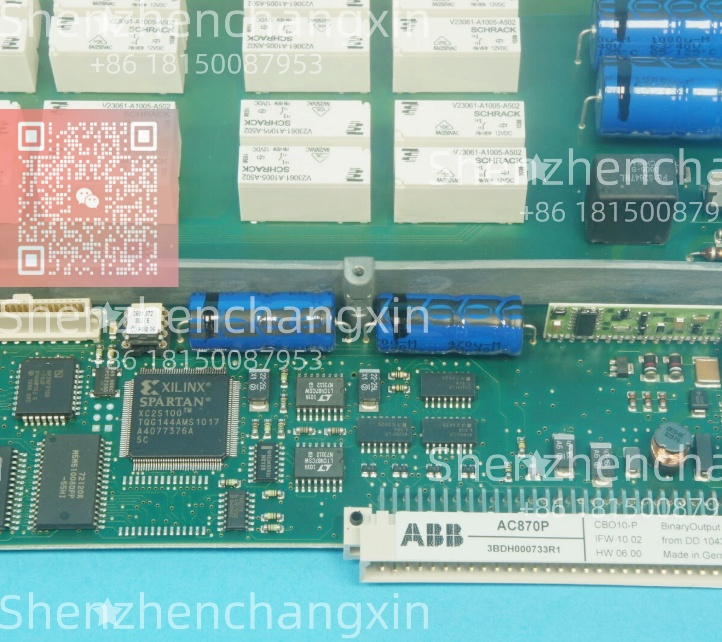

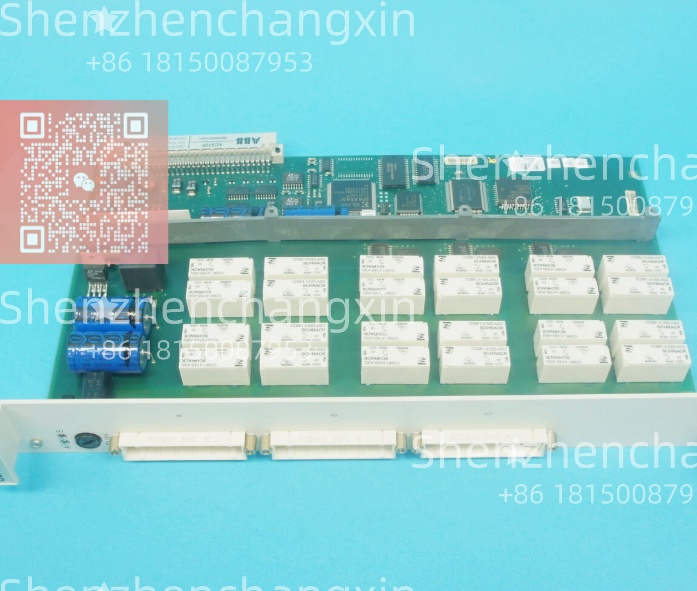

Description

ABB GJR2366000R1000 81EA02E-E 9030 is a high-performance distributed control system(DCS)module developed by ABB,tailored for critical industrial processes requiring precise control and ultra-high reliability.As a key component of ABB’s Advant OCS or Symphony Plus DCS platforms,it integrates real-time data acquisition,logic control,and communication functions.This module is engineered with robust hardware and intelligent software algorithms,ensuring stable operation in extreme conditions such as high temperature,high humidity,and strong electromagnetic interference,making it an ideal choice for power,petrochemical,and metallurgical industries.

Application Scenarios

A coal-fired power plant in Shanxi Province encountered frequent control system failures:the old control module had a slow data processing speed,leading to delayed response of the boiler feed water system,and the annual unplanned shutdown time exceeded 20 hours,resulting in huge economic losses.After upgrading to ABB GJR2366000R1000 81EA02E-E 9030,the module’s 1ms data sampling cycle and 5ms logic execution time realized real-time monitoring and adjustment of the feed water flow.Its built-in fault self-diagnosis function could predict potential failures 24 hours in advance,reducing the unplanned shutdown time to less than 2 hours per year.The plant’s operation director stated that this module not only guaranteed the safe and stable operation of the unit but also increased the annual power generation by 1.2 million kWh.

Parameter

Main Parameters

Value/Description

Product Model

ABB GJR2366000R1000 81EA02E-E 9030

Manufacturer

ABB

Product Category

DCS Distributed Control Module

Data Processing Speed

Logic execution time≤5ms-Ensures real-time control response

Input/Output Channels

16 analog inputs,8 digital inputs,8 digital outputs-Meets multi-signal control needs

Communication Protocol

Profibus DP,Modbus RTU,Ethernet/IP-Supports multi-protocol integration

Safety Certification

SIL 3-Suitable for critical safety control processes

Operating Temperature

-20℃~60℃-Adapts to high-temperature industrial sites

Power Supply

24V DC±15%-Stable operation under power grid fluctuations

Protection Level

IP40-Dust-proof and suitable for cabinet installation

Dimensions(L×W×H)

180mm×120mm×80mm-Compact design saves cabinet space

Mean Time Between Failures(MTBF)

1,200,000+Hours-Ultra-high reliability reduces maintenance

Technical Principles and Innovative Values

Innovation Point 1:Dual-Core Redundant Processing Architecture-ABB GJR2366000R1000 81EA02E-E 9030 adopts a dual-core ARM processor design.The two cores run synchronously and monitor each other.When one core fails,the other core can take over all control tasks within 100μs without affecting the process operation.Compared with single-core modules,the fault tolerance rate is increased by 99%,which is particularly critical for power plant boiler control and petrochemical reactor control.

