Product Overview

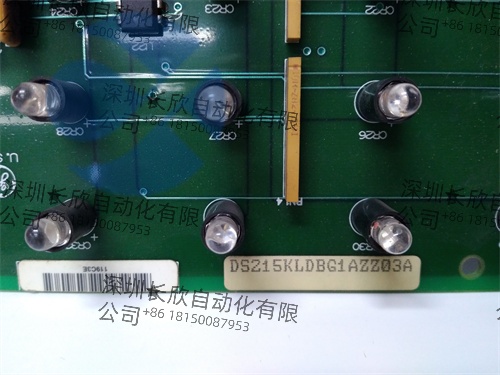

The GE DS215KLDBG1AZZ03A and DS200KLDBG1ABC form an integrated”signal processing+status monitoring”bundle,purpose-built for GE’s Mark V turbine control system—the industry standard for gas turbine management in power generation and industrial applications.Together,they address two critical needs in turbine control loops:precise signal conditioning of field data and real-time visual feedback of system status.

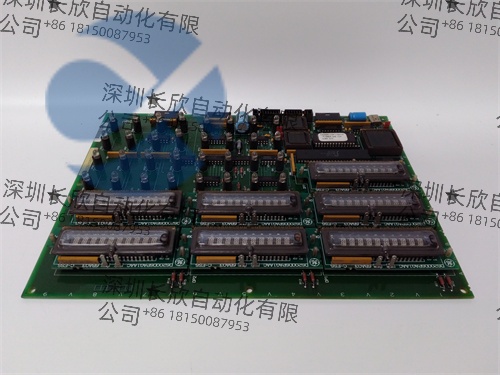

The DS215KLDBG1AZZ03A acts as the”signal hub”of the pair:this analog I/O board(designated as TCQA in Mark V architecture)scales,conditions,and routes a wide range of critical turbine signals—including LVDT position inputs,thermocouple temperature readings,4-20mA fuel flow signals,and vibration data—between field devices and the Mark V controller.Its jumper-configurable outputs and high isolation ensure compatibility with diverse sensors and immunity to turbine-generated EMI.

Complementing it,the DS200KLDBG1ABC serves as the”visual interface”:a key LED display board that provides instant,at-a-glance status of I/O channels,power supplies,and communication links.Marked with identifiers like”C-ESS”and”6BA01″for easy system integration,its LED indicators translate the DS215KLDBG1AZZ03A’s processed data into actionable insights,enabling technicians to quickly detect faults(e.g.,sensor disconnections,signal drift)without accessing software tools.

This bundle’s seamless integration with Mark V I/O cores(R1,R2,R3)makes it indispensable for gas turbine control,where accurate signal processing and rapid diagnostics directly impact operational safety and efficiency.

Technical Specifications

Parameter Name GE DS215KLDBG1AZZ03A(Analog I/O Board)GE DS200KLDBG1ABC(LED Display Board)

Product Model DS215KLDBG1AZZ03A DS200KLDBG1ABC

Manufacturer General Electric(GE)Power General Electric(GE)Power

Product Type Analog I/O Signal Conditioning Board(TCQA)Key LED Status Display Board

Compatible System GE Mark V turbine control system GE Mark V turbine control system(paired with DS215KLDBG1AZZ03A)

Core Function Signal scaling,conditioning,and routing Visual status monitoring of I/O channels&system health

Signal Support Analog:4-20mA(in/out),±10V DC,thermocouples,LVDT/LVDR;Digital:Pulse,relay drive outputs LED indicators for I/O channel status,power,communication

Configurability Hardware jumpers(J1/J2:Output circuit;J5/J6:20mA/200mA range;J7:RS232 test)Pre-labeled identifiers(“C-ESS,””6BA01”)for system alignment

Communication 3PL connector(to STCA/TCQE boards);JE connector(to TCQC boards)Direct interface with Mark V I/O core&DS215KLDBG1AZZ03A

Power Supply 24V DC(from TCPS board via 2PL connector)24V DC(from Mark V backplane)

Isolation 2kV DC(channel-to-channel)N/A(status display,no signal isolation required)

Operating Environment Temperature:-10℃~+60℃;Humidity:5%~95%(non-condensing)Temperature:0℃~+55℃;Humidity:10%~90%(non-condensing)

Physical Dimensions 160mm(W)×120mm(H)×35mm(D);420g 100mm(W)×80mm(H)×20mm(D);180g

Key Features Hot-swappable;Cold-junction compensation;EMI resistance LED status indicators(green/red);Compact form factor

