Description

The GE IC670ALG310-JA is an 8-channel analog current input module designed for the GE Fanuc RX3i Programmable Logic Controller(PLC)system.Manufactured by GE Automation&Controls,this high-precision module is engineered for industrial process monitoring and control applications requiring reliable 4-20mA signal acquisition.

It supports standard 4-20mA current inputs from field devices such as temperature transmitters,pressure sensors,flow meters,and level controllers.With 16-bit resolution and±0.1%accuracy,the IC670ALG310-JA ensures dependable data acquisition for critical control loops.It features individual channel configuration,HART communication pass-through,and hot-swap capability,making it ideal for continuous-process environments where uptime is paramount.

Application Scenarios

At a petrochemical refinery in Texas,operators struggled with inconsistent temperature readings across multiple reactor zones.The legacy analog input modules in their RX3i PLC system exhibited signal drift and poor noise immunity,leading to frequent manual recalibrations and process instability.To resolve this,the automation team upgraded to the GE IC670ALG310-JA across all reactor monitoring racks.Each IC670ALG310-JA module was connected to eight thermocouple transmitters,providing stable,high-fidelity data to the control system.The±0.1%accuracy and built-in filtering eliminated signal noise from nearby high-power equipment.When a sudden spike in Reactor#2 temperature was detected,the IC670ALG310-JA delivered clean,real-time data that triggered an automatic cooling sequence—preventing a potential overpressure event.The plant reported a 30%reduction in process deviations and zero unplanned shutdowns in the following year,proving that precision I/O isn’t just a component upgrade—it’s a safety and efficiency game-changer.

Parameter

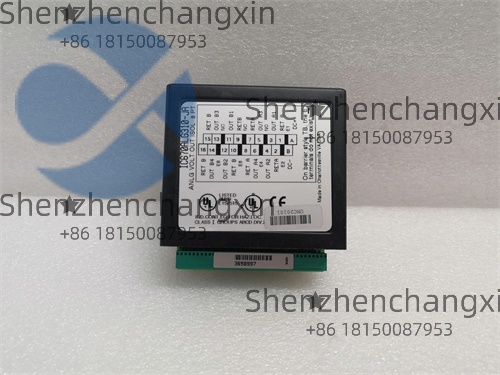

Main Parameters Value/Description

Product Model IC670ALG310-JA

Manufacturer GE Automation&Controls

Product Category Analog Input Module–Current(4-20mA)

Number of Channels 8 independent channels–supports loop-powered or externally powered sensors

Input Signal Type 4-20mA DC–standard for industrial process transmitters

Resolution 16-bit–ensures fine granularity in measurement

Measurement Accuracy±0.1%of span–minimizes drift and enhances control loop stability

Sampling Rate 125µs per channel–fast response for dynamic processes

Isolation Channel-to-channel and channel-to-ground–500V AC–prevents ground loops

HART Support Passive HART pass-through–allows access to transmitter diagnostics

Installation Method DIN rail mount,RX3i chassis plug-in–supports hot-swap without system shutdown

Operating Temperature 0°C to 60°C–suitable for industrial control panels and harsh environments

Communication Interface GE RX3i Backplane–integrates with Proficy Logic Developer and iFix HMI

Technical Principles and Innovative Values

Innovation Point 1:High-Precision 16-Bit Acquisition

The GE IC670ALG310-JA uses a 16-bit A/D converter per channel,delivering exceptional resolution and linearity.This enables the system to detect minute changes in process variables—critical for tight control in chemical reactions,distillation,and batch processing.

Innovation Point 2:True Channel-to-Channel Isolation

Unlike shared-reference modules,the IC670ALG310-JA provides full isolation between channels and from ground.This eliminates cross-talk and ground loop errors,a common issue in plants with mixed AC/DC equipment and long cable runs.

Innovation Point 3:Passive HART Compatibility

While the module does not actively communicate with HART devices,it allows HART signals to pass through to a separate HART master or handheld communicator.This enables technicians to access transmitter diagnostics,calibration data,and health status without removing the module.

Innovation Point 4:Hot-Swap&Auto-Recognition

The GE IC670ALG310-JA supports hot-swapping.When replaced,the RX3i CPU automatically detects the module and loads its configuration from the controller,minimizing downtime during maintenance or module failure.

.jpg)