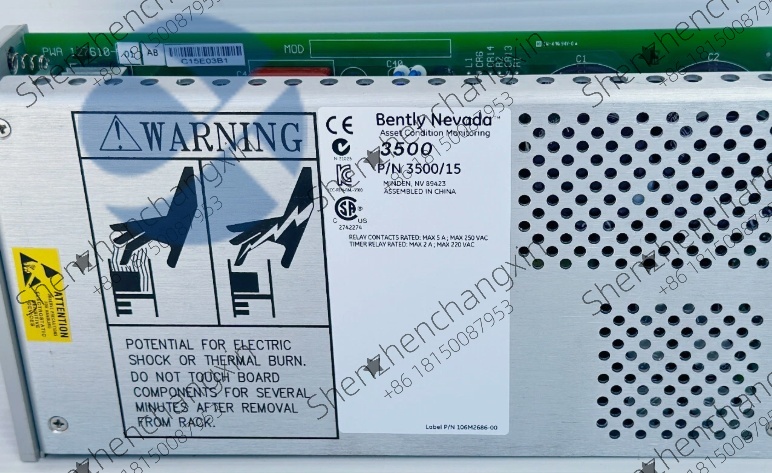

Product Description

TheBently Nevada 3500-15is a5A Relay Moduledesigned for machinery protection systems,providing critical alarm and shutdown functions in the Bently Nevada 3500 monitoring system.This relay module offers two independent Form C relay outputs(2A rating)for connecting to external safety systems.Engineered for high-reliability applications in critical machinery protection,it ensures safe operation of turbines,compressors,and other rotating equipment.

Application Scenarios

In a natural gas compressor station,theBently Nevada 3500-15relay module monitors vibration levels on a critical centrifugal compressor.When vibration exceeds predefined alarm thresholds,the3500-15activates its relay outputs to trigger warning alarms in the control room.If vibrations reach dangerous levels,the second relay initiates an emergency shutdown,preventing catastrophic equipment failure that could result in millions of dollars in damage and weeks of production downtime.

Technical Specifications

Parameter

Specification

Product Model

3500-15

Manufacturer

Bently Nevada(Baker Hughes)

Product Type

5A Relay Module(2A rating)

Relay Configuration

Two independent Form C relays

Contact Rating

2A 30VDC resistive,0.5A 120VAC

Operating Voltage

24VDC from rack backplane

Response Time

<10 milliseconds

Isolation

1500V RMS channel-to-channel

LED Indicators

Relay status(energized/de-energized)

Compatibility

Bently Nevada 3500 series racks

Operating Temperature

-40°C to+85°C

Safety Standards

SIL 2 capable

Agency Approvals

UL,CE,cULus

Technical Principles and Innovative Values

Dual Independent Relays:TheBently Nevada 3500-15provides two completely isolated Form C relays,allowing for separate alarm and shutdown functions with independent circuitry for enhanced reliability

Fast Response Time:With response times under 10 milliseconds,the module ensures rapid reaction to critical machinery conditions,minimizing potential damage during fault conditions

SIL 2 Capability:Designed to meet Safety Integrity Level 2 requirements,making it suitable for safety-critical applications in process industries

Application Cases and Industry Value

A power generation facility using gas turbines implemented theBently Nevada 3500-15relay modules across their turbine protection systems.During an unexpected blade failure incident,the3500-15modules detected abnormal vibrations and initiated a controlled shutdown within milliseconds,preventing secondary damage to the turbine casing and bearings.The rapid response saved an estimated$3.5 million in repair costs and reduced downtime from potential months to just three weeks for scheduled maintenance and repair.

Related Product Combination Solutions

Bently Nevada 3500/42M:Proximitor transducer interface module

Bently Nevada 3500/22M:Velocity transducer interface module

Bently Nevada 3500/25:Keyphasor module for phase reference

Bently Nevada 3500/32:4-20mA output module

Bently Nevada 3500/92:Communication gateway

Bently Nevada 3500/RM:Rack power supply and chassis

Installation,Maintenance,and Full-Cycle Support

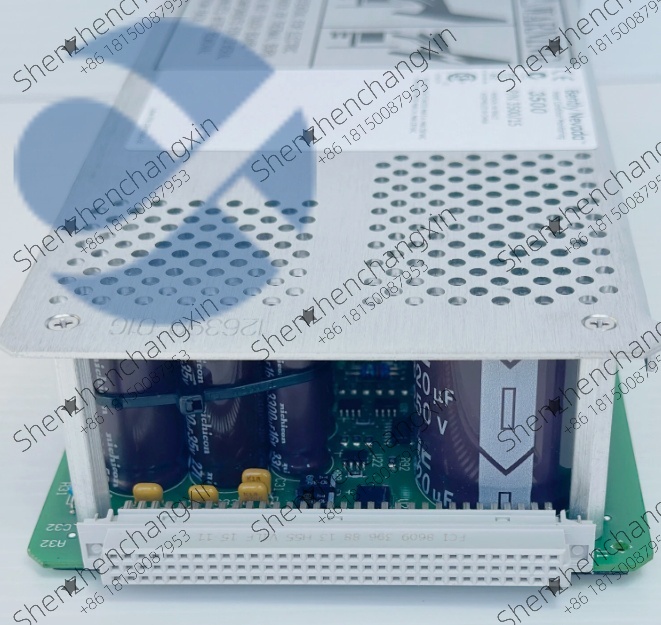

Installation Protocol:When installing theBently Nevada 3500-15,ensure proper rack slot compatibility and follow electrostatic discharge precautions.Verify relay configuration settings via the 3500 configuration software before energizing the system.Use appropriate wire gauges for relay outputs based on current requirements.

Maintenance Strategy:Perform annual functional testing of all relay outputs using the 3500 system’s test capabilities.Verify contact resistance and insulation resistance during scheduled maintenance outages.Maintain calibration records and test results for compliance and audit purposes.

Technical Support Commitment:We provide comprehensive support forBently Nevada 3500-15systems including configuration assistance,troubleshooting,and emergency replacement services.Our inventory includes factory-calibrated modules with full traceability.

Contact our protection system specialists for technical consultation and reliable sourcing of Bently Nevada 3500-15 relay modules.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!