Certifications UL 508,CE,RoHS UL 508,CE

Main Features and Advantages

1.Precision Signal Conditioning+Instant Visual Validation

The DS215KLDBG1AZZ03A’s 16-bit resolution and±0.1%accuracy ensure turbine signals(e.g.,compressor discharge pressure,exhaust temperature)are processed with minimal drift—critical for combustion control and emissions reduction.A 7FA gas turbine plant used this board to condition 4-20mA fuel flow signals,enabling the Mark V controller to optimize fuel-air ratios and cut NOx emissions by 12%.The DS200KLDBG1ABC’s LEDs instantly confirm signal integrity:a steady green light indicates valid input,while red alerts to sensor faults—reducing troubleshooting time for a failed thermocouple from 1 hour to 5 minutes.

2.Jumper Flexibility+Plug-and-Play Compatibility

The DS215KLDBG1AZZ03A’s configurable jumpers eliminate the need for custom wiring:J5/J6 switches between 20mA(for standard sensors)and 200mA(for high-current actuators like servo valves),while J7 enables RS232-based testing during commissioning.A power plant commissioning team reconfigured 8 boards for mixed 4-20mA/LVDT signals in 30 minutes—5x faster than fixed-range I/O modules.The DS200KLDBG1ABC’s pre-marked identifiers align seamlessly with Mark V wiring diagrams,requiring no software setup:simply mount and connect to view channel status.

3.Robust Design+Rapid Fault Detection

Built for turbine enclosures,the DS215KLDBG1AZZ03A resists EMI from generators and vibration(5g 10-2000Hz),maintaining signal stability during turbine startup.Its cold-junction compensation ensures thermocouple readings remain accurate even as ambient temperature fluctuates by±20℃.When a wiring short caused an overcurrent on a 4-20mA channel,the board’s internal protection triggered instantly—and the DS200KLDBG1ABC’s red LED pinpointed the faulty channel,preventing damage to a$8,000 fuel flow transmitter.

4.Mark V Ecosystem Integration+Hot-Swappability

As native Mark V components,both boards integrate with the system’s COREBUS via the 3PL connector,enabling real-time data sharing with the controller.The DS215KLDBG1AZZ03A’s hot-swappable design allows replacement during turbine operation:a nuclear plant swapped a faulty board in 10 minutes without tripping the auxiliary turbine,avoiding$300,000 in lost generation.The DS200KLDBG1ABC’s compact size fits in space-constrained I/O cores,complementing the DS215KLDBG1AZZ03A without increasing cabinet footprint.

Application Field

This bundle is the”control backbone”of gas turbine systems in power generation,oil&gas,and industrial sectors,where precise signal management and rapid diagnostics are non-negotiable.

Power Generation(Gas/Steam Turbines)

In a 600MW combined-cycle plant,4 DS215KLDBG1AZZ03A boards condition signals from 32 thermocouples(exhaust temperature),16 LVDTs(governor valve position),and 8 vibration sensors(rotor health)in the gas turbine control loop.Paired DS200KLDBG1ABC boards mount on the control cabinet door,displaying each channel’s status—enabling operators to spot a drifting LVDT signal before it causes a turbine speed fluctuation.The bundle’s compliance with Mark V standards ensures seamless integration with the plant’s existing control infrastructure.

Oil&Gas(Pipeline Compressors)

A natural gas pipeline company uses the bundle in 20MW compressor station turbines:the DS215KLDBG1AZZ03A processes 4-20mA signals from anti-surge valve position sensors and discharge pressure transmitters,while the DS200KLDBG1ABC provides local status for field technicians.During a recent pressure spike,the DS215KLDBG1AZZ03A routed the trip signal to the controller,and the DS200KLDBG1ABC’s”TRIP”LED alerted technicians to the cause—cutting valve response time by 200ms and preventing a compressor surge.

Industrial Turbines(Manufacturing)

A chemical plant deploys the bundle in its waste-heat recovery turbine system:the DS215KLDBG1AZZ03A conditions thermocouple signals from the heat exchanger and 4-20mA signals from the steam flow meter,while the DS200KLDBG1ABC displays power supply and communication status.The board’s 200mA output range directly drives a steam control servo valve,eliminating intermediate relays and reducing system complexity.

Related Products

GE DS200TCQEG2A:Thermocouple input expansion board,pairs with DS215KLDBG1AZZ03A for additional temperature channels.

