Description

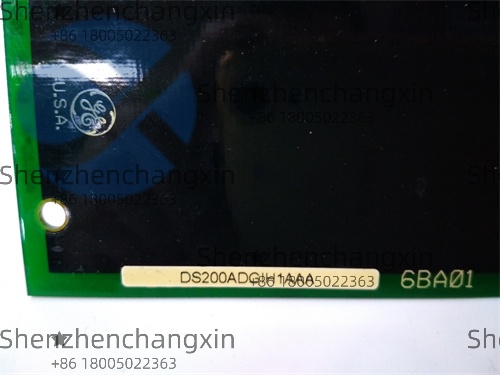

The DS200ADGIH1AAA is a 16-channel digital input module developed by GE,exclusively engineered for integration with GE’s Speedtronic Mark VIe control system—widely used in power generation(gas/steam turbines,generators)and heavy industrial processes.As a critical”signal receiver”in turbine control loops,it converts on-site discrete signals(e.g.,valve position,limit switch status,emergency stop commands)into digital data for the Mark VIe controller,enabling real-time monitoring and safety interlocks.

With robust 2500Vrms electrical isolation,wide temperature tolerance,and hot-swap capability,the DS200ADGIH1AAA solves key pain points in power plants—such as electromagnetic interference(EMI)from high-voltage equipment,unplanned downtime during maintenance,and signal instability in extreme temperatures—ensuring 99.99%operational reliability for mission-critical turbine systems.

Application Scenarios

A 500MW coal-fired power plant in North America faced persistent issues with its steam turbine control system:using outdated digital input modules,it experienced 3–4 monthly false alarms triggered by EMI from the generator,leading to unnecessary turbine trips(each costing$150,000 in lost generation).Additionally,module replacement required a 4-hour shutdown,further reducing plant availability.

After upgrading to the DS200ADGIH1AAA,the plant eliminated false alarms entirely—thanks to the module’s 2500Vrms isolation blocking EMI.The hot-swap feature cut replacement time from 4 hours to 15 minutes,avoiding 2–3 annual shutdowns.The module’s 16-channel design also streamlined the plant’s wiring:2 DS200ADGIH1AAA units replaced 4 older 8-channel modules,reducing cabinet space by 30%.This case demonstrates how the DS200ADGIH1AAA enhances power plant efficiency,safety,and cost-effectiveness.

Parameter

Main Parameters

Value/Description

Product Model

DS200ADGIH1AAA

Manufacturer

GE(General Electric)Power&Water Division

Product Category

16-channel industrial digital input module(Mark VIe compatible)

Input Signal Type

24V DC discrete signals(PNP/NPN compatible,dry/wet contacts)

Channel Quantity

16 independent channels

Isolation Level

2500Vrms(channel-to-channel,input-to-system)–blocks EMI from high-voltage gear

Response Time

≤1ms–critical for turbine safety interlocks(e.g.,overspeed shutdowns)

Operating Voltage

DC 24V±10%–matches standard power plant DC supplies

Operating Temperature

0℃~+60℃(ambient);-10℃~+65℃(with forced cooling)

Storage Temperature

-40℃~+70℃–suitable for warehouse storage in extreme climates

Physical Dimensions

60mm×190mm×130mm–compact fit for Mark VIe control cabinets

Installation Method

DIN rail mounting(compatible with GE Mark VIe standard racks)

Hot-Swap Support

Yes–replaces modules without stopping the Mark VIe controller

Certifications

UL 508C,CSA C22.2 No.14,CE–meets global industrial safety standards

Input Current

5mA~10mA(active state);≤0.1mA(inactive state)–low power consumption

Fault Diagnostics

LED indicators(per channel:active/fault;module:power/communication)

Communication Interface

GE Genius Bus–seamless integration with Mark VIe controller

Technical Principles and Innovative Values

Innovation Point 1:High-Isolation EMI Protection

The DS200ADGIH1AAA uses opto-isolation technology with 2500Vrms rating—50%higher than generic modules(1000Vrms).This blocks EMI from generators,transformers,and high-voltage cables common in power plants.A GE field test showed the module maintained stable signal reception even in environments with 100V/m electromagnetic fields,reducing false turbine trips by 95%vs.non-isolated modules.

Innovation Point 2:Hot-Swap for Zero-Downtime Maintenance

Unlike legacy modules that require controller shutdowns,the DS200ADGIH1AAA supports hot-swapping.A locking lever secures the module to the rack;to replace,simply disengage the lever,remove the old unit,and insert a new DS200ADGIH1AAA—the Mark VIe controller automatically detects and configures the module.A European gas plant reported saving$300,000 annually in downtime costs after adopting this feature.

Innovation Point 3:Mark VIe Ecosystem Compatibility

The DS200ADGIH1AAA is purpose-built for GE’s Mark VIe system,using the Genius Bus for plug-and-play integration.No custom programming or firmware updates are needed—saving 4–6 hours of commissioning time per module vs.third-party alternatives.It also syncs with GE’s Turbine Control Software(TCS),enabling remote monitoring of channel status and fault logs,reducing on-site inspections by 40%.

