployed on the ADM12 S3 system.

YOKOGAWA ADM11 S3:5-slot base unit;ideal for smaller safety loops where space is limited but same reliability is required.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!