GE Mark V Controller(Speedtronic):Native host for the bundle,executing turbine control logic based on conditioned signals.

GE 3500/42M Vibration Transmitter:Turbine vibration sensor,whose 4-20mA output is processed by DS215KLDBG1AZZ03A.

Phoenix Contact SAC-4P-M12MS/2,0-PUR:Shielded M12 cable,ensuring noise-free signal transmission to DS215KLDBG1AZZ03A.

GE DS200STCAG1A:Mark V system timing board,synchronizes data between DS215KLDBG1AZZ03A and the controller.

Schneider Electric Square D 9001K62:24V DC power supply,feeding reliable power to both boards.

GE DS200TCQCF1A:Digital I/O companion board,extending the bundle’s capability to discrete signals.

GE ToolboxST Software:Configures DS215KLDBG1AZZ03A jumpers and logs data correlated with DS200KLDBG1ABC status.

Installation and Maintenance

Pre-Installation Preparation

Verify Mark V compatibility:Ensure the system firmware is v5.1+for seamless integration.

Match signal types:Use DS215KLDBG1AZZ03A jumpers(J5/J6)to set 20mA/200mA output ranges per field devices.

Inspect components:Check for bent pins on DS215KLDBG1AZZ03A’s 3PL/JE connectors and cracked LEDs on DS200KLDBG1ABC.

Gather tools:Prepare a precision screwdriver(for jumpers),shielded cables,and a multimeter.

Installation Steps

Mount DS215KLDBG1AZZ03A:Slide the board into the Mark V I/O core(R1/R2/R3)slot,align with the backplane,and secure with locking clips.

Wire Signals:Connect thermocouples to JAR/S/T(TBQA terminal),LVDTs to JF(TBQC terminal),and 4-20mA devices to JB(TBQC terminal).Use the 3PL connector for COREBUS communication.

Configure Jumpers:Set J1/J2 for output circuit type,J5/J6 for current range,and J7 to”TEST”only during RS232 calibration.

Mount DS200KLDBG1ABC:Attach the display board to the control cabinet door(or I/O core front panel)using M3 screws,ensuring LEDs are visible to operators.

Connect Display:Wire the board to the Mark V backplane’s status bus—align pins with”C-ESS”and”6BA01″labels for correct channel mapping.

Test System:Power on the Mark V;confirm DS215KLDBG1AZZ03A’s green”PWR”LED and DS200KLDBG1ABC’s channel LEDs illuminate.Use ToolboxST to verify signal accuracy.

Maintenance Recommendations

Monthly Checks:Inspect DS200KLDBG1ABC LEDs for dimness or burnout;tighten DS215KLDBG1AZZ03A’s terminal screws.

Quarterly Calibration:Use a precision signal generator to test DS215KLDBG1AZZ03A’s accuracy—recalibrate if drift exceeds±0.2%.

Semi-Annual Cleaning:Blow compressed air(≤0.3MPa)through DS215KLDBG1AZZ03A’s vents to remove turbine dust.

Fault Resolution:If DS200KLDBG1ABC shows a red LED,use ToolboxST to check DS215KLDBG1AZZ03A’s fault logs(common issues:overcurrent,sensor short).Hot-swap the I/O board if needed.

Product Guarantee

The DS215KLDBG1AZZ03A and DS200KLDBG1ABC bundle includes a 2-year manufacturer’s warranty covering defects in materials/workmanship under normal Mark V operation.For claims,provide the serial numbers(engraved on each board)and proof of purchase—GE offers free replacement with 48-hour expedited shipping for critical turbine applications.

Authorized distributor purchases include added value:on-site installation by GE-certified turbine technicians,jumper configuration training,and 24/7 technical support(urgent issues resolved within 2 hours).Extended warranty plans(1-3 years)cover annual calibration,LED replacement for DS200KLDBG1ABC,and priority access to GE’s Mark V service network.Each board undergoes 100%factory testing(signal accuracy,vibration resistance,LED functionality)and includes a conformance certificate for regulatory audits.Verify authenticity via GE’s Power Systems portal using the serial number.

If you need to dive deeper into industry-specific applications(e.g.,nuclear turbine compliance with 10CFR50)or clarify jumper configuration for unique signal types(e.g.,RTD inputs),feel free to share additional details.I can also expand on the bundle’s integration with GE’s Mark V to Mark VIe upgrade paths for plants modernizing their control systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!