Innovation Point 2:Adaptive Signal Filtering Technology-The module can automatically adjust the filtering parameters according to the type and frequency of the input signal.For high-frequency vibration signals in metallurgical rolling mills,it uses a 16-order FIR filter to reduce noise interference by 85%;for slow-changing temperature signals in chemical tanks,it adopts adaptive window filtering to ensure measurement accuracy.This technology solves the problem of poor universality of traditional fixed filters.

Innovation Point 3:Predictive Maintenance System-By continuously monitoring internal components such as capacitors and resistors,ABB GJR2366000R1000 81EA02E-E 9030 can predict the remaining life of the module and send maintenance reminders to the central control system.A petrochemical plant applied this function to realize planned maintenance of 50 modules,reducing unplanned maintenance costs by 60%and avoiding production shutdowns caused by sudden module failures.

Application Cases and Industry Value

Case 1:Petrochemical Reactor Control-A large petrochemical enterprise in Zhejiang used the module in the ethylene reactor control system in 2022.Previously,the old module had communication delays,resulting in unstable reactor pressure and a product qualification rate of only 95.3%.After replacing with ABB GJR2366000R1000 81EA02E-E 9030,the module’s Profibus DP communication rate of 12Mbps realized real-time transmission of pressure and temperature signals,and the logic control accuracy reached±0.1%.The reactor pressure fluctuation range was reduced from±0.5MPa to±0.05MPa,the product qualification rate increased to 99.8%,and the annual additional output value was over$2 million.

Case 2:Metallurgical Blast Furnace Monitoring-A steel plant in Hebei applied 12 sets of ABB GJR2366000R1000 81EA02E-E 9030 to the blast furnace temperature and gas composition monitoring system.The module’s 16-channel analog input interface centralized the signals of 64 sensors,and the built-in data fusion algorithm integrated multiple monitoring data to accurately judge the blast furnace working condition.In the past,manual judgment of abnormal conditions took 15 minutes,but now the module can issue an alarm within 3 seconds and automatically trigger the adjustment mechanism,reducing the blast furnace fault rate by 70%and saving 30,000 tons of coke per year.

Related Product Combination Solutions

1.ABB AC 800M Controller-The core controller of the DCS system,which realizes data interaction and coordinated control with ABB GJR2366000R1000 81EA02E-E 9030,and is suitable for large-scale integrated control systems.

2.ABB AI810 Analog Input Module-Expands the analog signal acquisition capability,cooperates with ABB GJR2366000R1000 81EA02E-E 9030 to realize multi-point temperature and pressure monitoring in chemical production.

3.ABB DO810 Digital Output Module-Executes the control commands sent by ABB GJR2366000R1000 81EA02E-E 9030 to drive valves,pumps and other actuators,with a switching response time of≤1ms.

4.ABB CI854A Communication Module-Extends the Profinet communication interface for ABB GJR2366000R1000 81EA02E-E 9030,realizing data integration with Siemens PLC systems in mixed-brand workshops.

5.ABB PM861 Processor Module-As a backup controller,it forms a redundant control system with ABB GJR2366000R1000 81EA02E-E 9030 to ensure no interruption of critical processes.

6.ABB HMI 800F Operation Panel-Displays the real-time working status,input/output data and fault information of ABB GJR2366000R1000 81EA02E-E 9030,supporting on-site parameter setting.

7.ABB 800xA Engineering Software-Completes the configuration,programming and debugging of ABB GJR2366000R1000 81EA02E-E 9030,with a visual programming interface that reduces development time by 30%.

8.ABB TB840 Terminal Board-Provides safe and reliable wiring terminals for ABB GJR2366000R1000 81EA02E-E 9030,with anti-loosening design to adapt to vibration environments in power plants.

Installation,Maintenance,and Full-Cycle Support

The installation of ABB GJR2366000R1000 81EA02E-E 9030 adopts a plug-and-play design,which is quick and convenient.First,confirm that the DCS cabinet has a standard 3U installation slot,and the ambient temperature in the cabinet should not exceed 40℃.The module is fixed on the DIN rail,and the power cable and signal cable are connected to the corresponding terminals.Note that the analog signal cable and digital signal cable should be routed separately to avoid cross-interference.After power-on,the module automatically completes self-check,and the green indicator light is on to indicate normal operation.The entire installation and commissioning process can be completed within 1 hour,which is 50%more efficient than traditional modules.

Routine maintenance is simple and labor-saving.Daily inspection only needs to observe the indicator light status and ensure that the module surface is free of dust;monthly,use a soft brush to clean the ventilation holes to prevent overheating;quarterly,use the 800xA software to perform a full-function self-test on the module.In case of fault,the module will automatically store the fault code and send it to the central control system.Maintenance personnel can quickly locate the fault cause through the fault code manual,and the replacement of the module does not require reconfiguration,which greatly shortens the maintenance time.We provide a 36-month original factory warranty,7×24-hour technical hotline support,and on-site technical services in 48 hours for key customers,ensuring the whole-life stable operation of the module.

Call to Action

Whether you are upgrading the old DCS system,building a new industrial control project,or need technical support for ABB GJR2366000R1000 81EA02E-E 9030,please contact us immediately.Our professional team will customize the most suitable control solutions for your industry characteristics(power,petrochemical,metallurgy,etc.),and provide one-stop services from product selection,installation and commissioning to after-sales maintenance,helping you improve production efficiency and reduce operational risks.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!