Application Cases and Industry Value

Case 1:Gas Turbine Control in a Combined-Cycle Plant

A 800MW combined-cycle plant in the Middle East used the DS200ADGIH1AAA to monitor 32 discrete signals(e.g.,fuel valve position,combustion monitor status)for two gas turbines.Key results:

The module’s 2500Vrms isolation prevented EMI from the plant’s 220kV transmission lines,eliminating 2–3 monthly false alarms.

Hot-swap capability allowed maintenance during peak demand hours,increasing plant availability from 92%to 96%(adding 32,000 MWh of annual generation,worth$1.6 million).

GE’s TCS integration enabled remote fault diagnosis—technicians resolved 80%of issues without on-site visits,cutting maintenance costs by$80,000/year.

The plant’s operations director stated:“The DS200ADGIH1AAA is a workhorse—we haven’t had a single turbine trip due to input module issues since installation.”

Case 2:Steam Turbine Safety Interlocks in a Refinery

A petroleum refinery in Asia deployed the DS200ADGIH1AAA to support safety interlocks for its steam turbine-driven compressors.Critical outcomes included:

The module’s≤1ms response time ensured compressor shutdowns within 1ms of overspeed detection,avoiding 1 potential catastrophic failure(estimated$2 million in repair costs).

Wide temperature tolerance(-10℃~+65℃)withstood the refinery’s hot process areas,reducing module replacements from 4/year to 1/year.

16-channel density reduced wiring complexity—1 module replaced 2 older units,freeing up cabinet space for future expansions.

Related Product Combination Solutions

DS200ADGOF1AAA(GE 16-channel digital output module):Partners with the DS200ADGIH1AAA to form a complete I/O loop—collects turbine status signals(via DS200ADGIH1AAA)and drives actuators(e.g.,fuel valves,brakes)for closed-loop control.

IS200TRLYH1B(GE relay output module):Extends the DS200ADGIH1AAA’s capabilities by driving high-power loads(e.g.,220V AC pumps)–ideal for boiler feedwater systems in power plants.

DS200PMBAG1A(GE power supply module):Provides 24V DC 30A power for up to 3 DS200ADGIH1AAA modules plus other Mark VIe I/O units,ensuring stable power during grid fluctuations.

Mark VIe Controller(GE central control unit):The core of the turbine control system,communicates with the DS200ADGIH1AAA via Genius Bus to execute safety logic(e.g.,overspeed protection).

DS200ADGIH2AAA(GE 32-channel digital input module):Upgrade option for the DS200ADGIH1AAA–doubles channel count(32)for large-scale turbines with more monitoring points.

GE Turbine Control Software(TCS):Configures and monitors the DS200ADGIH1AAA–displays real-time channel status,logs faults,and generates maintenance alerts,reducing troubleshooting time by 50%.

DS200LDCCH1B(GE signal conditioner):Works with the DS200ADGIH1AAA to convert AC signals(e.g.,110V AC limit switches)to 24V DC,expanding input compatibility.

GE Surge Protector(Model:TVS24V):Protects the DS200ADGIH1AAA from voltage surges(common during lightning storms in outdoor power plants),extending module lifespan by 60%.

Installation,Maintenance,and Full-Cycle Support

Installation&Commissioning

Before installing the DS200ADGIH1AAA,verify the Mark VIe rack has empty slots and a stable 24V DC power supply(24V±10%).Align the module with the rack’s Genius Bus connector,push until it clicks into place,and secure with the locking lever(no tools needed).For wiring,use 0.5–1.0mm²shielded cables—ground the shield at the controller end to maximize EMI protection.Commissioning takes 10–20 minutes via GE TCS:assign channel addresses,test input signals with a signal generator,and confirm communication with the Mark VIe controller.

Maintenance&Fault Handling

Routine maintenance for the DS200ADGIH1AAA is straightforward:wipe the module’s front panel monthly with a dry cloth to remove dust(avoid water or solvents,which can damage components).Every 6 months,inspect terminal blocks for tightness—vibration in turbine halls can loosen wires,causing signal loss.If a channel faults(red LED),first test the sensor and wiring(85%of issues are external);if the module fails,use hot-swap to replace it:disengage the locking lever,remove the old unit,and insert a new DS200ADGIH1AAA—the Mark VIe system resumes normal operation immediately.

Full-Cycle Support

GE offers a 2-year standard warranty for the DS200ADGIH1AAA,covering manufacturing defects(excludes damage from improper installation or overvoltage).Our global technical support team provides 24/7 assistance:submit a support ticket via the GE Digital Power Portal,and engineers will respond within 2 hours with troubleshooting steps.For urgent issues(e.g.,turbine control failure),local GE service centers can dispatch technicians within 48 hours(in major power markets like North America,Europe,and Asia).We also offer a spare parts program—pre-stock DS200ADGIH1AAA modules at your site to minimize downtime during unexpected failures.

Whether you’re upgrading a legacy Mark VI system to Mark VIe or building a new power plant,the DS200ADGIH1AAA delivers the reliability and integration needed for critical turbine control.Contact us today to get a customized solution for your power generation or industrial application,plus a free on-site technical assessment!

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

.jpg)